Sensor, sensor unit, and method for producing sensor unit

A sensor unit, sensor element technology, applied in instruments, special recording/indicating devices, equipment with special mechanical means, etc., can solve problems such as damage and interference with sensor measurement performance, and achieve the effect of reducing cost and high signal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

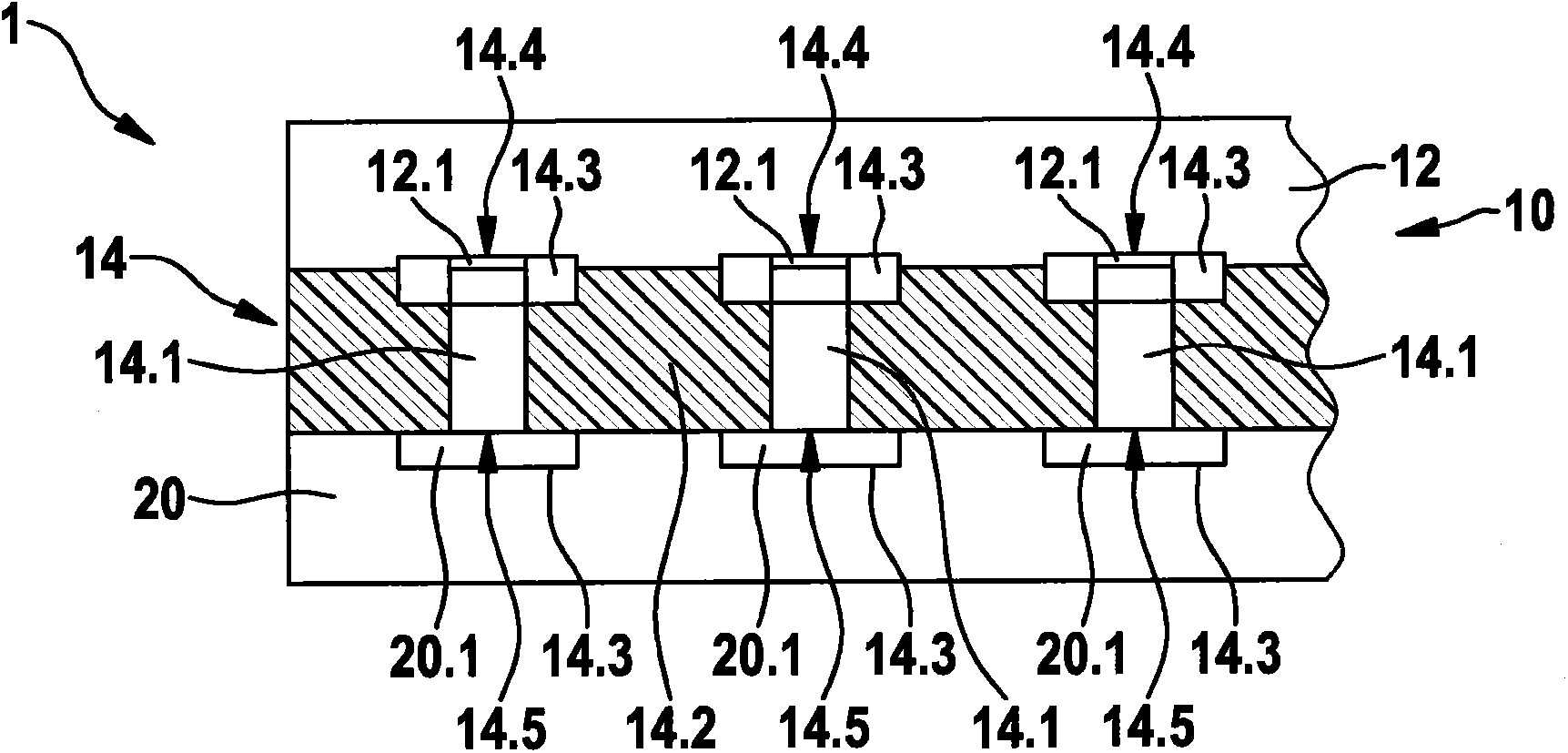

[0027] From Figure 1 to Figure 10 It can be seen that the illustrated exemplary embodiments of sensor units 1 , 1 ′ each comprise a circuit board 20 , 20 ′ and sensors 10 , 10 ′ with sensor elements 12 , 12 ′ for measuring physical quantities.

[0028] According to the invention, the sensor 10 , 10 ′ comprises at least one elastic damping element 14 , 14 ′ which damps external disturbance vibrations or disturbance frequencies and which has an electrical connection for realizing the sensor element 10 , 10 ′. Contacting and / or mechanical contacting means 14.1, 14.1'. Elastic damping elements 14 , 14 ′ are arranged between printed circuit board 20 and sensor element 12 , and together with sensor elements 12 , 12 ′ form sensors 10 , 10 ′ in the exemplary embodiment shown.

