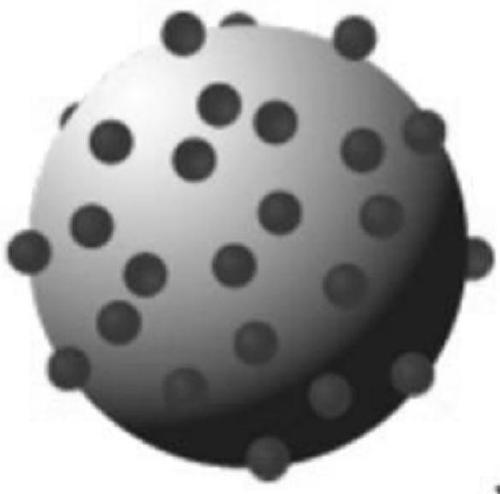

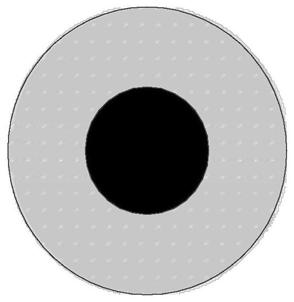

Yolk-eggshell SiO2-Al2O3 noble metal propane dehydrogenation catalyst and preparation method thereof

A technology of noble metal propane and dehydrogenation catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of short operation period and achieve enhanced physical strength , extend the operating cycle, and realize the effect of industrialized continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

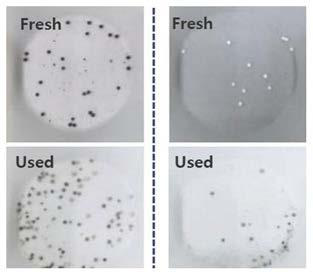

Examples

Embodiment 1

[0046] 1) Preparation of SiO 2 -Al 2 o 3 nanosphere

[0047] Mix acidic aluminum sulfate and basic potassium aluminate at a molar ratio of 7:3, then add desalted water to prepare a solution, heat to 55°C, and add ethyl orthosilicate three times while stirring, of which The molar ratio of ethyl ester to acidic aluminum sulfate is 1:3; then add sodium hydroxide to adjust the pH of the solution to 11, after the reaction is complete, filter with suction, and wash the obtained filter cake with desalinated water to wash excess sodium ions and potassium ions and sulfate until the washed solution shows a pH of 7. Add acetic acid to the filter cake, stir and add ammonia water ethanol solution to make the final slurry neutral, and filter to obtain SiO 2 -Al 2 o 3 filter cake, then dried to obtain SiO 2 -Al 2 o 3 nanomaterials, followed by SiO 2 -Al 2 o 3 A small amount of desalted water is added to the nanomaterials for gelatinization to make SiO 2 -Al 2 o 3 microspheres ...

Embodiment 2

[0060] 1) Preparation of SiO 2 -Al 2 o 3 Microspheres

[0061] Mix acidic aluminum sulfate and basic potassium aluminate according to the molar ratio of 7:3, then add desalted water to prepare a solution, heat to 60°C, and add ethyl orthosilicate three times under the condition of stirring, among which orthosilicate The molar ratio of ethyl ester to acidic aluminum sulfate is 1:2; then add sodium hydroxide to adjust the pH of the solution to 10, after the reaction is complete, filter with suction, and wash the obtained filter cake with desalted water to wash excess sodium ions and potassium ions and sulfate until the washed solution shows a pH of 7. Add acetic acid to the filter cake, stir and add ammonia water ethanol solution to make the final slurry neutral, and filter to obtain SiO 2 -Al 2 o 3 filter cake, then dried to obtain SiO 2 -Al 2 o 3 nanomaterials, followed by SiO 2 -Al 2 o 3 Add a small amount of desalted water to the nanomaterials for gelatinization,...

Embodiment 3

[0073] 1) Preparation of SiO 2 -Al 2 o 3 Microspheres

[0074] Mix acidic aluminum sulfate and basic potassium aluminate according to the molar ratio of 7:3, then add desalted water to prepare a solution, heat to 58°C, and add in three times while stirring, in which ethyl orthosilicate and acidic sulfuric acid The aluminum molar ratio is 1:2.6; Then add sodium hydroxide, adjust the pH of the solution to 10, after the reaction is complete, suction filter, the gained filter cake is washed with desalinated water, and excess sodium ions, potassium ions and sulfate radicals are washed until The eluted solution showed a pH of 7. Add acetic acid to the filter cake, and then add ammonia water and ethanol mixture under stirring conditions to make the final slurry neutral, and filter to obtain SiO 2 -Al 2 o 3 filter cake, then dried to obtain SiO 2 -Al 2 o 3 nanomaterials, followed by SiO 2 -Al 2 o 3 Add a small amount of desalted water to the nanomaterials for gelatinizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com