Patents

Literature

33results about How to "Avoid deep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

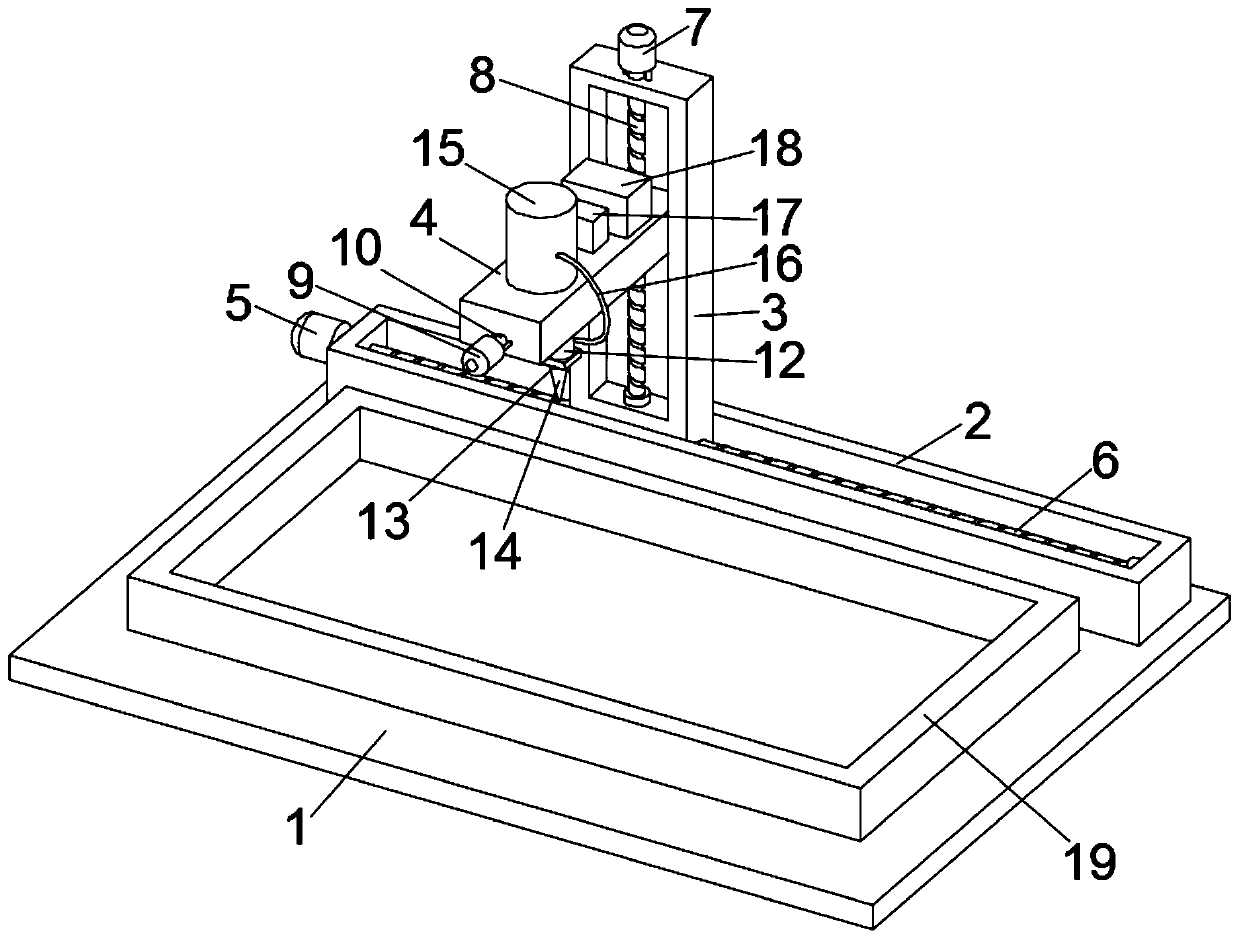

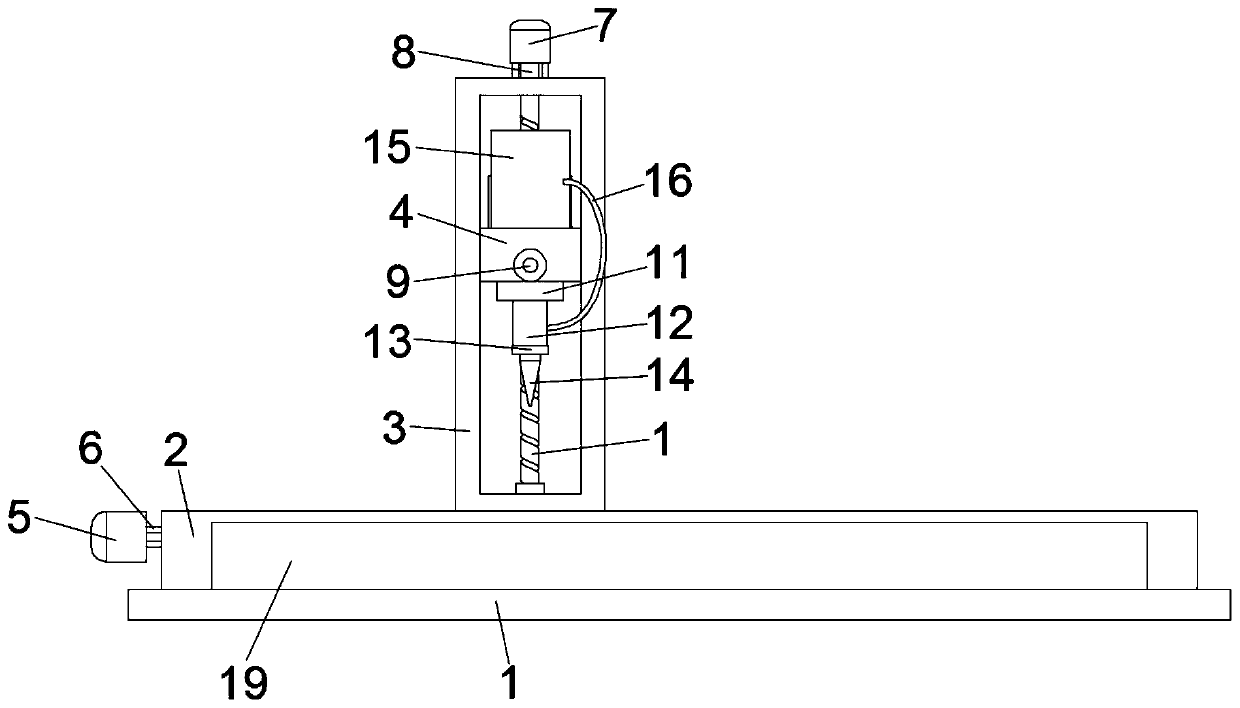

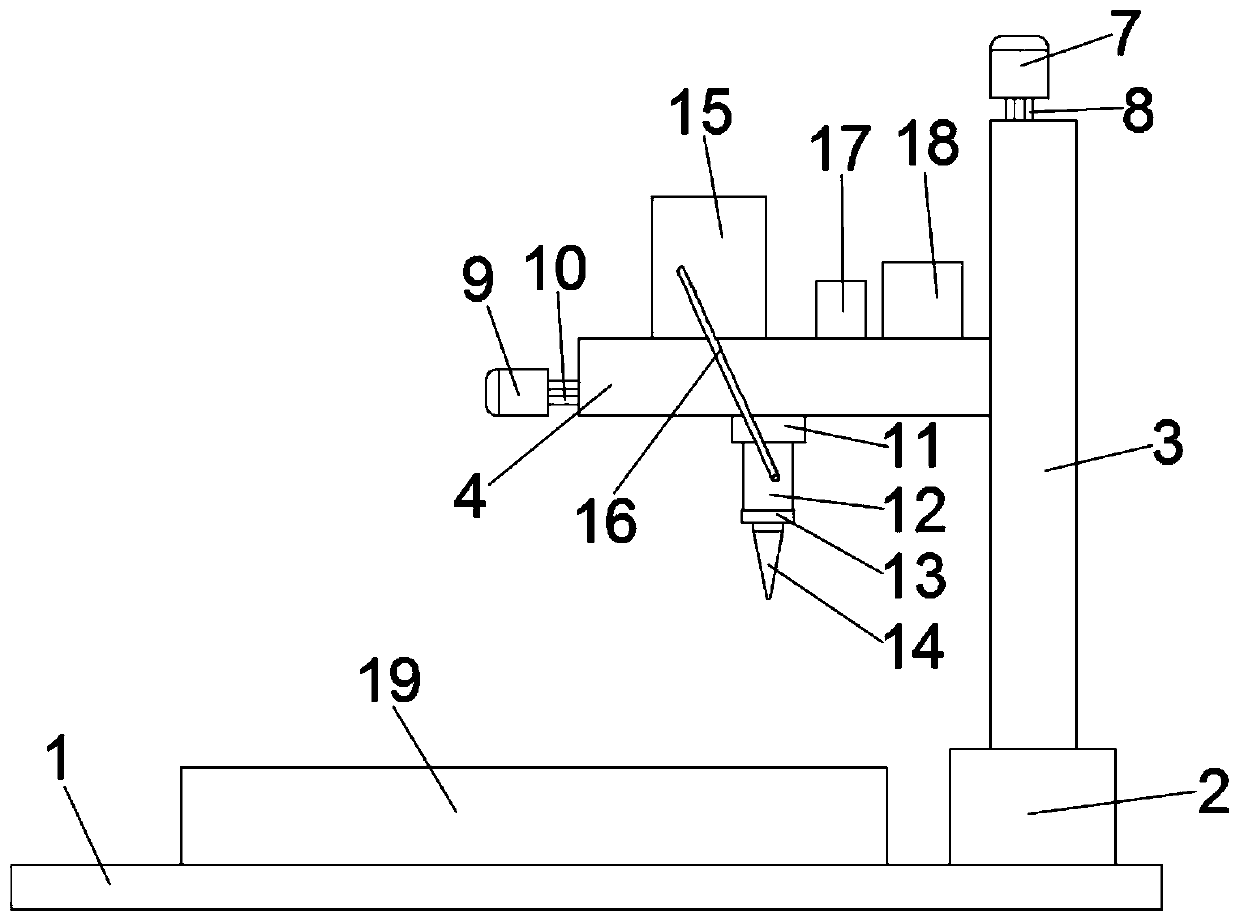

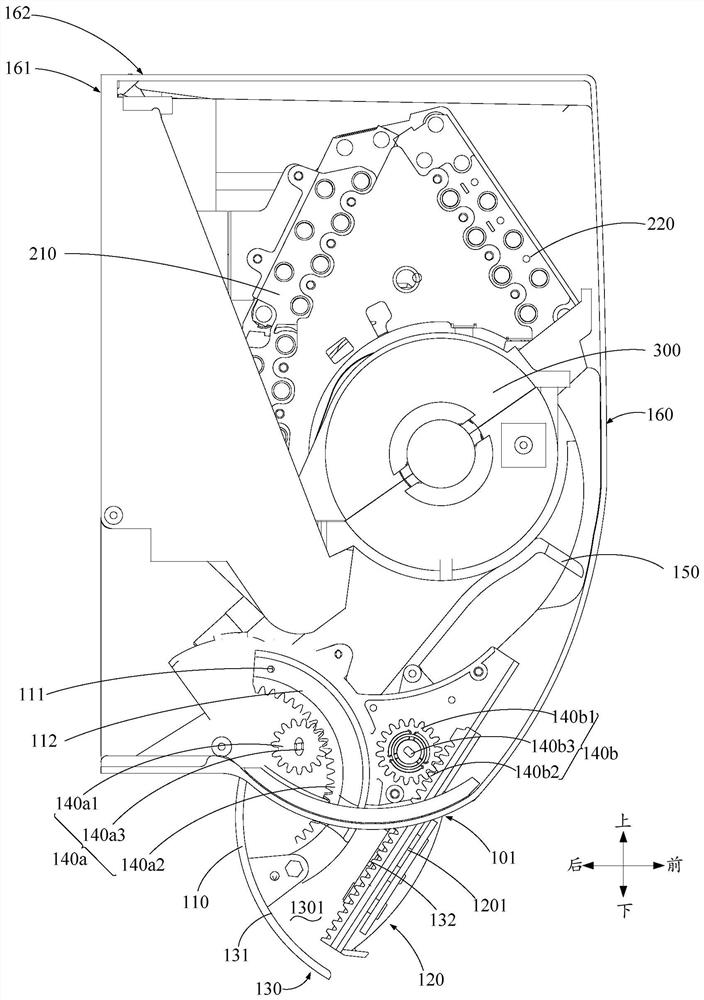

Automatic sealing dispensing machine for small liquid crystal display screens

PendingCN111013939AAvoid glue overflowAvoid the situationLiquid surface applicatorsCoatingsLiquid-crystal displayControl system

The invention discloses an automatic sealing dispensing machine for small liquid crystal display screens. The automatic sealing dispensing machine comprises a base. A transverse guide rail is horizontally mounted on the base. A lifting guide rail is vertically and movably embedded in the transverse guide rail. A longitudinal guide rail is movably embedded in the lifting guide rail. A mounting seatis movably embedded in the bottom of the longitudinal guide rail. A transverse drive mechanism, a lifting mechanism and a longitudinal drive mechanism are mounted on the transverse guide rail, the lifting guide rail and the longitudinal guide rail correspondingly. A dispensing machine is fixedly mounted at the bottom of the mounting seat, and a dispensing nozzle is arranged below the dispensing machine. A servo control system is arranged on the upper end face of the longitudinal guide rail. According to the dispensing machine for liquid crystal display screen sealing, three-dimensional multi-point automatic and precise dispensing of the dispensing machine is controlled through the servo control system, position adjustment is sensitive, the response speed is high, and the dispensing efficiency is high.

