Preparation method of methyl isocyanate

A technology of methyl isocyanate and equipment, which is applied in the field of preparation of methyl isocyanate, can solve the problems of increasing three wastes, large investment in equipment, and long preparation process, so as to reduce energy consumption and the generation of by-products, reduce production costs, and improve single-pass production. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

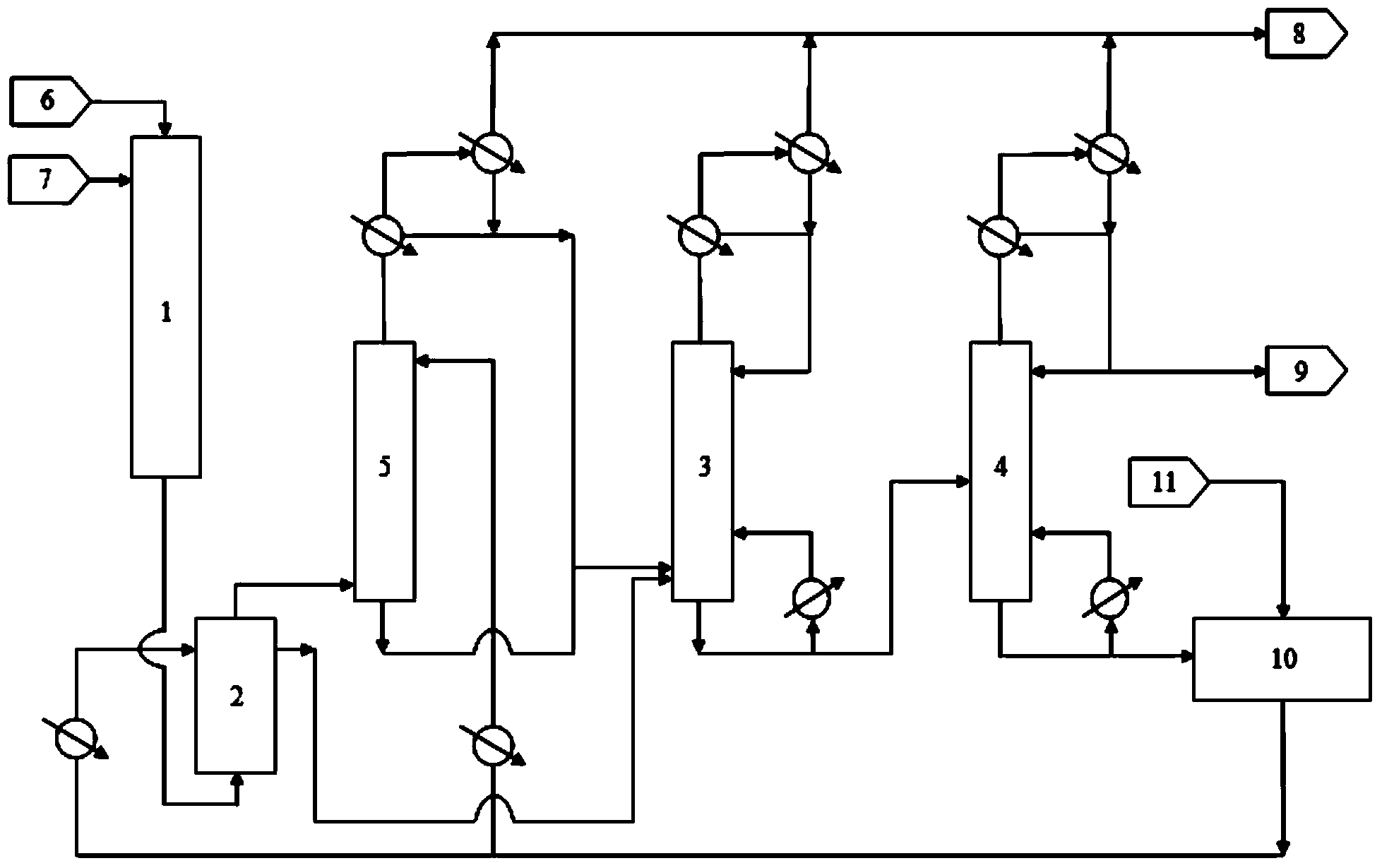

[0025] The invention provides a kind of preparation method of methyl isocyanate, comprising:

[0026] 1) reacting phosgene and methylamine at 300-400°C, keeping the obtained reaction product at 200-300°C and mixing it with the first organic solvent to obtain a solution containing methyl isocyanate and a first gas phase substance;

[0027] 2) removing the organic solvent in the solution containing methyl isocyanate to obtain methyl isocyanate.

[0028] According to the present invention, the present invention first reacts phosgene and methylamine at 300-400° C., the molar ratio of said phosgene to said monomethylamine is (1.0-1.2): 1; the temperature of said reaction is preferably 350 ~380°C.

[0029] According to the present invention, the obtained reaction product is kept at 200-300°C and mixed with the first organic solvent to obtain a solution containing methyl isocyanate and the first gas-phase substance; the first organic solvent is benzene, toluene, chlorobenzene, di O...

Embodiment 1

[0049] Pass 5.94kg / hr of phosgene and 1.56kg / hr of monomethylamine into the tubular reactor, and carry out the reaction at 330°C. The obtained reaction product is controlled at 245°C and directly enters the tank containing chloroform from the bottom In the bubble tower with automatic chain control liquid level, the soluble methyl isocyanate is absorbed by chloroform, and the solution containing methyl isocyanate is sent to the de-lighting tower. The molar ratio of methyl isocyanate and chloroform in the bubble tower is 1 : 6, the operating temperature is 55°C. The gas at the top of the bubbling tower enters the absorption tower for absorption. The operating temperature of the absorption tower is 35°C. The solution containing methyl isocyanate is treated with phosgene removal in a stripping tower with automatic chain control of the liquid level in the tower kettle. The operating temperature of the tower kettle is 45°C. The gas at the top of the stripping tower is treated by the...

Embodiment 2

[0052] Pass 5.44kg / hr of phosgene and 1.56kg / hr of monomethylamine into the tubular reactor, and carry out the reaction at 350°C, and control the obtained reaction product at 260°C and directly enter the tank containing chloroform In the bubble tower with automatic chain control liquid level, the soluble methyl isocyanate is absorbed by chloroform, and the solution containing methyl isocyanate is sent to the de-lighting tower. The molar ratio of methyl isocyanate and chloroform in the bubble tower is 1 : 8, the operating temperature is 50°C. The gas at the top of the bubbling tower enters the absorption tower for absorption. The operating temperature of the absorption tower is 38°C. The solution containing methyl isocyanate is treated with phosgene removal in the delighting tower with automatic chain control of the liquid level in the tower kettle. The operating temperature of the tower kettle is 50°C. The gas at the top of the delightening tower is treated by the tower top co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com