Hyperbranched polysiloxane grafted graphene/bismaleimide composite material and preparation method thereof

A technology of bismaleimide and polysiloxane is applied in the field of hyperbranched polysiloxane grafted graphene/bismaleimide composite material and preparation, and can solve the problem of high viscosity and unfavorable graphene dispersion. , high curing temperature, to achieve the effect of improving dispersibility, improving mechanical properties and friction properties, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

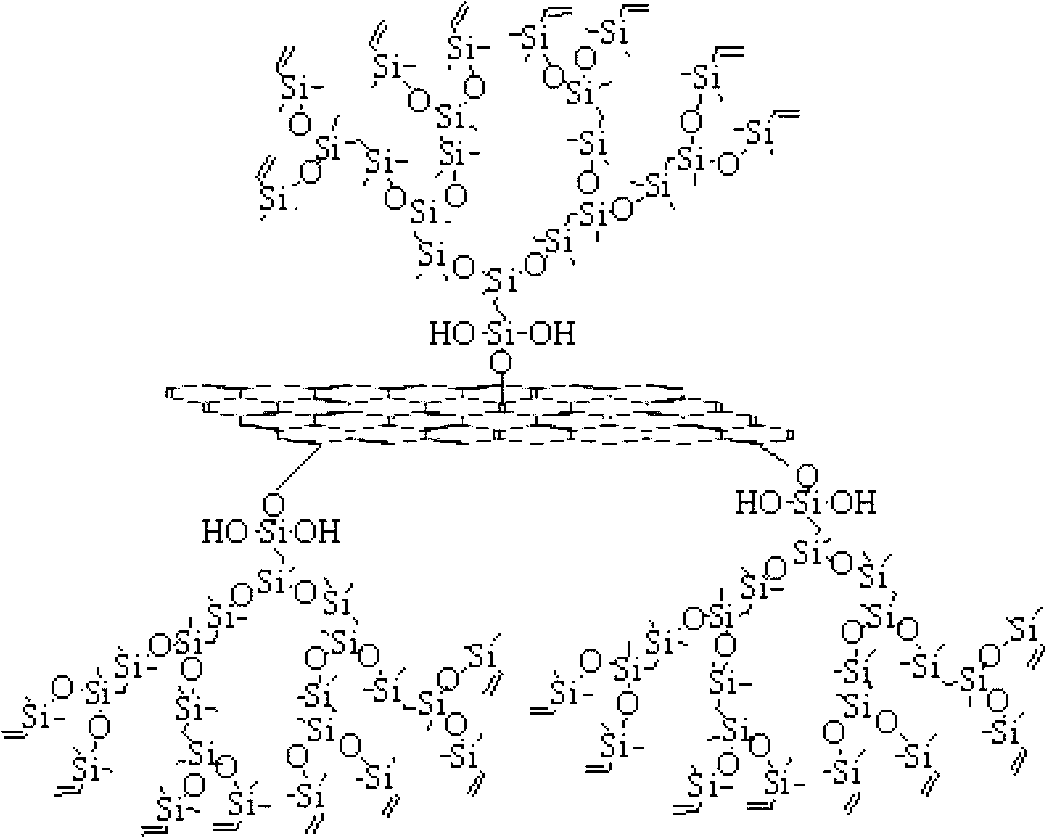

[0031] (1) Add vinyltriethoxysilane-grafted graphene and methylbis(dimethylvinylsiloxy)silane into a three-necked flask at a mass ratio of 1:400, and add 0.1~4%Pt / C The catalyst was reacted at 50° C. for 8 hours under the condition of nitrogen protection, suction filtered, and washed with ethanol to obtain hyperbranched polysiloxane-modified graphene.

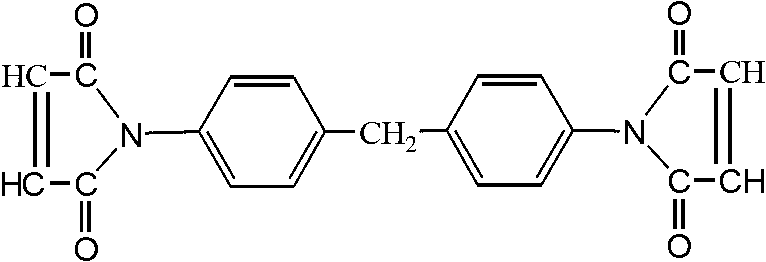

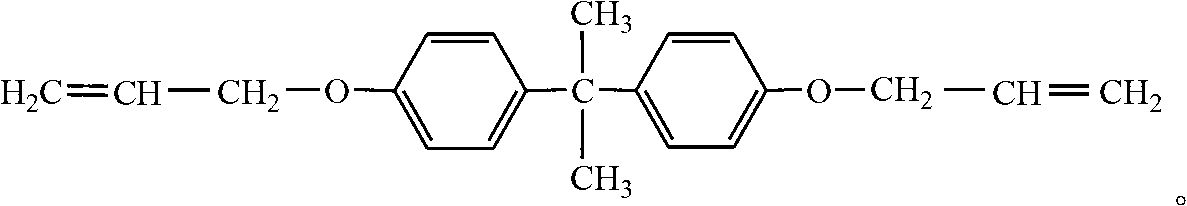

[0032] (2) Ultrasonic dispersion of 0.1 parts of hyperbranched polysiloxane-modified graphene, 100 parts of diphenylmethane type bismaleimide and 30 parts of bisphenol A diallyl ether at a power of 50~70W After 10~60min, heat and melt at 60~120℃, prepolymerize for 15~60min, pour into the preheated mold, put it into a vacuum box at 80~120℃, vacuumize to remove air bubbles, and put it into a blast drying oven Carry out staged heating and curing, the curing process is 120°C / 2h+140°C / 2h+160°C / 2h+180°C / 2h, then naturally cool, after demoulding, post-treatment at 200°C for 2 hours to obtain hyperbranched polysilicon Oxane-grafted gr...

Embodiment 2

[0034] (1) The preparation method of hyperbranched polysiloxane-modified graphene is the same as in Example 1.

[0035] (2) Ultrasonic dispersion of 0.5 parts of hyperbranched polysiloxane-modified graphene, 100 parts of diphenylmethane type bismaleimide and 40 parts of bisphenol A diallyl ether at a power of 50~70W After 10~60min, heat and melt at 60~120℃, prepolymerize for 15~60min, pour into the preheated mold, put it into a vacuum box at 80~120℃, vacuumize to remove air bubbles, and put it into a blast drying oven Carry out staged heating and curing, the curing process is 120°C / 2h+140°C / 2h+160°C / 2h+180°C / 2h, then naturally cool, after demoulding, post-treatment at 200°C for 2h to obtain hyperbranched polysilicon Oxane-grafted graphene / bismaleimide composites.

Embodiment 3

[0037] (1) The preparation method of hyperbranched polysiloxane-modified graphene is the same as in Example 1.

[0038](2) Ultrasonic dispersion of 1 part of hyperbranched polysiloxane-modified graphene, 100 parts of diphenylmethane type bismaleimide and 50 parts of bisphenol A bisallyl ether at a power of 50~70W After 10~60min, heat and melt at 60~120℃, prepolymerize for 15~60min, pour into the preheated mold, put it into a vacuum box at 80~120℃, vacuumize to remove air bubbles, and put it into a blast drying oven Carry out staged heating and curing, the curing process is 120°C / 2h+140°C / 2h+160°C / 2h+180°C / 2h, then naturally cool, after demoulding, post-treatment at 200°C for 2 hours to obtain hyperbranched polysilicon Oxane-grafted graphene / bismaleimide composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com