Owner:CHENZHOU HAILI MICROELECTRONICS TECH

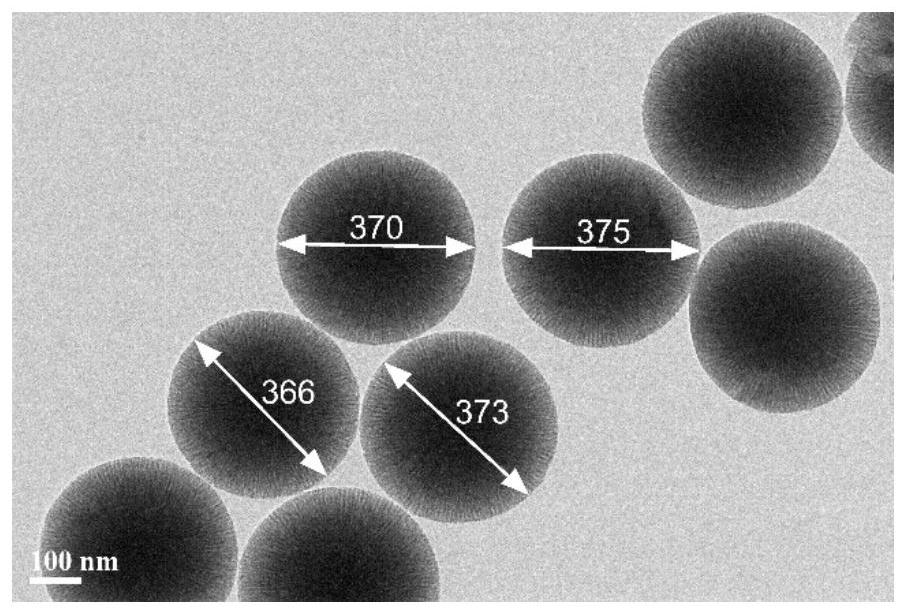

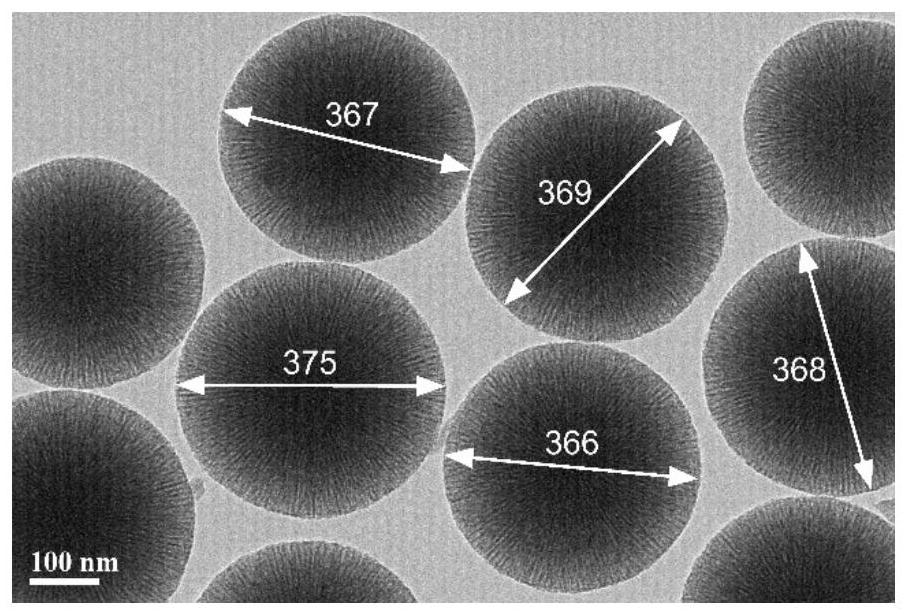

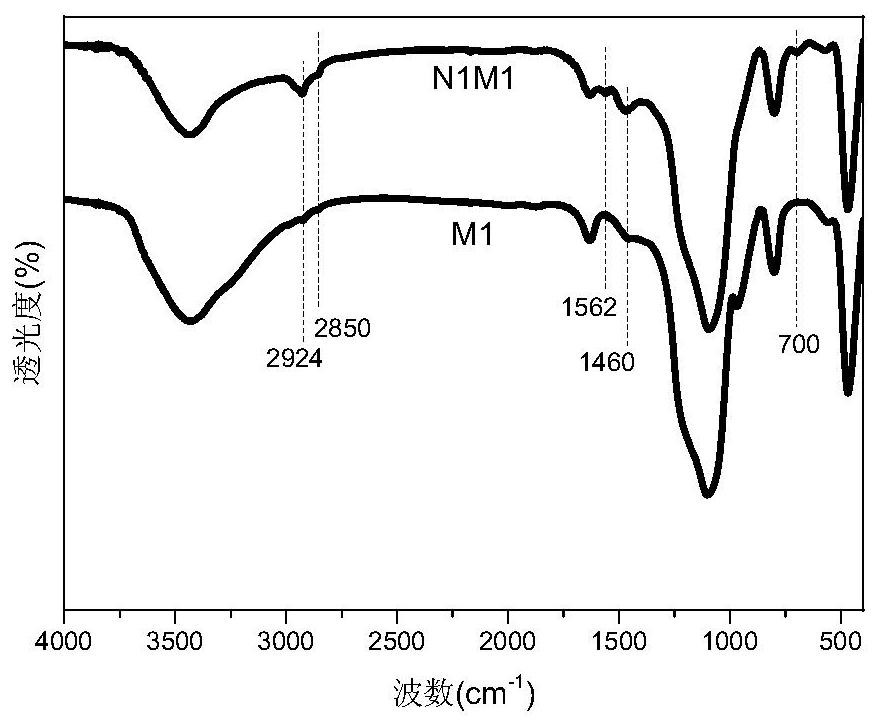

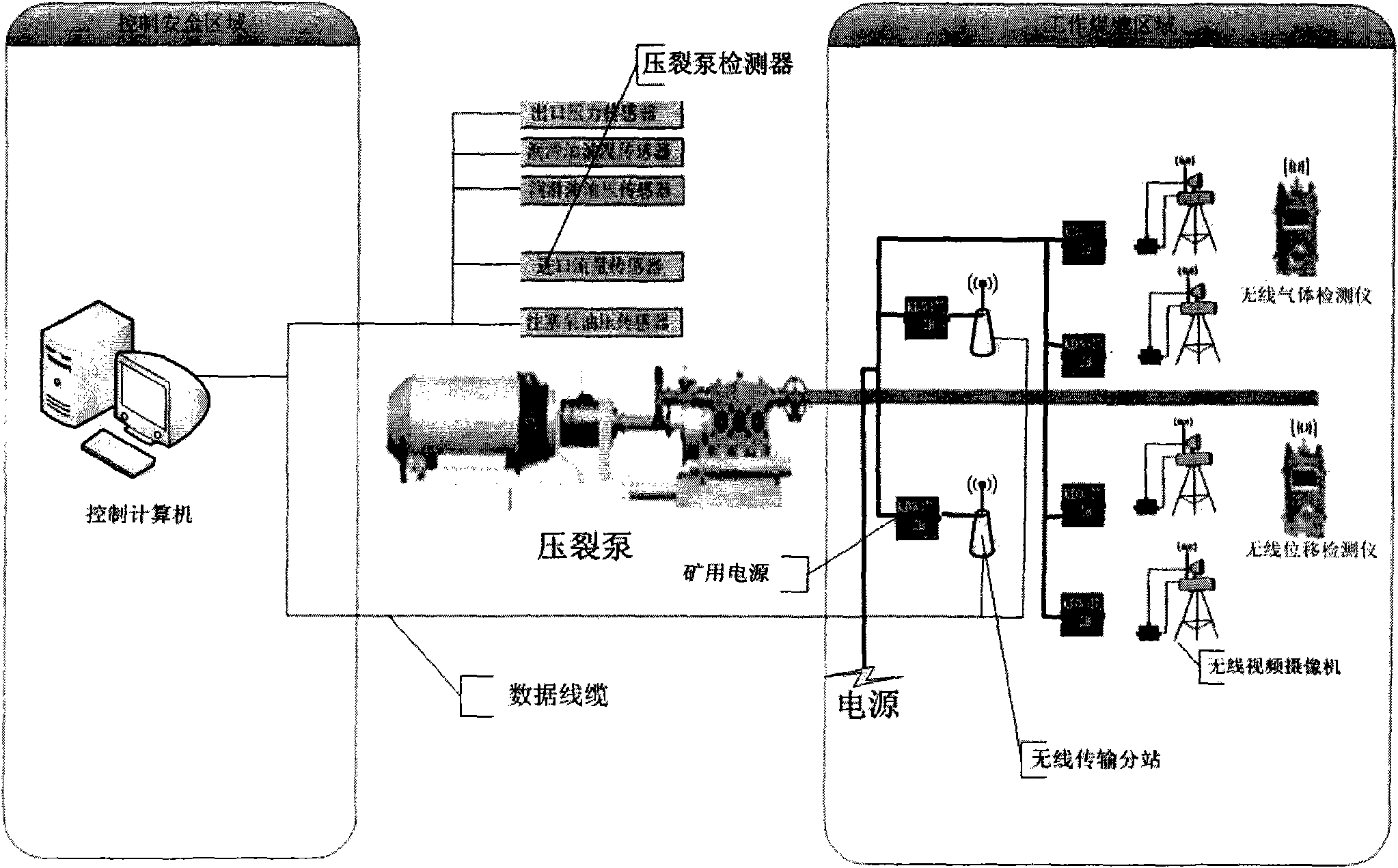

Preparation method of silver-silicon catalyst, silver-silicon catalyst and application of silver-silicon catalyst

PendingCN112387306AGood dispersionIncrease profitOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMicrosphere

The invention discloses a preparation method of a silver-silicon catalyst, the silver-silicon catalyst and application of the silver-silicon catalyst. According to the preparation method, mesoporous silica nano microspheres with large specific surface area, uniform pore size distribution and nanoscale center divergence short pore channels are used as carriers, a silane coupling agent is adopted tofunctionalize the amino groups on the surfaces of the mesoporous silica nano microspheres, then silver ions are connected to the functional groups of the pore channels under the action of coordination bonds, and finally the silver ions adsorbed in the pore channels are reduced into nano-silver particles in situ under the action of a reducing agent. Compared with a traditional catalyst taking silver as an active component, the catalyst prepared by the invention has the characteristics of remarkably reduced usage amount of noble metal silver, high dispersity, high activity and good stability, and shows excellent catalytic performance in preparation of methyl glycolate by hydrogenation of dimethyl oxalate, the conversion rate of dimethyl oxalate is greater than 99%, the selectivity of methylglycolate is not less than 94.9%, the yield is not less than 94.3%, and the method has a good industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

