Method for recycling chloroform in process of producing methyl isocyanate

A technology of methyl isocyanate and recovery method, which is applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, disproportionation separation/purification of halogenated hydrocarbons, etc., can solve the problems of waste of chloroform, increase of chloroform amount, etc., achieve cost saving, simple method, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

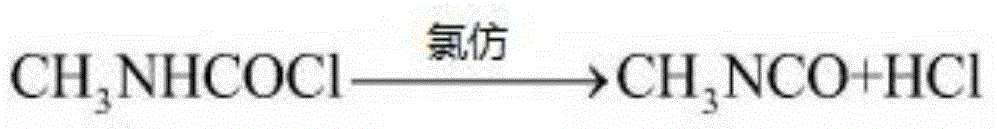

Image

Examples

Embodiment 1

[0012] A method for recovering chloroform in the process of producing methyl isocyanate. Methyl isocyanate is obtained by reacting phosgene with monomethylamine to generate methylcarbamoyl chloride, and then decomposing it with chloroform as a solvent. It is characterized in that: the exhaust gas after the decomposition is completed After being cooled to 30°C by the cooler, it enters the layerer. The chloroform and hydrochloric acid in the tail gas are layered in the layerer. The chloroform with a large specific gravity flows into the chloroform receiving tank to receive and circulate for the production of methyl isocyanate. Hydrochloric acid is recovered separately. When the chloroform in the chloroform receiving tank accumulates to 300-400L, the chloroform is discharged into the recovery bucket. Avoid chloroform entering the hydrochloric acid tank with hydrochloric acid. The recovery process of the tail gas is carried out under the condition of avoiding light.

Embodiment 2

[0014] A method for recovering chloroform in the process of producing methyl isocyanate. Methyl isocyanate is obtained by reacting phosgene with monomethylamine to generate methylcarbamoyl chloride, and then decomposing it with chloroform as a solvent. It is characterized in that: the exhaust gas after the decomposition is completed After being cooled to 40°C by the cooler, it enters the layerer. The chloroform and hydrochloric acid in the tail gas are layered in the layerer. The chloroform with a large specific gravity flows into the chloroform receiving tank to receive and circulate for the production of methyl isocyanate. Hydrochloric acid is recovered separately.

Embodiment 3

[0016] A method for recovering chloroform in the process of producing methyl isocyanate. Methyl isocyanate is obtained by reacting phosgene with monomethylamine to generate methylcarbamoyl chloride, and then decomposing it with chloroform as a solvent. It is characterized in that: the exhaust gas after the decomposition is completed After being cooled to 35°C by the cooler, it enters the layerer. The chloroform and hydrochloric acid in the tail gas are layered in the layerer. The chloroform with a large specific gravity flows into the chloroform receiving tank to receive and circulate for the production of methyl isocyanate. Hydrochloric acid is recovered separately.

[0017] Using the method of the present invention to treat tail gas in the process of producing methyl isocyanate and recycling chloroform can reduce the ton consumption of chloroform relative to methyl isocyanate products from 90Kg / t to 60Kg / t, greatly saving costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com