Processes for the preparation of isocyanates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

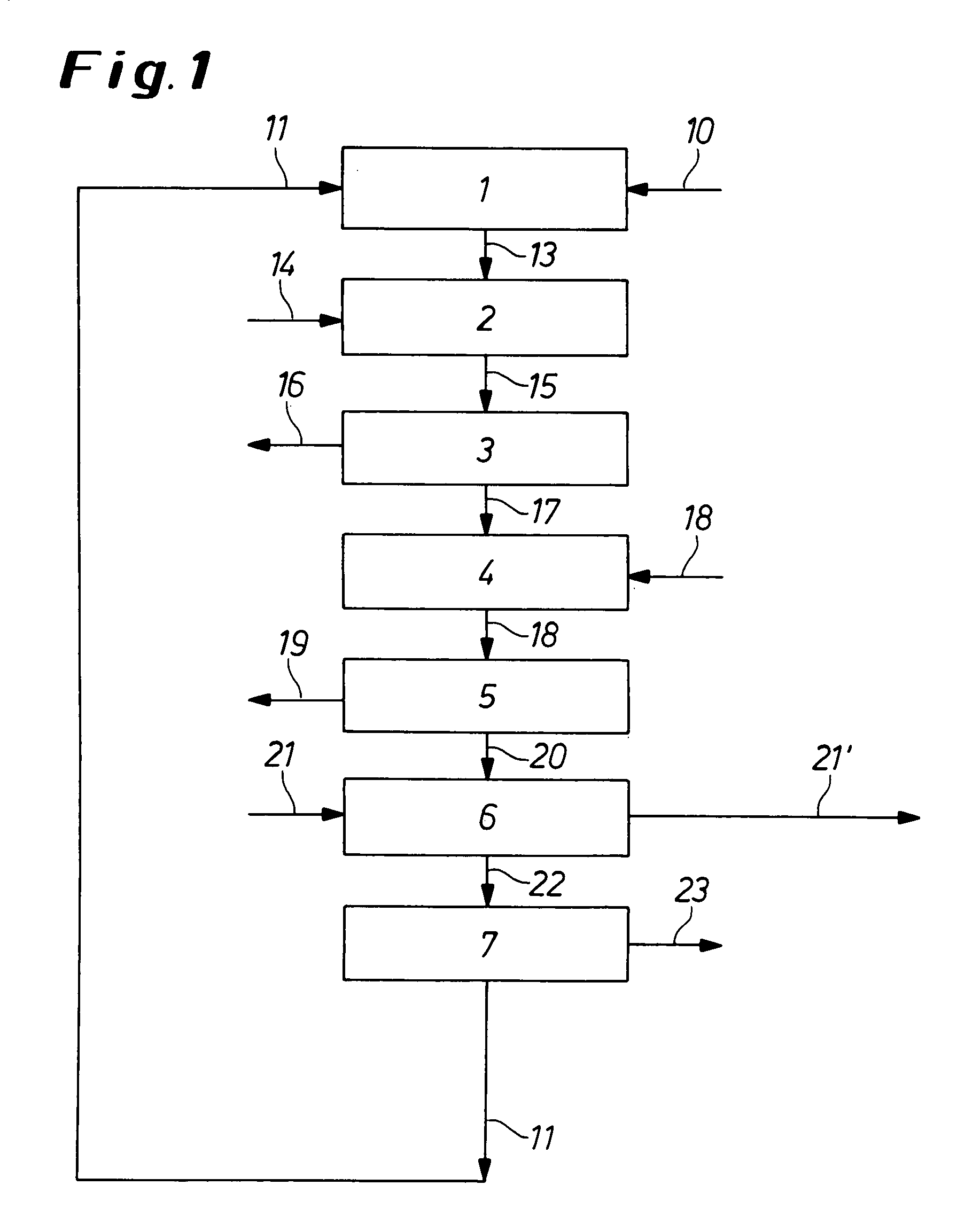

[0071] A process according to an embodiment of the invention is explained in more detail with reference to FIG. 1. FIG. 1 is a representative flowchart depicting a process according to the invention for the preparation of TDI.

[0072] In a first stage 1 of the preparation of isocyanates, chlorine 11 is reacted with carbon monoxide 10 to give phosgene 13. In the following stage 2, phosgene 13 from stage 1 is reacted with an amine 14 (in this case toluenediamine) to give a mixture 15 of isocyanate (toluene-diisocyanate, TDI) and hydrogen chloride, the isocyanate 16 is separated off (in stage 3) and utilized. The HCl gas 17 is reacted with oxygen 18 in the HCl oxidation process 4.

[0073] For this e.g., a UV-transparent reaction tube can be used, this being charged with HCl and O2 in the stoichiometric ratio of 4:1. The reaction mixture is irradiated in the reaction tube with short wavelength (<250 nm), coherent UV light with the aid of a pulsed excimer laser. The temperature of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com