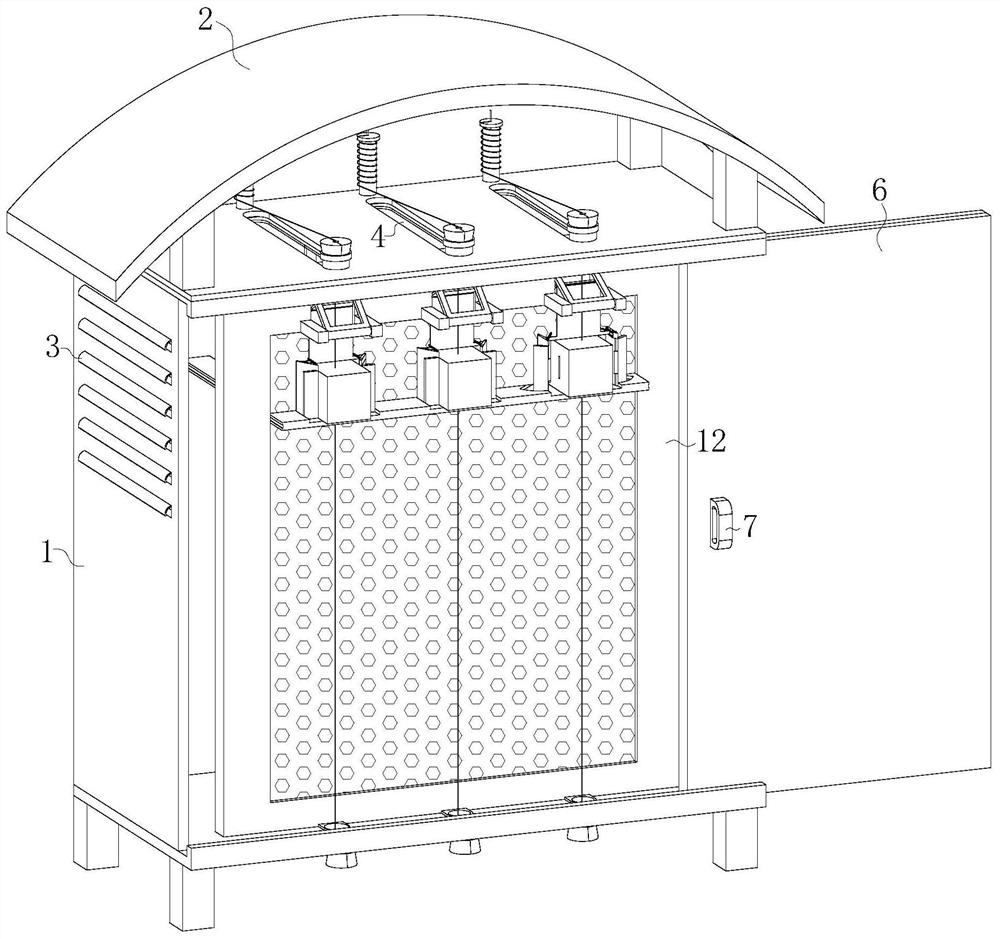

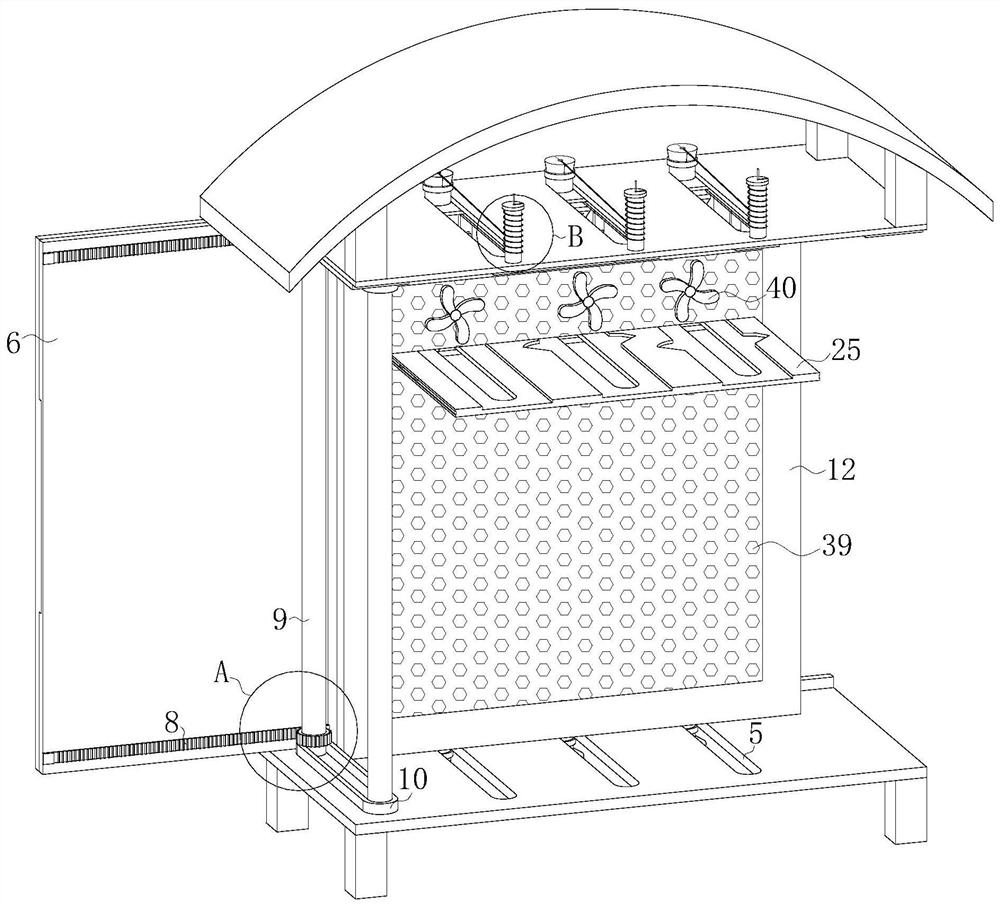

Efficient heat dissipation and cooling power distribution cabinet

InactiveCN112271583AAvoid deepImprove work efficiencySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsCooling powerMechanical engineering

The invention discloses an efficient heat dissipation and cooling power distribution cabinet in the technical field of power distribution cabinets, and the cabinet comprises a cabinet body, the top ofthe cabinet body is provided with an arc-shaped protection top, two sides of the cabinet body are provided with heat dissipation windows, and the top and bottom of the cabinet body are respectively provided with a wire inlet hole and a wire outlet hole. By arranging the mounting plate, the clamping plates, the T-shaped plate, the hollow plate, the pressing plate and the pressing block, a maintenance worker opens the cabinet door to enable the mounting plate to move outwards, when the mounting plate moves to different positions, the clamping plates on the two sides of different electrical components can be opened, the maintenance worker can directly take down the electrical components only at specific positions, maintenance workers do not need to use screwdrivers to disassemble electricalcomponents any more, time and labor are saved, the working efficiency is improved, the installation plate moves towards the cabinet door, the maintenance workers are prevented from going deep into thepower distribution cabinet with narrow space during maintenance, and maintenance is more convenient.

Owner:黄国兴

Anti-haze mask

The invention relates to an anti-haze mask, which is prepared from water, glycerol, butanediol, EDTA disodium, allantoin, sodium hyaluronate, dipotassium glycyrrhizinate, xanthan gum, carbomer, tocopherol acetic ester, lycine, collagen, pure plant anti-haze conditioning agents, pure plant anti-haze anti-sensitizers, anti-pollution algae and waterborne lubrajel oil. Various pure plant extracts are used; the use of chemical products is possibly reduced; the plant formula is safe and reliable; various nutrition substances such as vitamin are contained; the skin conditions can be fast improved; haze, dust and harmful gas are isolated the skin and the pores so as to have no harm on the skin; the skin aging is retarded; the skin vitality is enhanced.

Owner:杭州千岛湖蓝色天使实业有限公司

Anti-haze skin milk

InactiveCN107174547AReduce usageAvoid harmCosmetic preparationsToilet preparationsOctanoic AcidsTG - Triglyceride

The invention relates to anti-haze skin milk, which is prepared from water, glycerol, butanediol, DETA disodium, allantoin, sodium hyaluronate, dipotassium glycyrrhizinate, PEG-20 methyl glucoside sesquistearate, carbomer, tocopherol acetic ester, lycine, pure plant anti-haze conditioning agents, pure plant anti-haze anti-sensitizers, anti-pollution algae, trolamine, octanoic acid / decanoic acid triglyceride, isononyl isononanoate, cetostearyl alcohol ethylhexoate, evening primrose oil and dipotassium glycyrrhizinate. The skin milk ,contains various active ingredients of pure plant extracts; the use of chemical products is possibly reduced; the plant formula is safe and reliable; various nutrition substances such as vitamin are contained; the skin conditions can be fast improved; haze, dust and harmful gas are isolated from the skin and the pores so as to have no harm to the skin.

Owner:杭州千岛湖蓝色天使实业有限公司

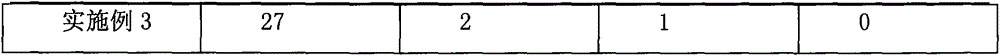

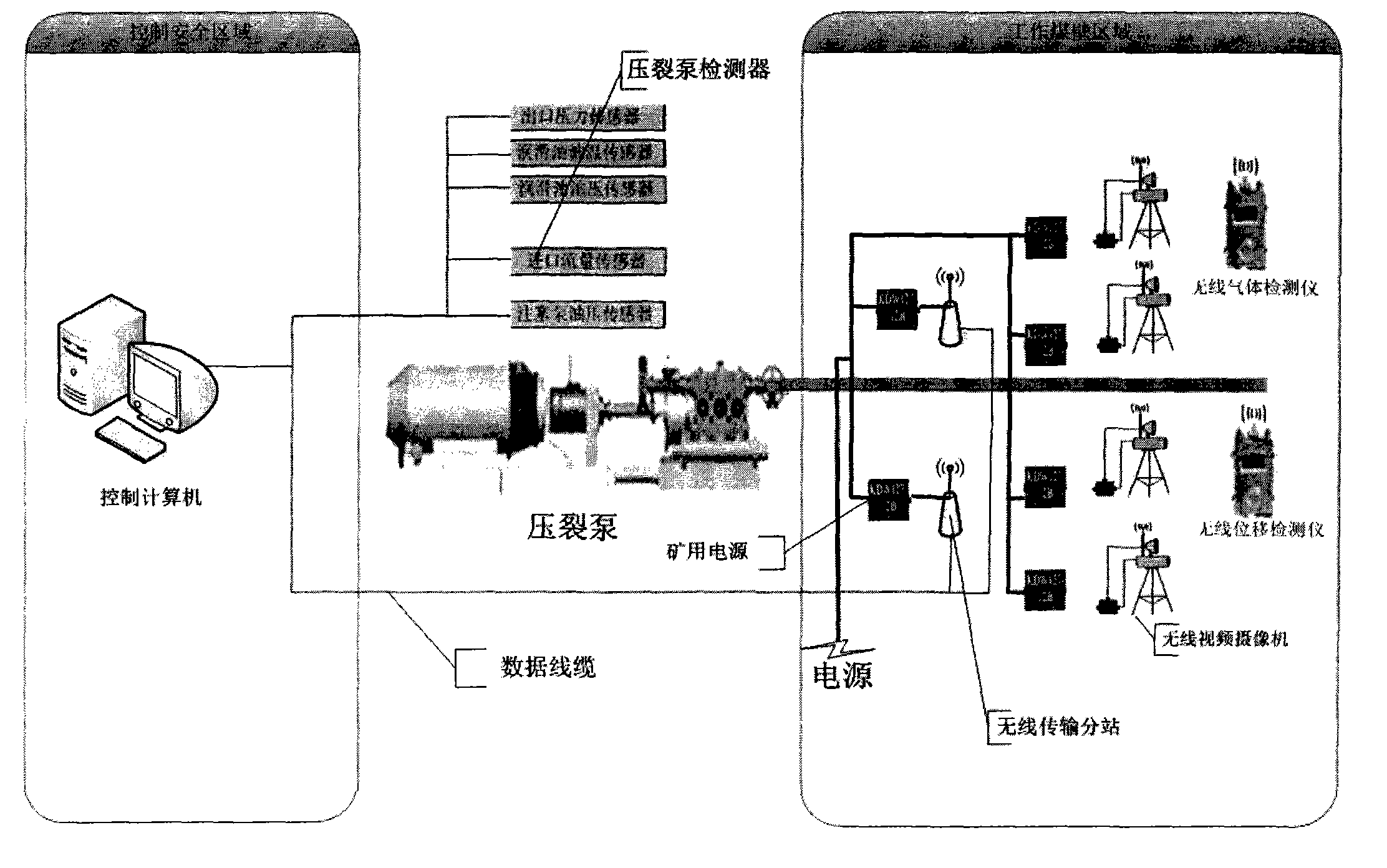

Fracturing detector under coal mine well

InactiveCN102135010ARealize wireless transmissionReduced installation effortMining devicesGas removalIntrinsic safetyReal-time data

