Hydrogenation catalyst and preparation method of 4,4'-diamino-dicyclohexyl methane

A dicyclohexylmethane and hydrogenation catalyst technology, which is applied in the preparation of amino compounds, metal/metal oxide/metal hydroxide catalysts, organic compounds, etc., can solve the problems that are not conducive to large-scale application and the preparation process is difficult to control , Catalyst preparation method is complex and other issues, to achieve the effect of increased product yield, simple preparation method, easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

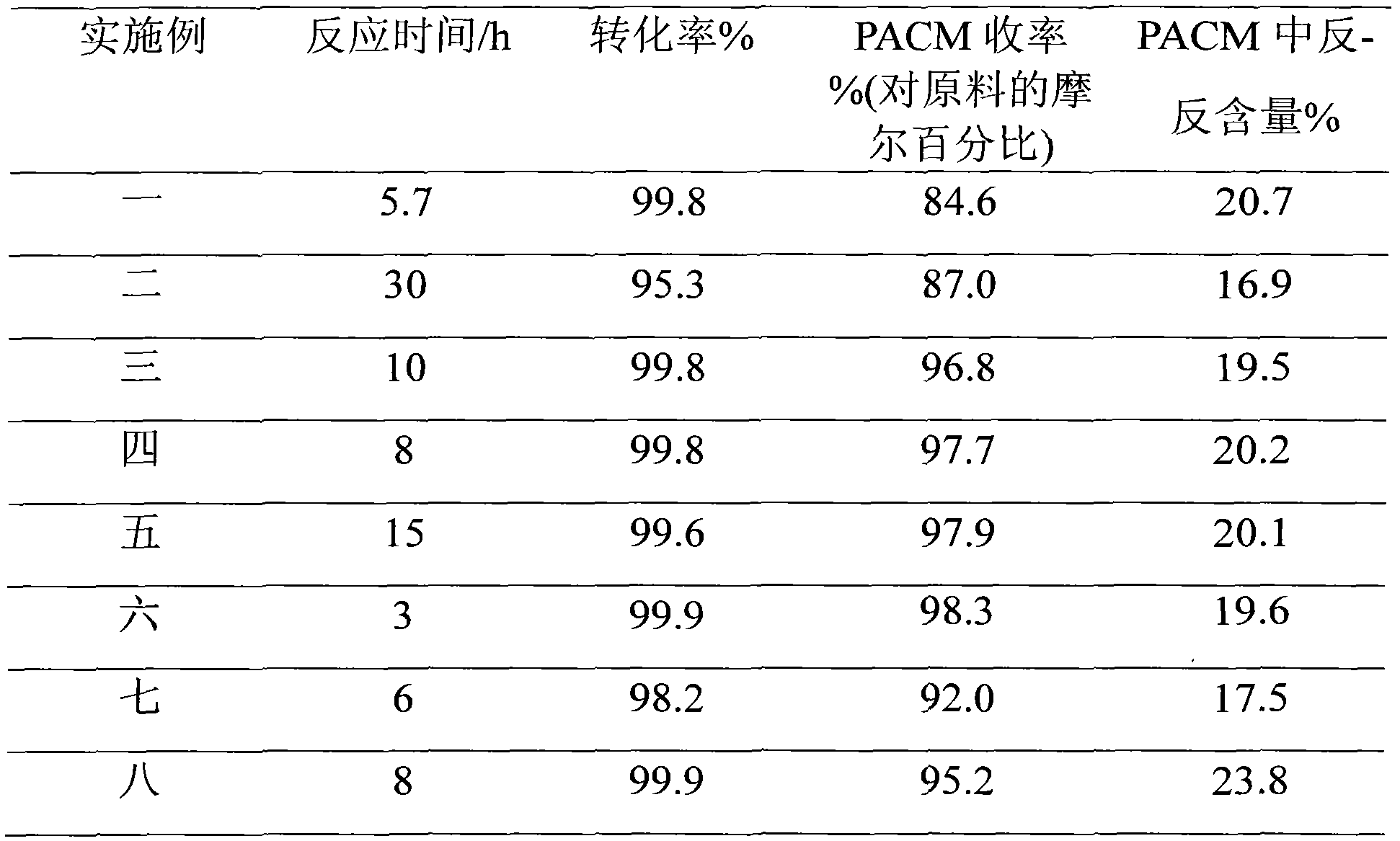

Examples

Embodiment 1

[0019] Embodiment one: in the autoclave with stirring, add 0.2g of 5% Ru / mesoporous carbon catalyst (the pore volume of carrier mesoporous carbon is 2.0mL / g, specific surface area is 1500m 2 / g, the pore diameter is 5nm, the carrier mesoporous carbon is not pretreated,), 4,4'-diaminodiphenylmethane 5g, tetrahydrofuran 32.5ml, add auxiliary agent potassium hydroxide 0.6g, close the reaction kettle, use nitrogen Replace the air in the reactor for three times, then replace the nitrogen in the reactor with hydrogen for three times, then fill the reactor with hydrogen to make the reaction pressure of the reactor reach 8.0MPa, heat the reactor to make the reaction temperature reach 140°C, start stirring, and react at a constant temperature until Until the pressure no longer drops, the reaction product is taken out, the catalyst is removed by filtration, and analyzed by gas chromatography.

Embodiment 2

[0020] Embodiment two: in the autoclave with agitation, add 0.2g of 5%Ru / mesoporous carbon catalyst (carrier mesoporous carbon is pretreated with 1M hydrochloric acid for 24 hours, the pore volume of carrier mesoporous carbon is 1.7mL / g, The specific surface area is 1800m 2 / g, pore diameter is 4nm,), 4,4'-diaminodiphenylmethane 5g, tetrahydrofuran 32.5ml, without adding additives, close the reactor, replace the air in the reactor with nitrogen for three times, and then replace the reaction with hydrogen Nitrogen in the kettle for three times, and then filled with hydrogen to make the reaction pressure of the reaction kettle reach 8.0MPa, heat the reaction kettle to make the reaction temperature reach 90°C, start stirring, keep the constant temperature reaction until the pressure no longer drops, take out the reaction product, filter to remove the catalyst , analyzed by gas chromatography.

Embodiment 3

[0021] Embodiment three: in the autoclave with stirring, add 0.2g of 5%Ru / mesoporous carbon catalyst (carrier mesoporous carbon is pretreated with 6M hydrochloric acid for 2 hours, the pore volume of carrier mesoporous carbon is 2.4mL / g, The specific surface area is 1400m 2 / g, pore diameter is 7nm,), 4,4'-diaminodiphenylmethane 5g, tetrahydrofuran 32.5ml, add auxiliary agent lithium hydroxide 0.5, close the reactor, replace the air in the reactor with nitrogen three times, and then use Replace the nitrogen in the reactor with hydrogen for three times, then fill the reactor with hydrogen to make the reaction pressure of the reactor reach 8.0MPa, heat the reactor to make the reaction temperature reach 120°C, start stirring, keep the temperature until the pressure no longer drops, take out the reaction product, The catalyst was removed by filtration and analyzed by gas chromatography.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com