Method for preparing modified isocyanate mixture containing carbodiimide and/or uretonimine derivatives

A technology of carbodiimide and carbodiimide catalyst is applied in the field of preparing modified isocyanate mixture with improvement, and can solve the problems such as rapid decrease of NCO content, increase of viscosity, unsatisfactory appearance and color number of products, etc. Achieve the effect of good storage stability at room temperature and optimized reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

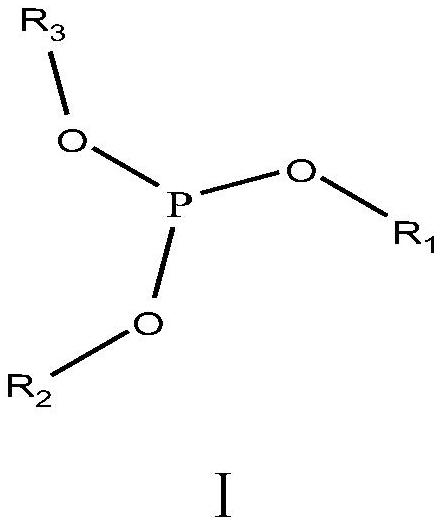

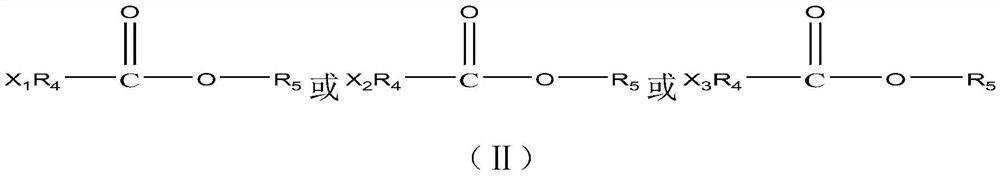

Method used

Image

Examples

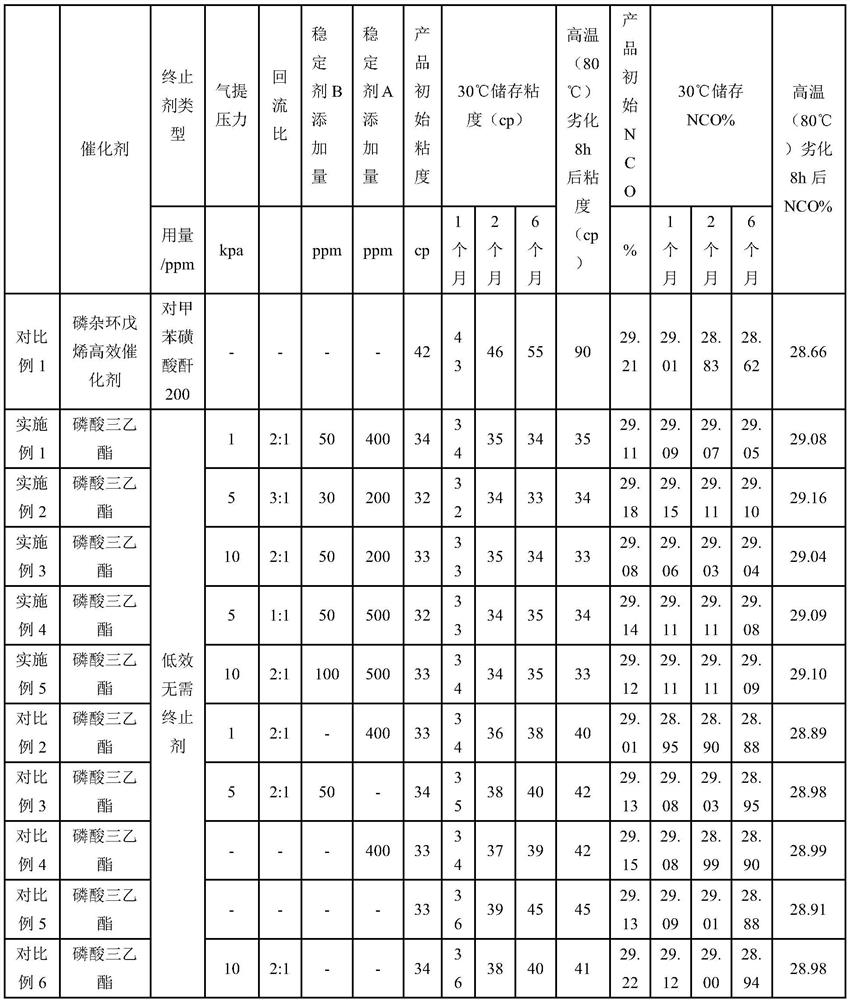

Embodiment 1

[0048] 500g diphenylmethane diisocyanate in N 2 Heat to about 50°C while stirring under protection, add 2.5% phosphate ester low-efficiency catalyst, heat up to 205°C quickly after mixing, pass nitrogen gas into the reaction process for stripping, keep the system pressure at 1kpa, and cool the tail gas with a condenser , keep the amount of condensate returned to the system at a reflux ratio of 2:1, react for 180 minutes and reverse diphenylmethane diisocyanate 400g, cool the temperature to 40°C, add 400ppm of triphenyl phosphite and 50ppm of chlorobenzene Phenyl methanesulfonate, the final product.

Embodiment 2

[0050] 500g diphenylmethane diisocyanate in N 2 Heat to about 50°C while stirring under protection, add 2.5% phosphate ester low-efficiency catalyst, heat up to 190°C quickly after mixing, and nitrogen gas is introduced during the reaction process to keep the system pressure at 5kpa, and the tail gas is cooled with a condenser , keep the amount of condensate returned to the system at a reflux ratio of 3:1, react for 240 minutes and reverse diphenylmethane diisocyanate 400g, cool the temperature to 40°C, add 200ppm of trimethyl phosphite and 30ppm of chlorobenzene Phenyl methanesulfonate, the final product.

Embodiment 3

[0052] 500g diphenylmethane diisocyanate in N 2 Heat to about 50°C while stirring under protection, add 2.5% phosphate ester low-efficiency catalyst, heat up to 205°C quickly after mixing, and nitrogen gas is introduced during the reaction process to keep the system pressure at 10kpa, and the tail gas is cooled with a condenser , keep the amount of condensate returned to the system at a reflux ratio of 2:1, react for 180 minutes and reverse diphenylmethane diisocyanate 400g, cool the temperature to 50°C, add 200ppm tricresyl phosphite and 50ppm diisocyanate Ethyl chlorophosphate, the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com