The invention provides a fracturing detector under a coal mine well, belonging to an intrinsic safety type coal mine detector. A control computer is arranged at a safety area which is far away from a work coal wall at 1-2km. The control computer is connected with a wireless transmission substation; a wireless movement tester, a wireless gas tester and a wireless video camera are used for transmitting the collected detection data to the wireless transmission substation by a wireless signal, and the wireless transmission substation is used for transmitting the detection data to the control computer by a data cable and displaying the detection data; the control computer is connected with a fracturing pump detector by the data cable and to transmit the collected five real-time data of the fracturing pump to the control computer; and the operating personnel timely monitors the change condition of the work coal wall and the work state of fracturing equipment, and performs the necessary long-range control to the fracturing equipment.

Owner:NANJING BESTWAY AUTOMATION SYST +2

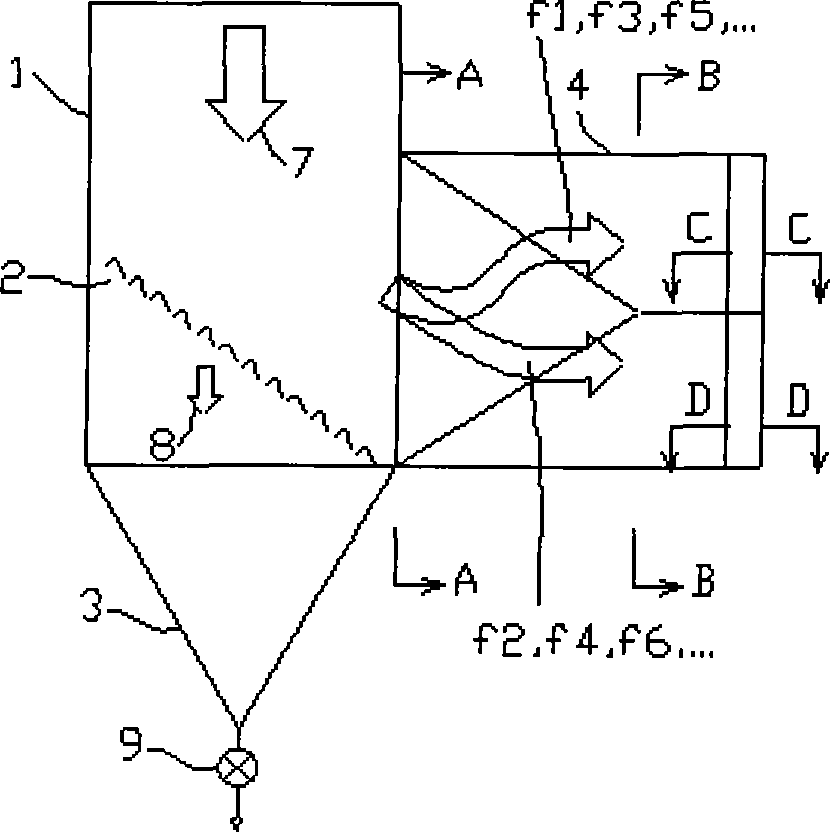

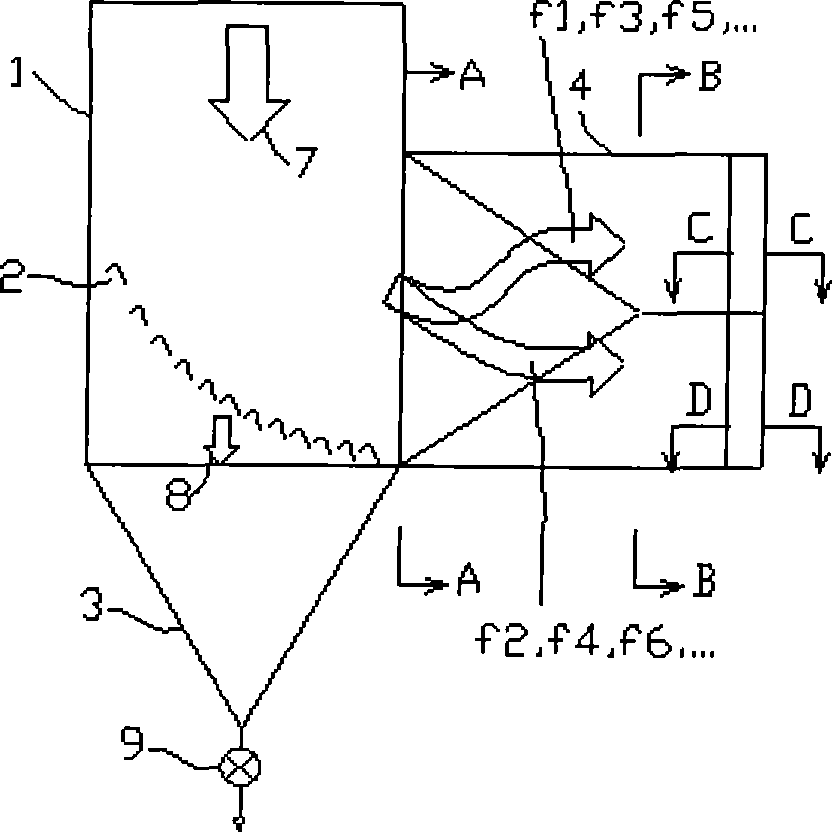

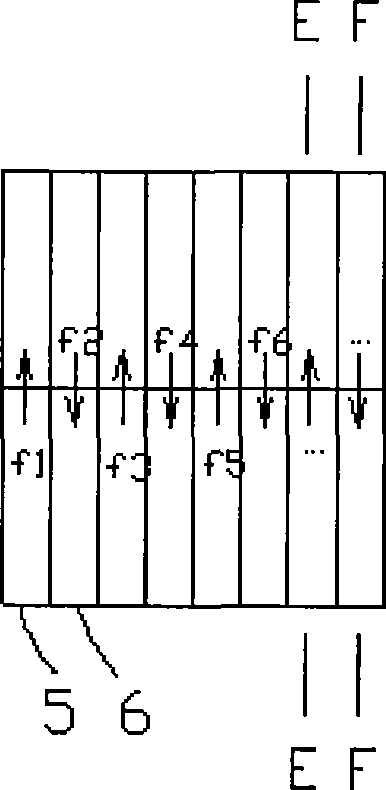

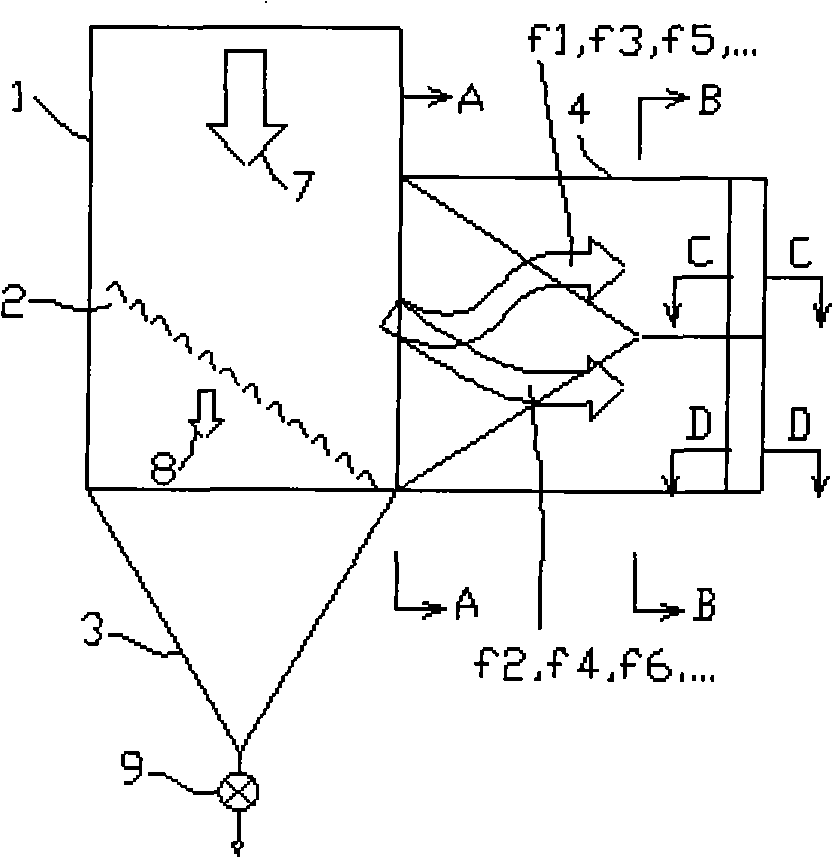

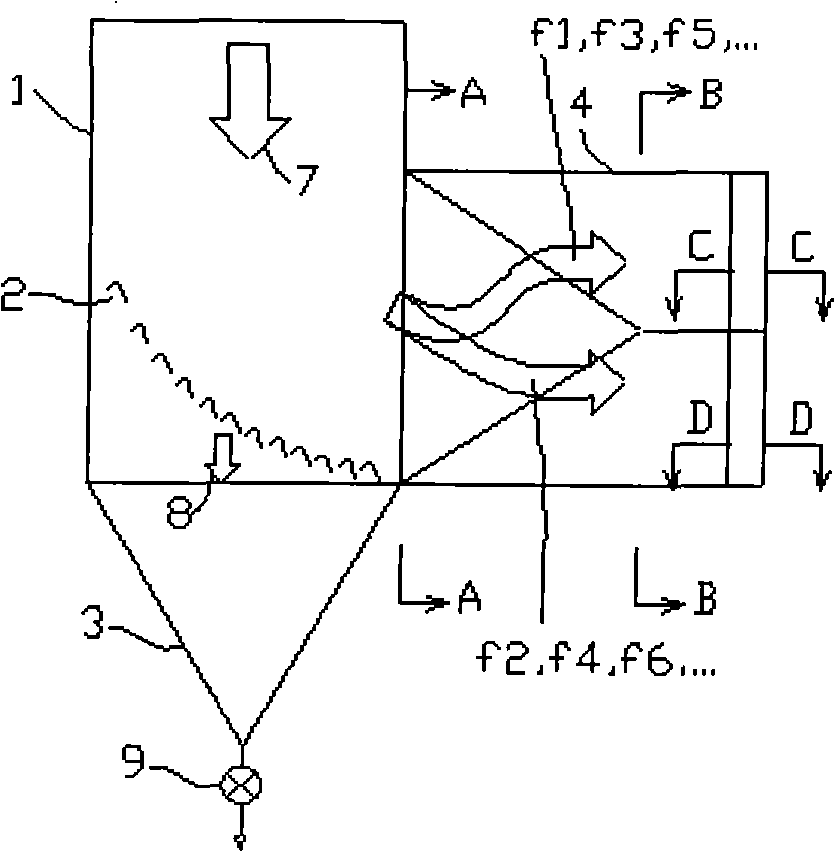

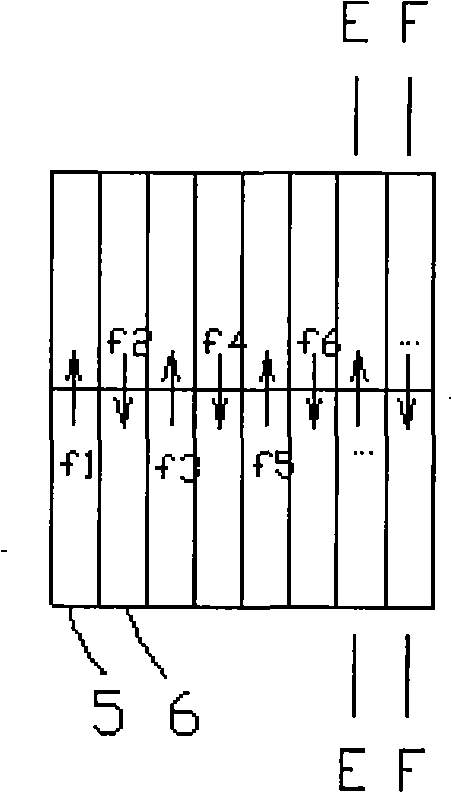

Zig air flue K-shaped flow equalizing apparatus with flyash separation

A K-type flow equalizing device with flying ash separated flashback air flue comprises a vertical air flue and a horizontal air flue, the lower end of the vertical air flue is provided with a flue-dust retainer and ash discharge device, the position of the vertical air flue turning to the horizontal air flue is provided with a flue gas turning external coating surface composed of delta wing grilles, the adjacent clearance between two delta wing grilles is communicated with the flue-dust retainer, the entrance of the horizontal air flue is distributed transversely with ascending and descending small air flues, the sum of the entrance cross sections of the ascending and the descending small air flues is equal to section area of the horizontal air flue, the ascending and the descending small air flues are alternately arranged inside the horizontal air flue and respectively introduces 50 0.000000lue gas to the upper semi-cross section of the horizontal air flue and 50 0.000000lue gas to the lower semi-cross section of the horizontal air flue. The flying ash described by the present invention is separated into the flue-dust retainer by delta wing grilles, which avoids the flue gas master stream from entering the flue-dust retainer and the flying ash from entering the flue gas by secondary entrainment, the ascending and descending small air flue alternate settings is alternately arranged in the horizontal air flue, the present invention realizes to make the severe oblique flow field distribution after acute steering in ultrashort distance evenly distribute in the whole air flue cross section rapidly.

