Method for producing isocyanate

A technology of isocyanate and crude isocyanate, which is applied in the field of isocyanate production, can solve the problems of not describing the purity of circulating solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

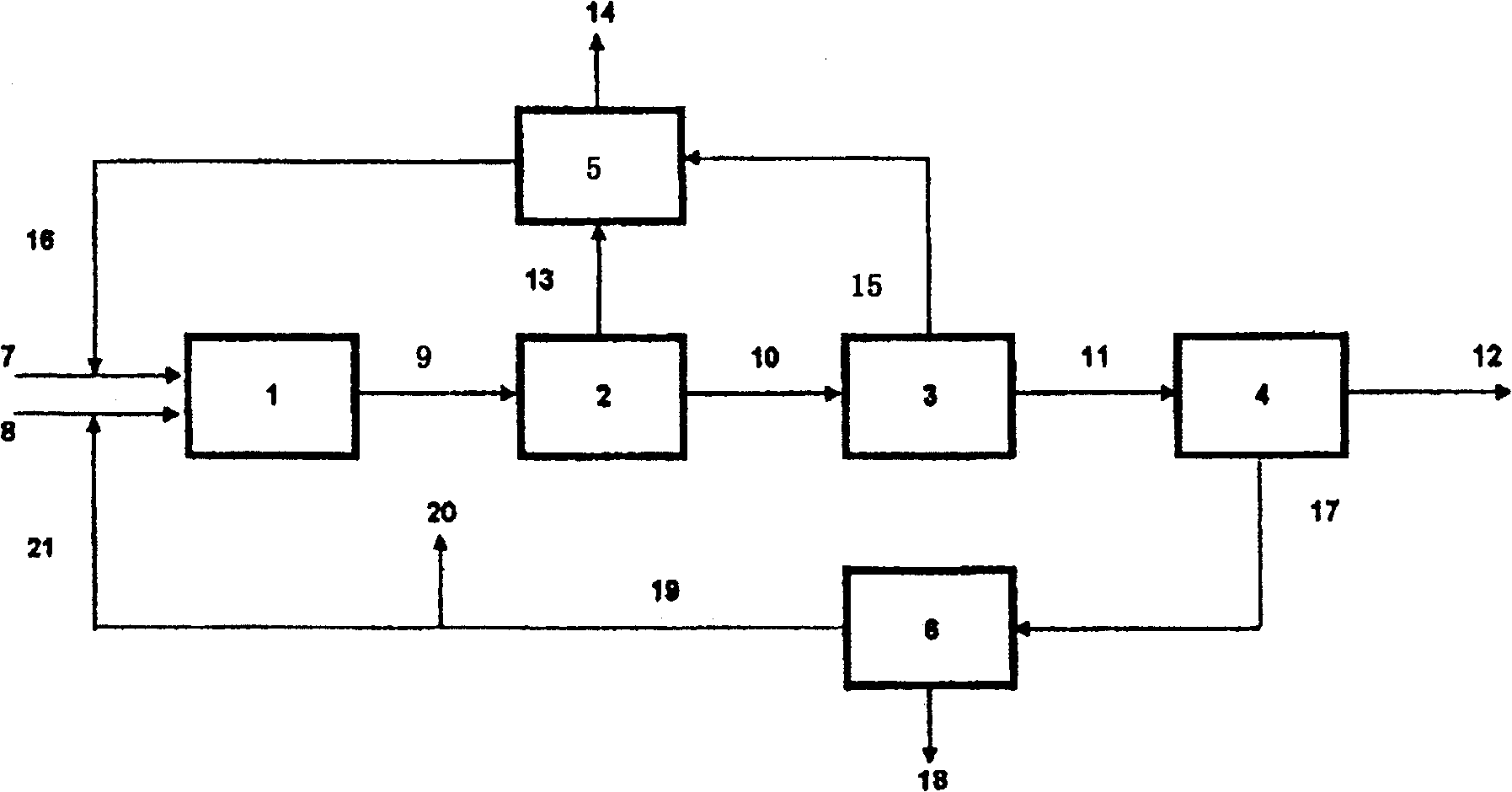

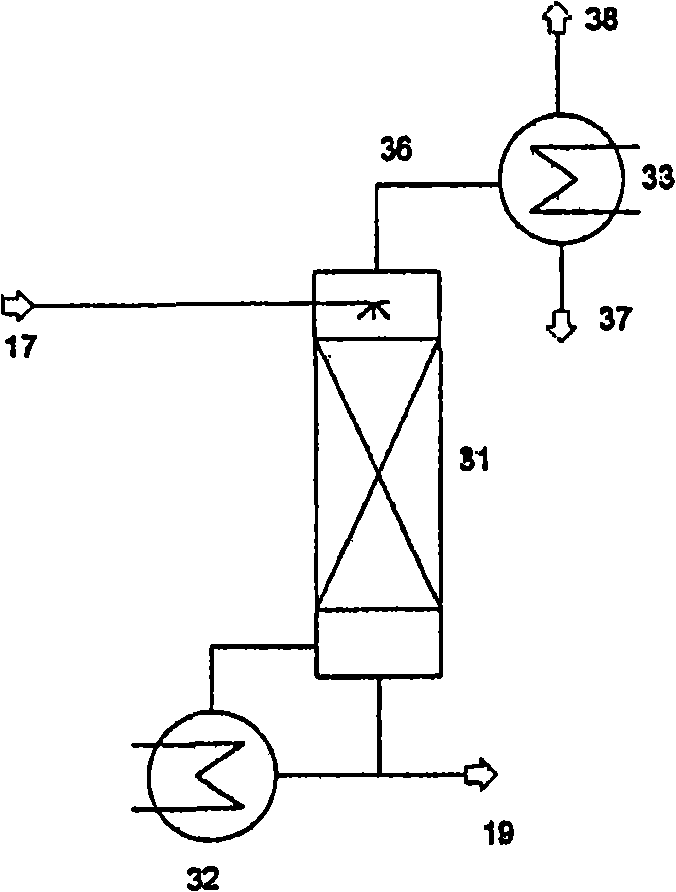

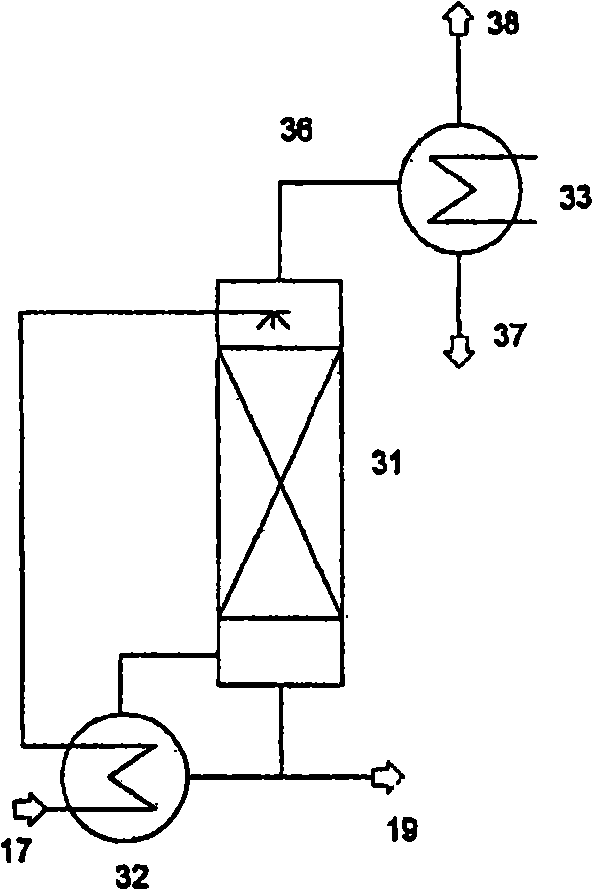

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 (Preparation of a mixture of diamine and polyamine)

[0035] In a stirred container, 2600 grams of aniline and 1000 grams of formalin (based on the weight of the solution, 30% by weight aqueous formaldehyde solution) are thoroughly mixed under stirring and at 25°C, during which time the mixture is heated To 60°C. Turn off the stirrer, and separate and remove the water phase stabilized on the upper part. Then, 68 g of a 30% by weight hydrochloric acid aqueous solution was mixed in, while stirring and cooling, and the temperature was maintained at 45°C. Stirring was continued at this temperature for 15 minutes, and heating was used instead of cooling. The mixture was uniformly heated to 140°C under a pressure of 5 bar within 120 minutes, and maintained at this temperature for 15 minutes.

[0036] Then, the mixture was cooled to 100°C, reduced to normal pressure, and 54 g of a 50% by weight aqueous sodium hydroxide solution was added for neutralization while stirri...

Embodiment 2

[0042] Example 2 (Use contaminated solvent to produce a mixture of diisocyanate and polyisocyanate (not according to the invention))