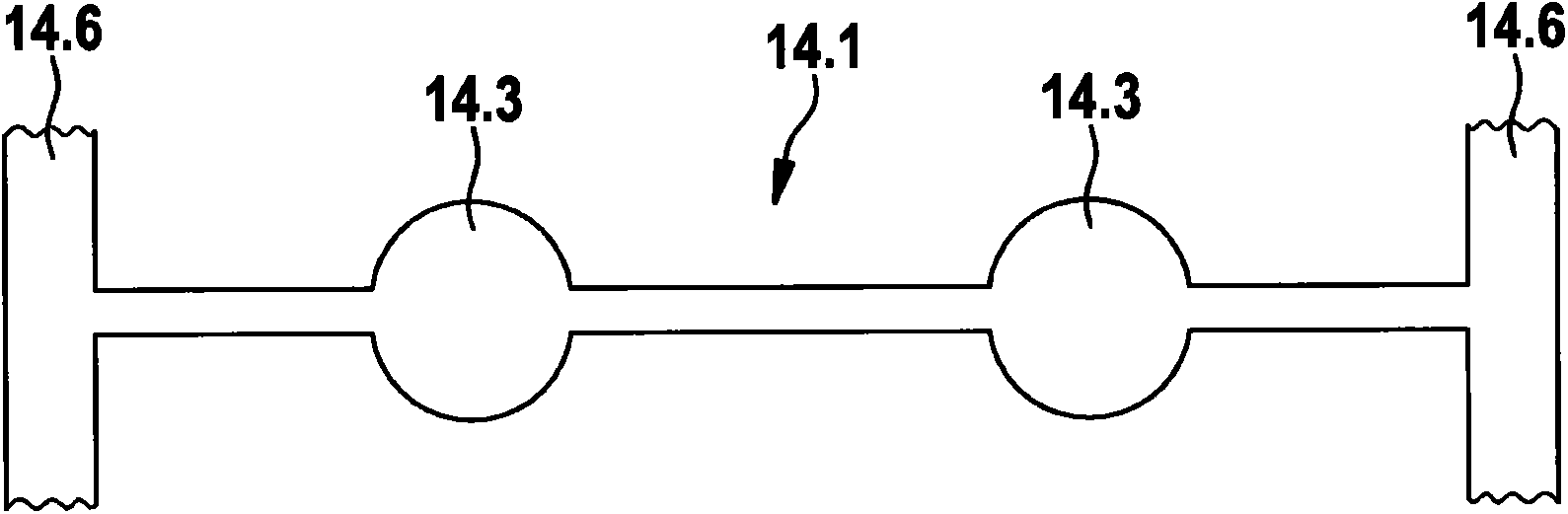

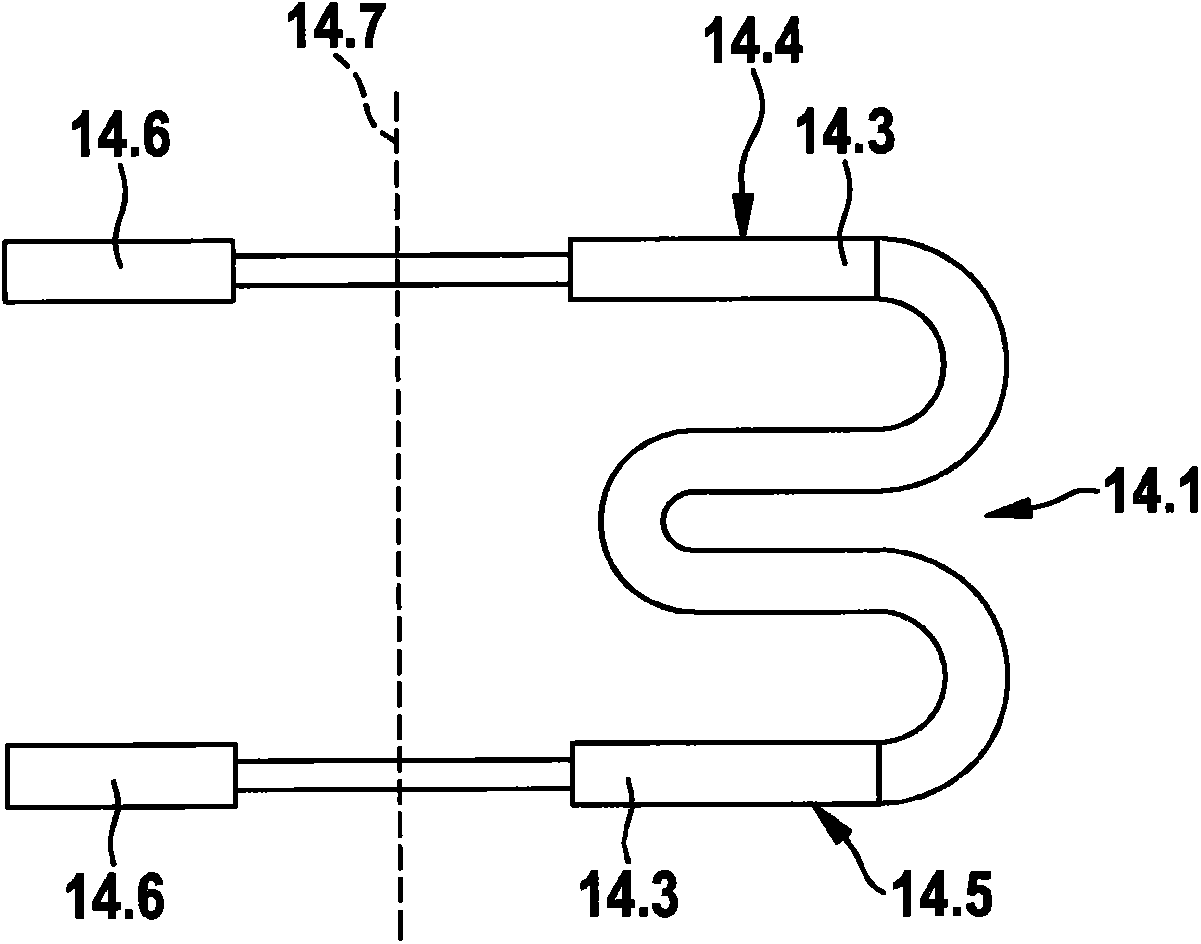

[0029] From Figures 1 to 9 It can also be seen that in the first exemplary embodiment the elastic damping element 14 has at least one spring element 14.1 with two contact elements 14.3. All spring elements 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com