Owner:XIAN THERMAL POWER RES INST CO LTD

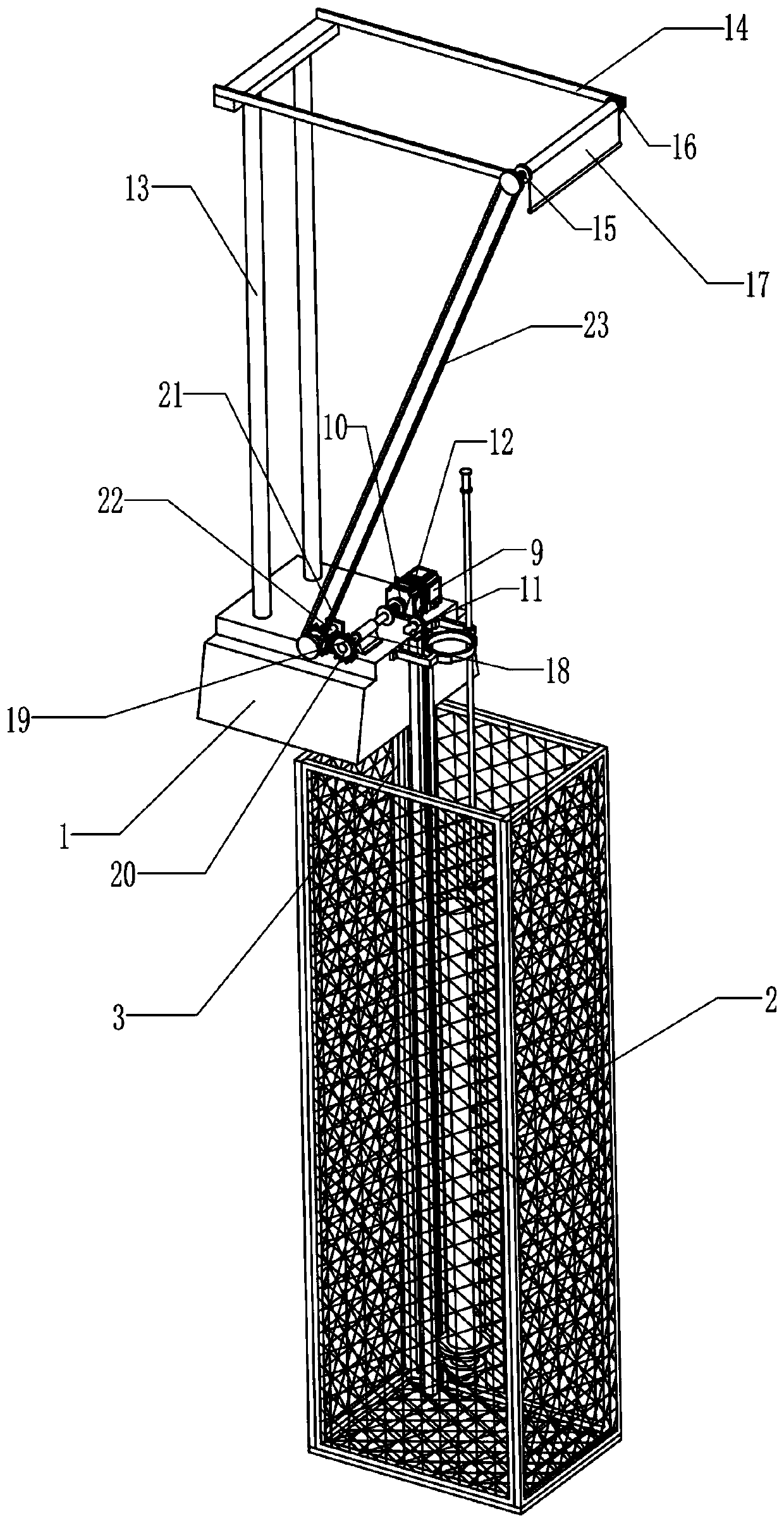

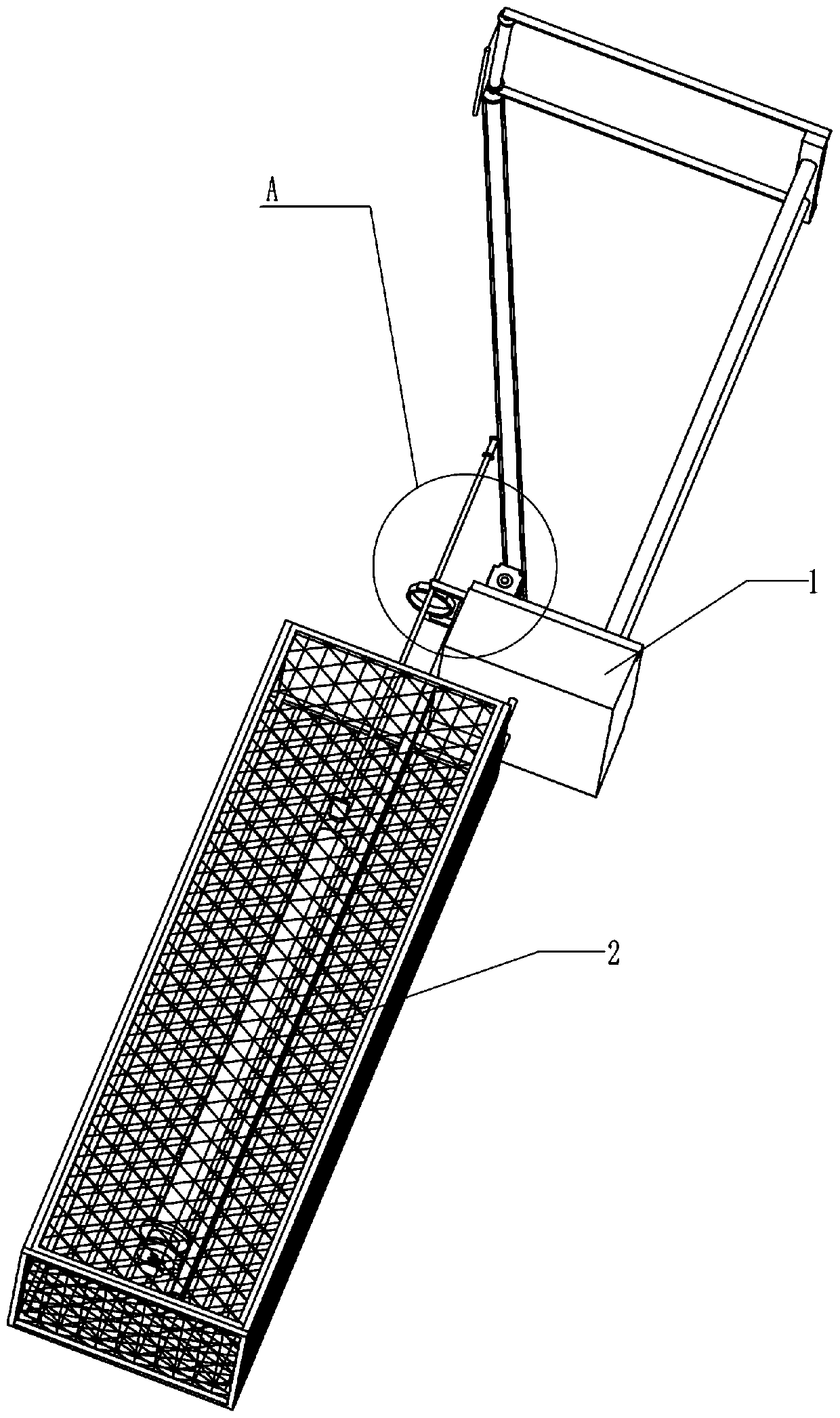

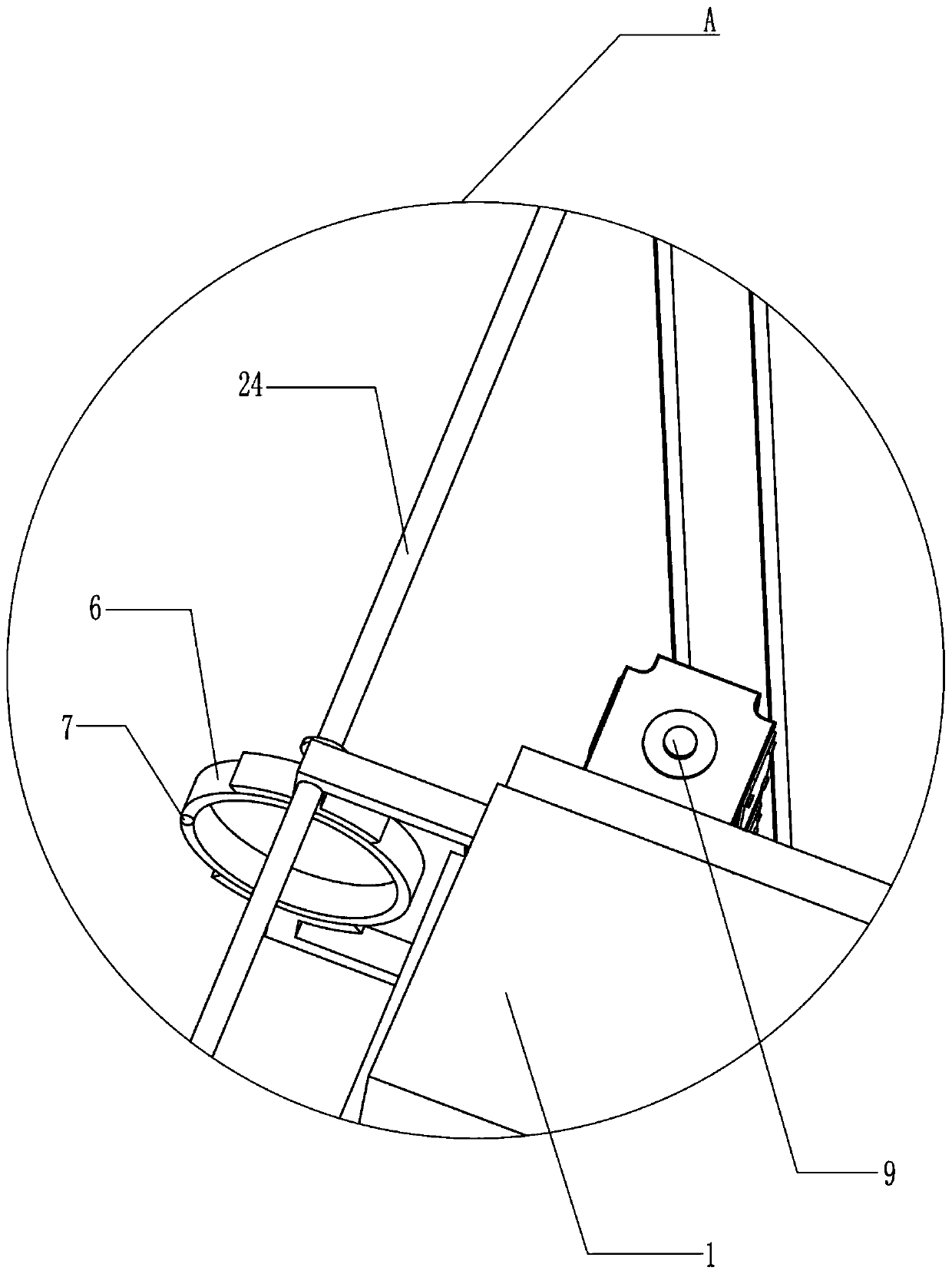

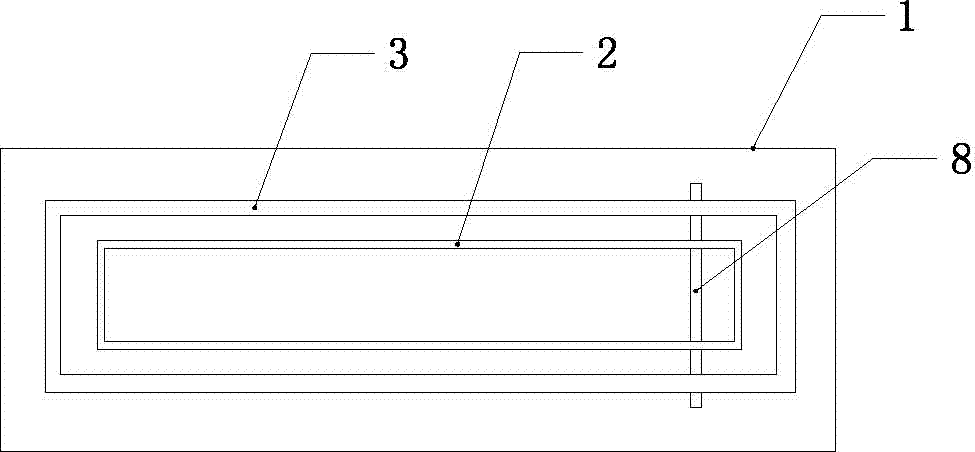

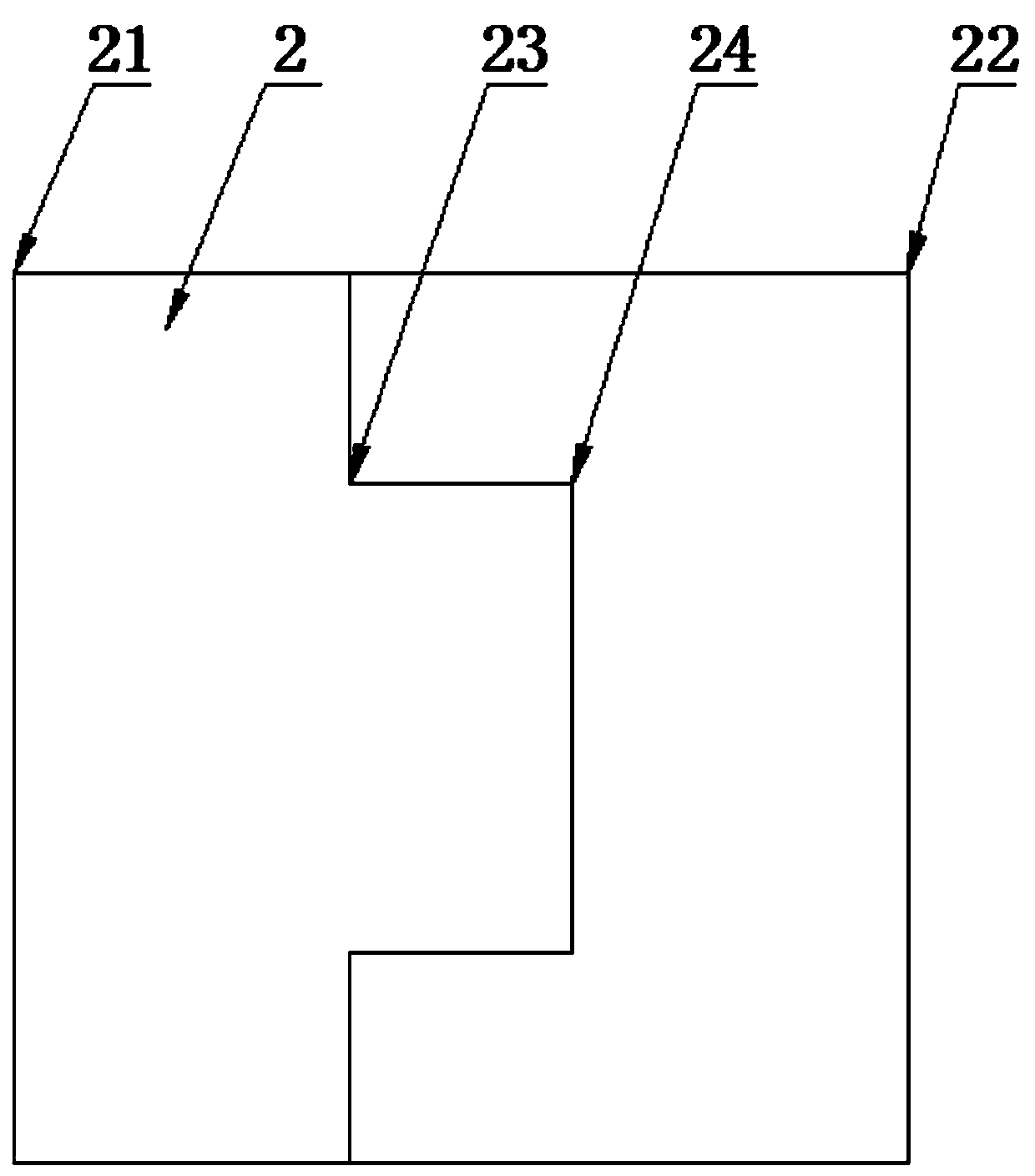

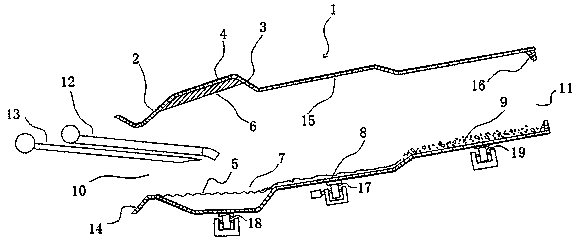

Water body stratified sampling equipment for environmental monitoring

ActiveCN111474010AImplement the sampling operationEasy to understandGeneral water supply conservationWithdrawing sample devicesStratified samplingMonitoring data

The invention relates to the technical field of environmental monitoring, in particular to water body stratified sampling equipment for environmental monitoring, and aims to provide the water body stratified sampling equipment for environmental monitoring, which can realize sampling investigation on water bodies with different depths, enables water body environmental monitoring data to be more representative and is convenient to use. According to the technical scheme, the water body stratified sampling equipment for environmental monitoring comprises a mounting base, an isolation net frame, aguide rail, a stratified liquid taking device, a liquid discharging device and the like. The isolation net frame is installed on one side face of the mounting base, the guide rail is fixedly installedon one side face of the upper portion of the installation base, the stratified liquid taking device is arranged on the guide rail, and the liquid discharging device is arranged in the stratified liquid taking device. Water samples entering the long cylinder can be separated through the first separation plate so that sampling operation of water at different depths is realized, and researchers areenabled to know conditions of water at different depths conveniently.

