Single-component motor adhesive capable of being stably stored at normal temperature and rapidly cured at medium temperature and preparation method of single-component motor adhesive

An adhesive, one-component technology, applied in the field of adhesives, can solve problems such as increased storage and transportation costs, increased quality risks during use, and impact on product use and promotion, and achieves good storage stability at room temperature and good versatility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0034] The present embodiment provides an imidazole copper salt coordination complex, and its preparation process includes the following steps:

[0035] S1, the imidazole, NaHCO 3 It is mixed with distilled water in a weight ratio of 10:35:250, and heated at 80°C to dissolve to obtain a clear, colorless and transparent imidazole solution.

[0036] S2, the same weight of Cu(CH as biimidazole) 3 COO) 2 .H 2 O was dissolved in 10 times the weight of distilled water, slowly added dropwise to the imidazole solution, keeping the water bath boiling, after the dropwise addition, the water bath was heated for 1h, cooled to room temperature, the precipitate was collected, washed, and vacuum dried for 3h to obtain blue powder imidazole Ketone salt coordination complex.

Embodiment 1-2

[0038] The present embodiment provides a biimidazole copper salt coordination complex, and its preparation process includes the following steps:

[0039] S1, add 30 g of biimidazole to 2500 mL of DMF, and heat under reflux to dissolve it completely to obtain a pale yellow biimidazole solution.

[0040] S2, 40 g of Cu (CH 3 COO) 2 .H 2 O was added to 500 mL of DMF to form a solution, which was slowly added dropwise to the biimidazole solution, heated to reflux for 3 h, cooled to room temperature, collected and washed with the precipitate, and dried in vacuum for 3 h to obtain a beige powder of biimidazole copper salt coordination complex.

Embodiment 2-1

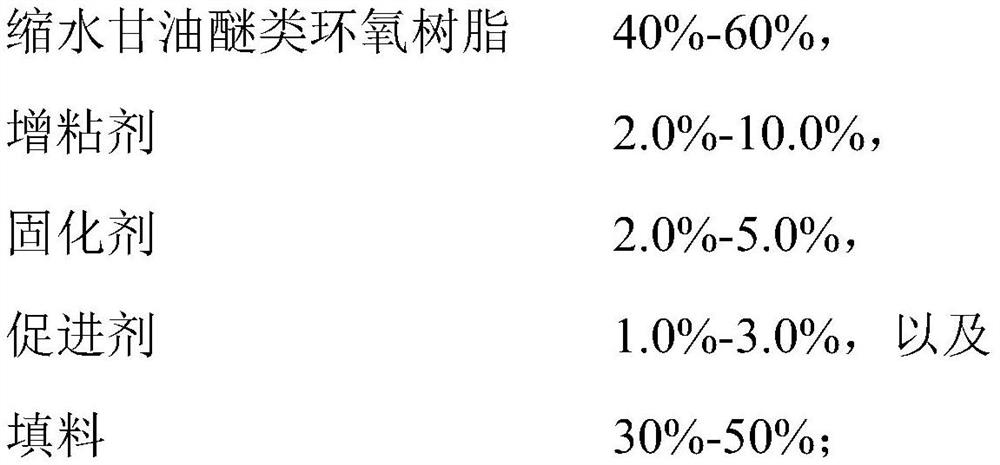

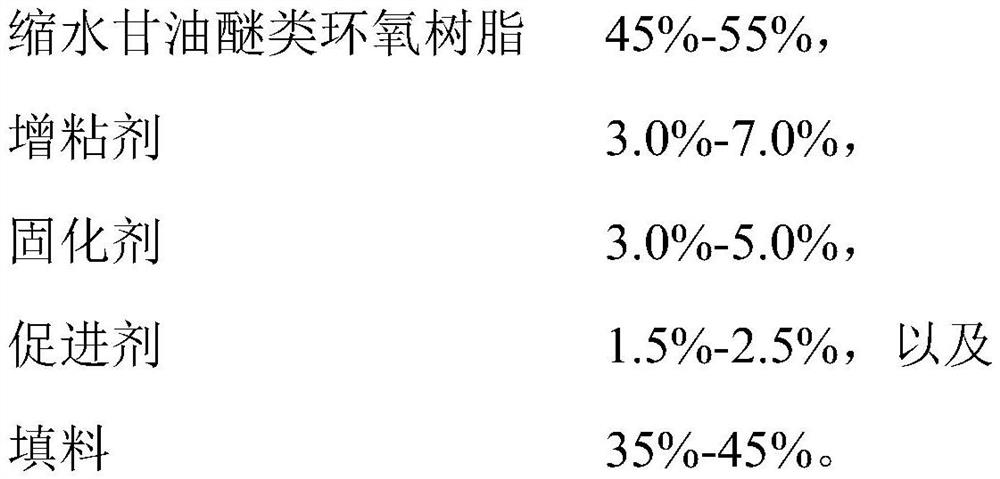

[0042] This embodiment provides a one-component motor adhesive, and its raw material composition is shown in Table 1 below:

[0043] Table 1 Example 2-1 Composition table of motor adhesive

[0044]

[0045] The preparation method of the motor adhesive of this embodiment includes the following steps:

[0046] S1, each raw material is weighed according to the composition of the motor adhesive in Table 1.

[0047] S2, stirring the glycidyl ether epoxy resin and the tackifier at 55±5° C. to completely dissolve the materials to obtain a liquid mixture.

[0048] S3, the liquid mixture, curing agent, accelerator and filler are added into the dynamic mixer, and the reaction is stirred at 35±5°C. The process parameters of the stirring reaction are: revolution frequency 15Hz, rotation frequency 15Hz, and stirring reaction time is 35min. Then carry out vacuum defoaming, and the process parameters of vacuum defoaming are: vacuum pressure to -0.09Mpa or more, stirring time 35min, that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com