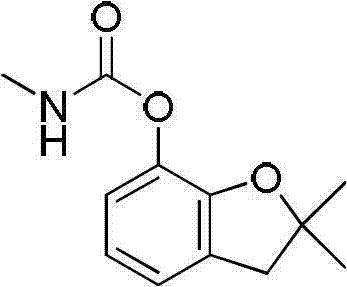

Production control method of 98 percent carbofuran

A production control method and content technology, applied in organic chemistry and other directions, can solve the problems of increasing recrystallization operations and costs, and achieve the effects of avoiding recrystallization operations, less solvent recovery, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

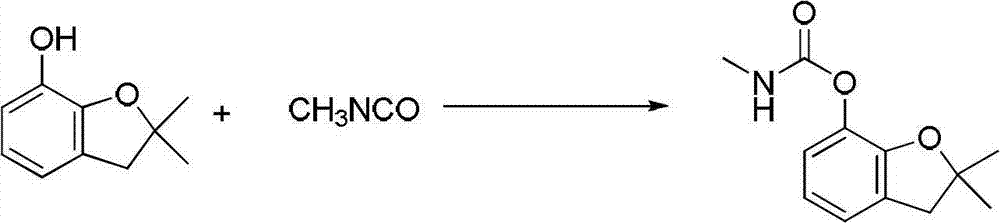

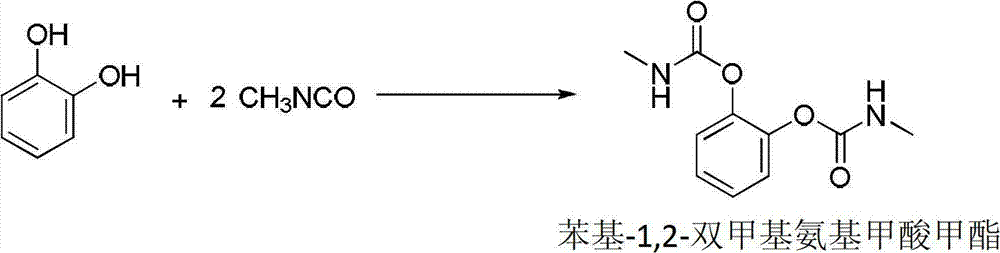

Method used

Image

Examples

Embodiment 1

[0028] Add 66g of industrial furanol (99%), 264g of 1,2-dichloroethane and 0.4g of triethylamine into a 500mL three-necked flask with cooling tube, dropping funnel, thermometer, and stirring, and heat to reflux temperature to start adding methyl Isocyanate, add 0.42mol methyl isocyanate within 1 hour, cool and crystallize at the end of the reaction, centrifuge filter and wash the filter cake with 20g of 1,2-dichloroethane, and the dry weight of the filter cake is 68.3g, analyzed by liquid chromatography external standard method The mass content of Weiwei is 98.9%.

[0029] The weight of the filtrate was 285.7g. Weighed out 10% of the filtrate and added fresh 1,2-dichloroethane of the same quality. The mixed filtrate was recycled as the solution for the next batch of reactions. The weighed 10% filtrate was distilled to recover 24.5g of 1,2-dichloroethane and 2.1g of white solid (carbofuran mass content 90.8%).

Embodiment 2

[0031] Applicable experiment: Add 66g of industrial product furanol (99%) and all the mother liquor of Example 1 into a 500mL three-neck flask with cooling tube, dropping funnel, thermometer, and stirring, and heat to reflux temperature to start adding methyl isocyanate dropwise. After adding 0.42 mol of methyl isocyanate, continue the reaction at 80°C for 1 hour. After the reaction is completed, cool and crystallize, filter the filter cake with 20 g of fresh 1,2-dichloroethane, dry the filter cake, and treat the filtrate according to the method of Example 1. , the experimental results are shown in Table 2.

[0032] Table 2 Applied experimental results

[0033] the batch

[0034] Apply 4 times

Embodiment 3

[0036] Add 66g of industrial furanol (99%), 132g of 1,2-dichloroethane and 0.4g of triethylamine into a 500mL three-necked flask with cooling tube, dropping funnel, thermometer, and stirring, and heat to reflux temperature to start adding methyl Isocyanate, add 0.42mol methyl isocyanate within 1 hour, cool and crystallize at the end of the reaction, centrifuge filter and wash the filter cake with 20g of 1,2-dichloroethane, and the dry weight of the filter cake is 78.8g, analyzed by liquid chromatography external standard method Granite mass content 98.4%.

[0037] The weight of the filtrate was 143.6g. Weighed out 15% of the filtrate and added fresh 1,2-dichloroethane of the same quality. The mixed filtrate was recycled as the solution for the next batch of reactions. The weighed 15% filtrate was distilled to recover 19.1g of 1,2-dichloroethane and 1.6g of white solid (mass content of carbofuran: 87.0%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com