Owner:南昌市华测检测认证有限公司

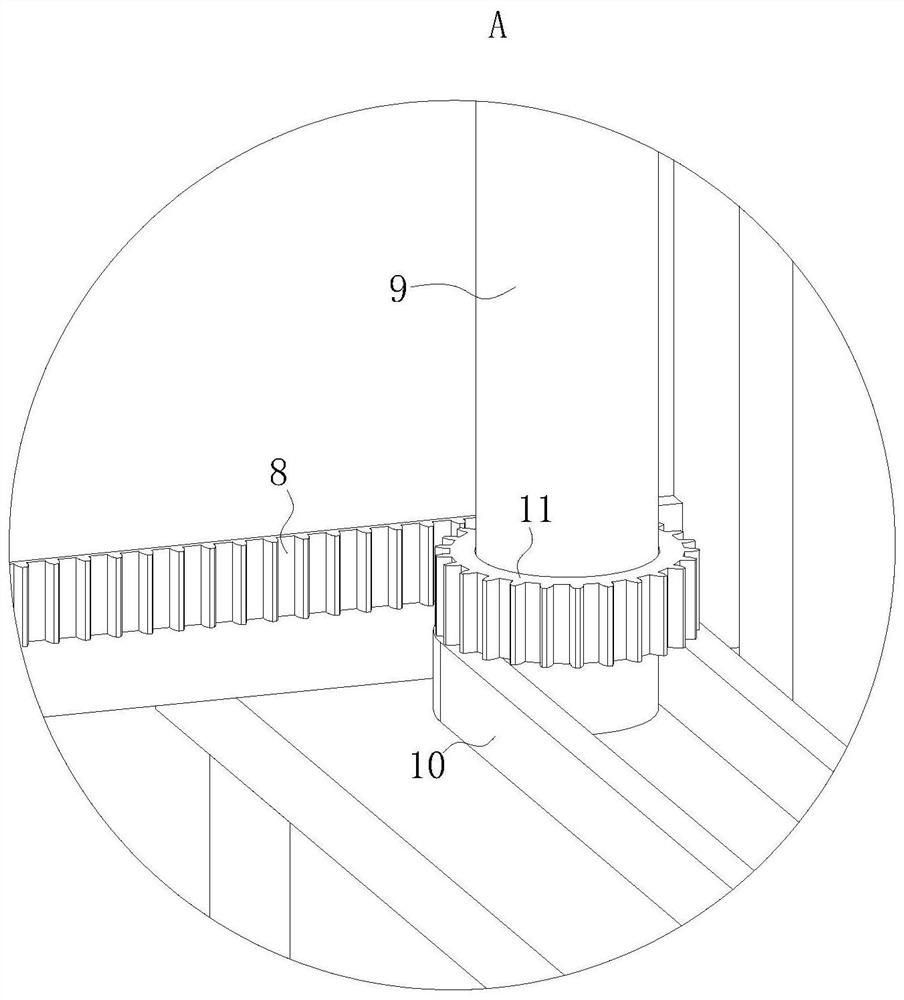

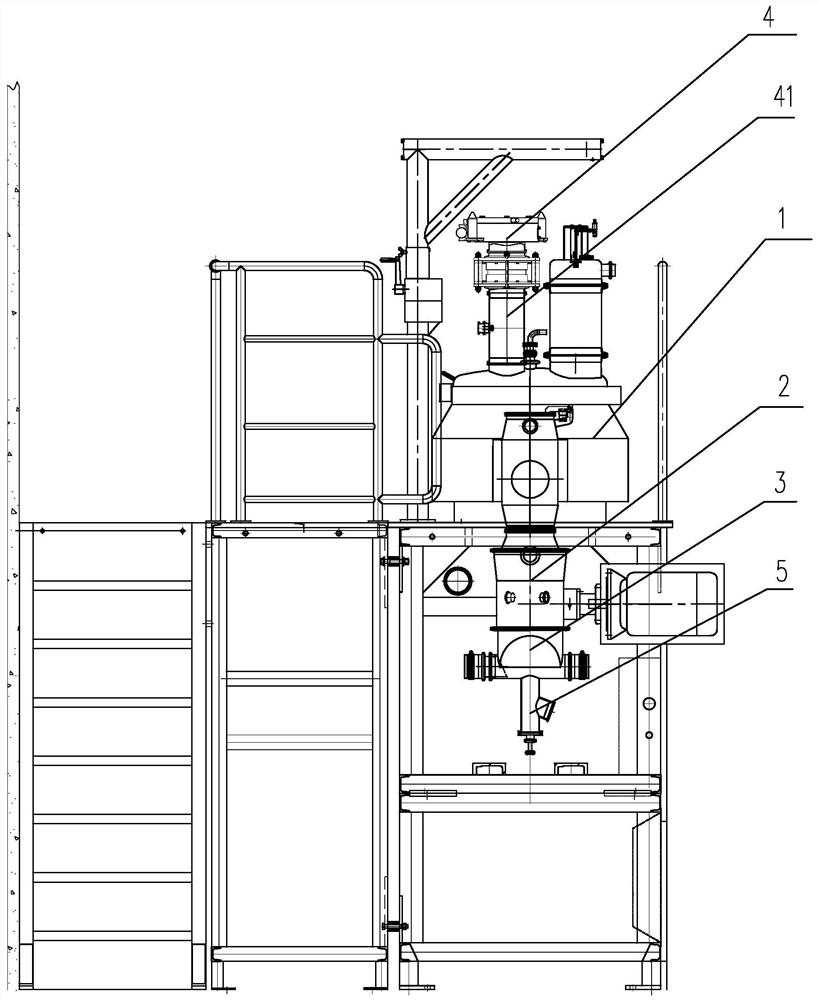

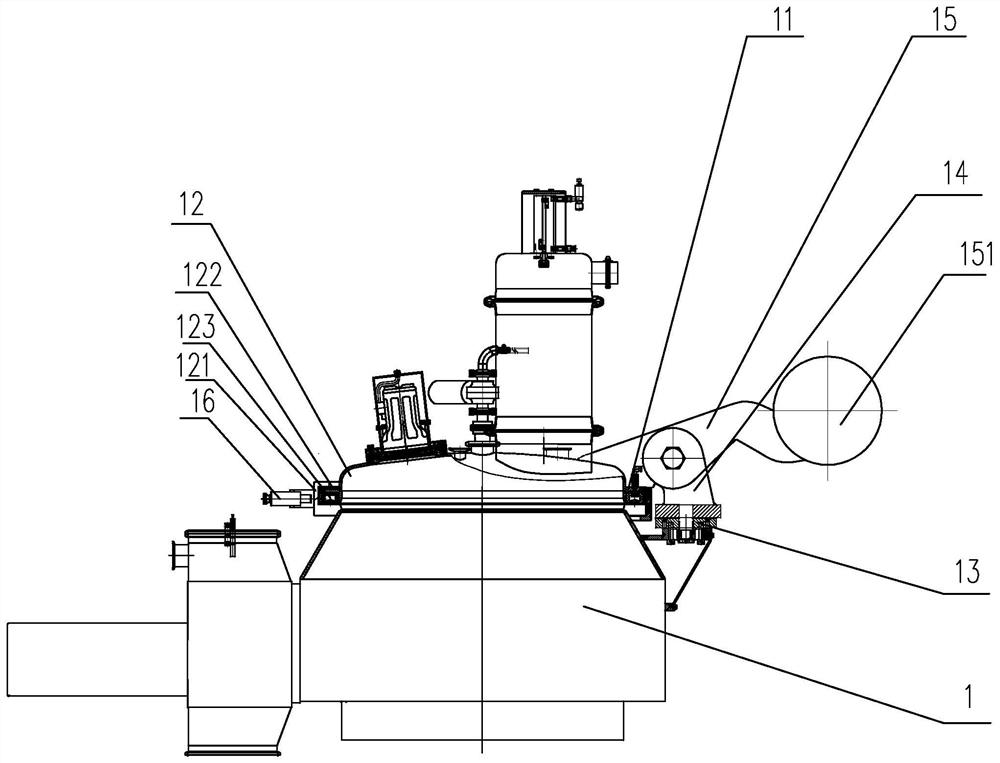

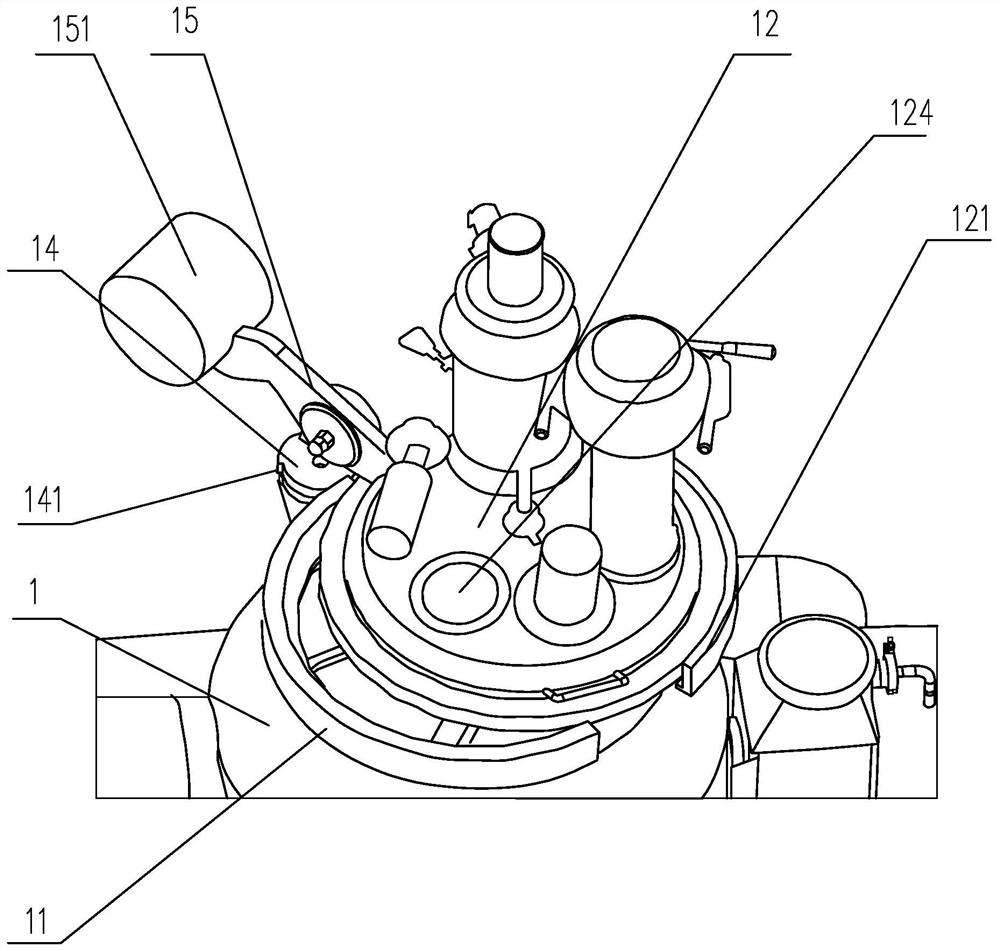

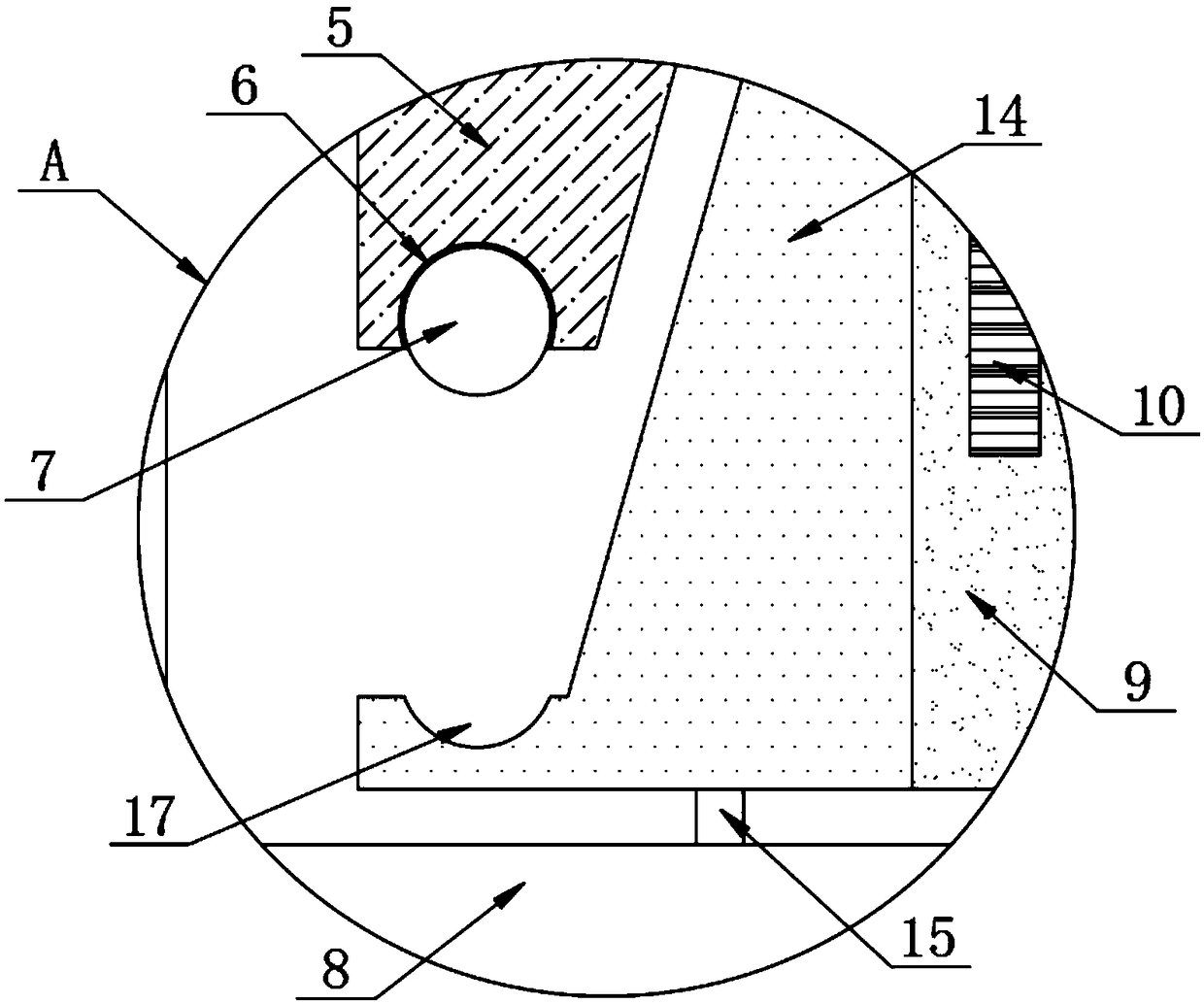

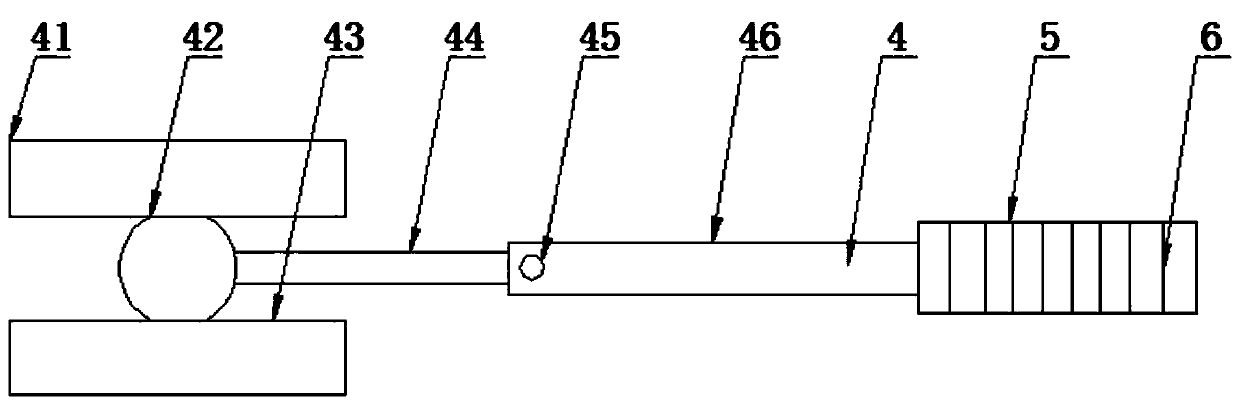

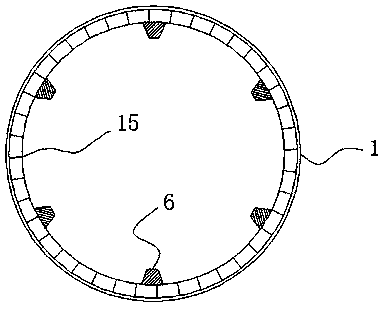

Whole-granule wet-process mixing granulator

PendingCN111701531AImprove cleanlinessPrevent leakageHollow article cleaningMaterial granulationStructural engineeringSewage

The invention discloses a whole-granule wet-process mixing granulator. The granulator comprises a material cylinder, a granulating machine and a discharging device, which are sequentially arranged from top to bottom. A cylinder cover is arranged on the material cylinder; the cylinder cover is connected with an alpha-beta valve; a rotating table is arranged on one side of the material cylinder; a connecting seat is rotationally arranged on the rotating table; and the cylinder cover is hinged to a connecting base through a swing rod. The cylinder cover is provided with a positioning check ring in the