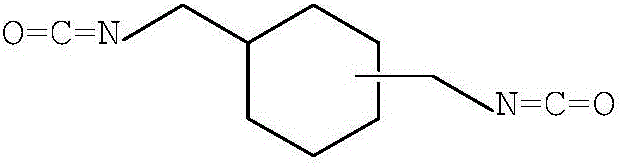

Preparation method of hydrogenated xylylene diisocynate

A technology for hydrogenating xylylene diisocyanate and cyclohexyldimethylamine, which is applied in the preparation of isocyanic acid derivatives, organic compounds, chemical instruments and methods, etc., can solve the problems of unindustrialization, severe amine coating, Solvent problems such as large amount, to achieve stable quality, improved dispersion and fluidity, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of hydrogenated xylylene diisocyanate of the present invention, comprises the following steps:

[0037] (1) Salt-forming reaction: At room temperature, first add 250 grams of toluene, 250 grams of concentrated hydrochloric acid with a concentration of 36%, and 30 grams of water into a 1L reactor, start the reactor to stir, and start to drop 1,3-cyclo Hexamethylene dimethylamine, keep the reaction temperature at 20°C, after 142 grams of 1,3-cyclohexanedimethylamine is added dropwise, keep it warm for 0.5h, then raise the temperature, reflux for dehydration, after dehydration is complete, the reaction solution enters the filter device and filters , to obtain the amine salt, the mother liquor is used mechanically, the amine salt is transferred to a vacuum drying device, and dried to obtain a solid product of the amine salt;

[0038] (2) Photochemical reaction: transport the amine salt obtained above to a 2L reactor, add 1300 grams of xylene and 0.5 gra...

Embodiment 2

[0041] A preparation method of hydrogenated xylylene diisocyanate of the present invention, comprises the following steps:

[0042] (1) Salt-forming reaction: At room temperature, first add 250 grams of toluene, 250 grams of concentrated hydrochloric acid with a concentration of 36%, and 30 grams of water into a 1L reactor, start the reactor to stir, and start to drop 1,3-cyclo Hexamethylene dimethylamine, keep the reaction temperature at 20°C, wait until 142 grams of 1,3-cyclohexanedimethylamine is added dropwise, keep the temperature for 0.5h, then raise the temperature, reflux for dehydration, after the dehydration is complete, the reaction liquid enters the filter device, filters, The amine salt is obtained, the mother liquor is used mechanically, the amine salt is transferred to a vacuum drying device, and dried to obtain a solid product of the amine salt;

[0043] (2) Photochemical reaction: transport the amine salt obtained above to a 2L reactor, add 1300 g of chloroben...

Embodiment 3

[0046] A preparation method of hydrogenated xylylene diisocyanate of the present invention, comprises the following steps:

[0047] (1) Salt-forming reaction: At room temperature, first add 250 grams of toluene, 250 grams of concentrated hydrochloric acid with a concentration of 36%, and 30 grams of water into a 1L reactor, start the reactor to stir, and start to drop 1,3-cyclo Hexamethylene dimethylamine, keep the reaction temperature at 20°C, wait until 142 grams of 1,3-cyclohexanedimethylamine is added dropwise, keep the temperature for 0.5h, then raise the temperature, reflux for dehydration, after the dehydration is complete, the reaction liquid enters the filter device, filters, The amine salt is obtained, the mother liquor is used mechanically, the amine salt is transferred to a vacuum drying device, and dried to obtain a solid product of the amine salt;

[0048] (2) Photochemical reaction: transport the amine salt obtained above to a 2L reactor, add 1300 g of trichloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com