[0043] In a stirred reactor, the mixture of 1900 g of diamine and polyamine obtained in Example 1 was dissolved in 5700 g of chlorobenzene. The phosgene content was 200 ppm based on the weight of the solvent chlorobenzene. MDI The content is 200ppm. In a second container made of stainless steel (DIN 1.4571), a 33% by weight (based on the weight of the solution) phosgene solution was prepared by dissolving 3800 grams of phosgene in 7600 grams of chlorobenzene, while cooling to At 0°C, mix the amine with the phosgene solution while stirring vigorously. The resulting solid suspension is then slowly heated to form hydrogen chloride gas, which is collected by a suitable device. During this process, a homogeneous polyisocyanate solution is formed. The solvent was separated and removed by distillation, and as a result, a mixture of 2370 grams of diisocy...

Embodiment 3

[0051] Example 3 (Use pure solvent to produce a mixture of diisocyanate and polyisocyanate (according to the present invention))

[0052] In a stirred reactor, the mixture of 1900 g of diamine and polyamine obtained in Example 1 was dissolved in 5700 g of chlorobenzene. Based on the weight of the solvent chlorobenzene, the phosgene content was 20 ppm, and MDI The content is 20 ppm. In a second container made of stainless steel (DIN 1.4571), a 33% by weight (based on the weight of the solution) phosgene solution was prepared by dissolving 3800 grams of phosgene in 7600 grams of chlorobenzene, while cooling to At 0°C, while stirring vigorously, mix the amine with the phosgene solution. The resulting solid suspension is then slowly heated to form hydrogen chloride gas, which is collected by a suitable device. During this process, a homogeneous polyisocyanate solution is formed. The solvent was removed by distillation, and as a result, a mixture of 2370 grams of diisocyanate and poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com