Preparation method of polyurethane foam materials based on liquefied lignin calcium sulfonate polyalcohol

A technology of calcium lignosulfonate and polyurethane foam is applied in the field of preparation of polyurethane foam materials, which can solve the problems of environment and cost restricting the further application of lignin, and achieve the effects of less environmental pollution and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

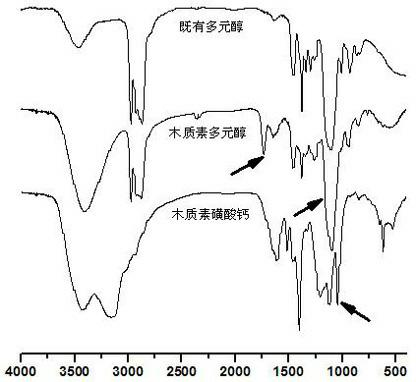

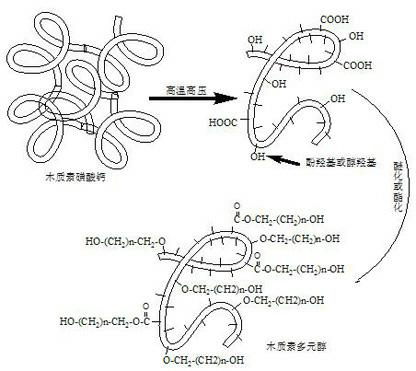

Method used

Image

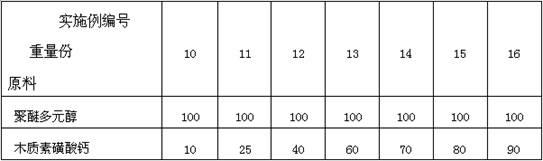

Examples

Embodiment 1

[0031] Add 100 parts (parts by weight, the same hereinafter) polyether polyol GR-4110G (produced by the third chemical plant of Shanghai Gaoqiao Petrochemical Company, the same hereinafter) into the autoclave, and add 20 parts of calcium lignosulfonate at a temperature of 150 Liquefaction reaction at ℃ for 1 hour to obtain liquefied lignin polyol; its hydroxyl value is 448.1mg(KOH).g -1 , The viscosity is 320.8mPa.s;

[0032] Then 100 parts of liquefied lignin polyol were mixed with 2.5 parts of foaming agent (water), 0.8 parts of foam stabilizer and 0.2 parts of catalyst triethylenediamine in sequence for one minute, then 0.3 parts of catalyst stannous octoate were added and stirred for 30 Second, make it as component A; weigh crude diphenylmethane-4,4'-diisocyanate (MDI) as component B, and adjust the isocyanate index (the speed of the pump for component A and component B) to 0.95 (That is: the weight ratio of component A: component B is 0.95:1), start the machine (high-pressur...

Embodiment 2

[0034] Add 100 parts (parts by weight, the same hereinafter) polyether polyol GR-4110G into the autoclave, add 50 parts of calcium lignosulfonate, and liquefy and react at 170°C for 2 hours to obtain liquefied lignin polyol; Hydroxyl value 470.7mg(KOH).g -1 , The viscosity is 560.5mPa.s;

[0035] Then 100 parts of liquefied lignin polyol were mixed with 3.5 parts of foaming agent (water), 1.0 part of foam stabilizer, 0.4 parts of catalyst triethylenediamine and stirred for one minute, then 0.4 parts of catalyst stannous octoate were added and stirred for 30 Second, make it as component A; weigh the crude diphenylmethane-4,4'-diisocyanate (MDI) as component B, and adjust the isocyanate index (speed of A and B feed pumps) to 1.0 (ie: A Components: The weight ratio of component B is 1.0:1), start the machine (high-pressure foaming machine), foam, and mature (leave for 2-10 days) to obtain polyurethane foam. The apparent density of the polyurethane foam material is 18kg.m 3 , Tensil...

Embodiment 3

[0037] Add 100 parts (parts by weight, the same hereinafter) polyether polyol GR-4110G into the autoclave, add 70 parts of calcium lignosulfonate, and liquefy and react at a temperature of 180°C for 3 hours to obtain liquefied lignin polyol; Hydroxyl value 560.5mg(KOH).g -1 , The viscosity is 752.3mPa.s;

[0038] Then 100 parts of liquefied lignin polyol were mixed with 4.0 parts of foaming agent (water), 1.2 parts of foam stabilizer, and 0.6 parts of catalyst triethylenediamine in sequence and stirred for one minute, then 0.5 parts of catalyst stannous octoate were added and stirred for 30 Second, make it as component A; weigh the crude diphenylmethane-4,4'-diisocyanate (MDI) as component B, and adjust the isocyanate index (speed of A and B feed pumps) to 1.0 (ie: A Components: The weight ratio of component B is 1.0:1), start the machine (high-pressure foaming machine), foam, and mature (place 2-10 days) to obtain polyurethane foam; the appearance of the polyurethane foam The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com