circumferential direction. An abutting check ring is arranged on the peripheral wall of the material cylinder; and a limiting piece is further arranged between the positioning check ring and theabutting check ring. A closed annular groove is formed in the cylinder cover; an inflatable sealing ring is arranged in the closed annular groove; an abutting table is formed at the position, corresponding to the closed annular groove, of the opening of the material cylinder, a first cleaner is arranged in a feeding pipe, a second cleaner is arranged in the material cylinder, a third cleaner is arranged in the granulating machine, a fourth cleaner is arranged in a discharging device, and a drainage device used for draining cleaning sewage is further arranged at the bottom of the discharging device. The whole granulator has a better sealing effect, is provided with an in-place cleaning system, and completely meets the requirements of OEB4.

Owner:ZHEJIANG CANAAN TECH

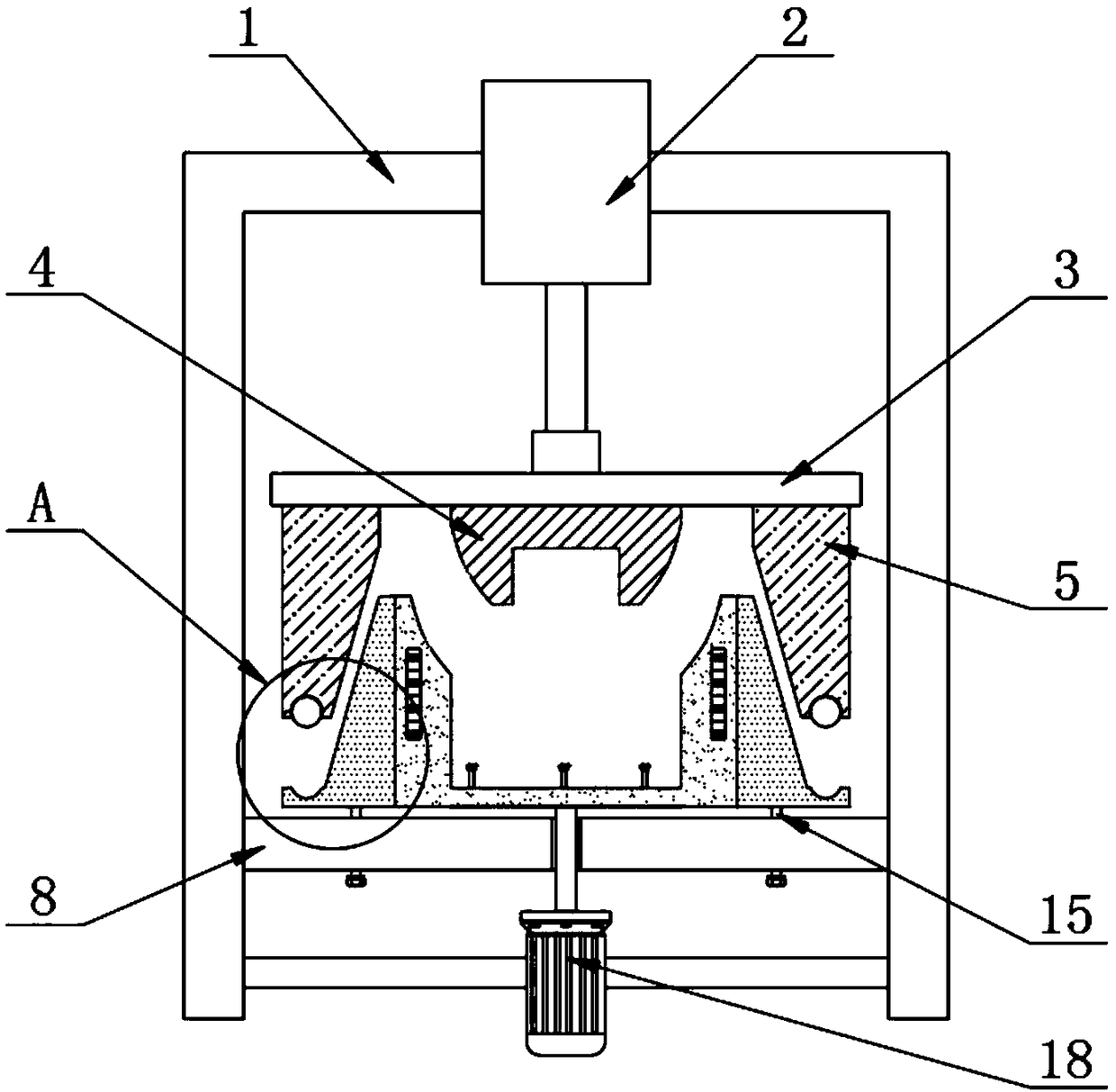

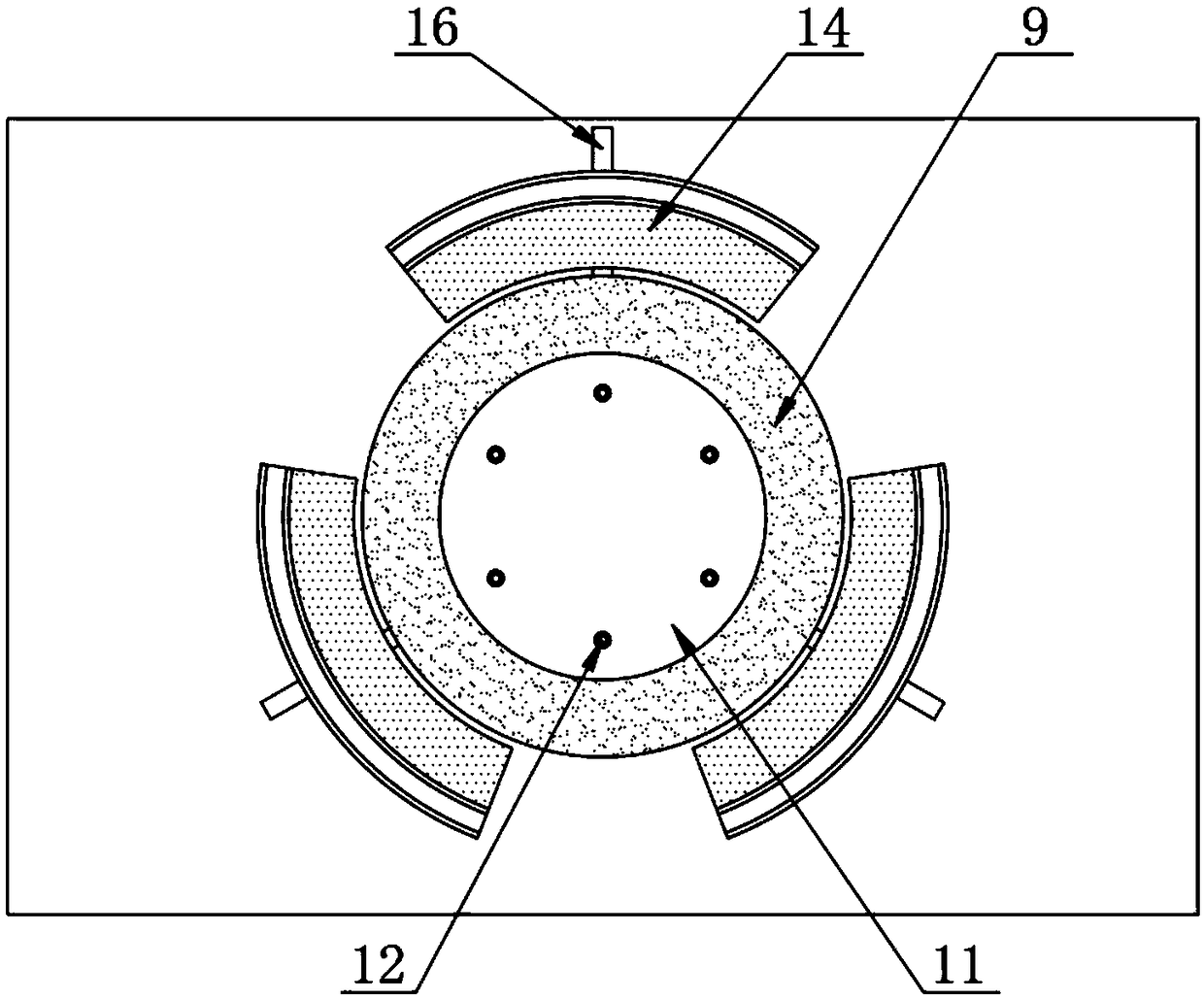

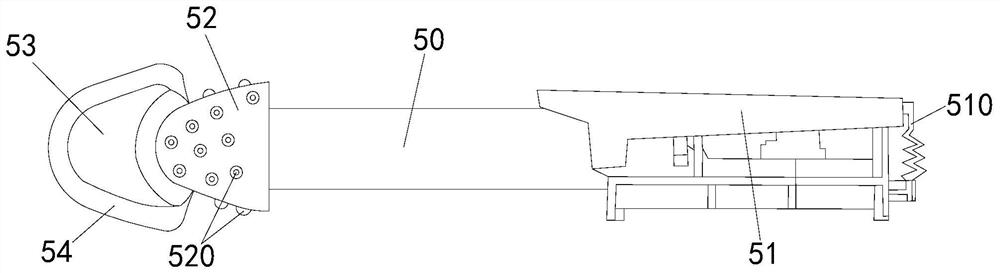

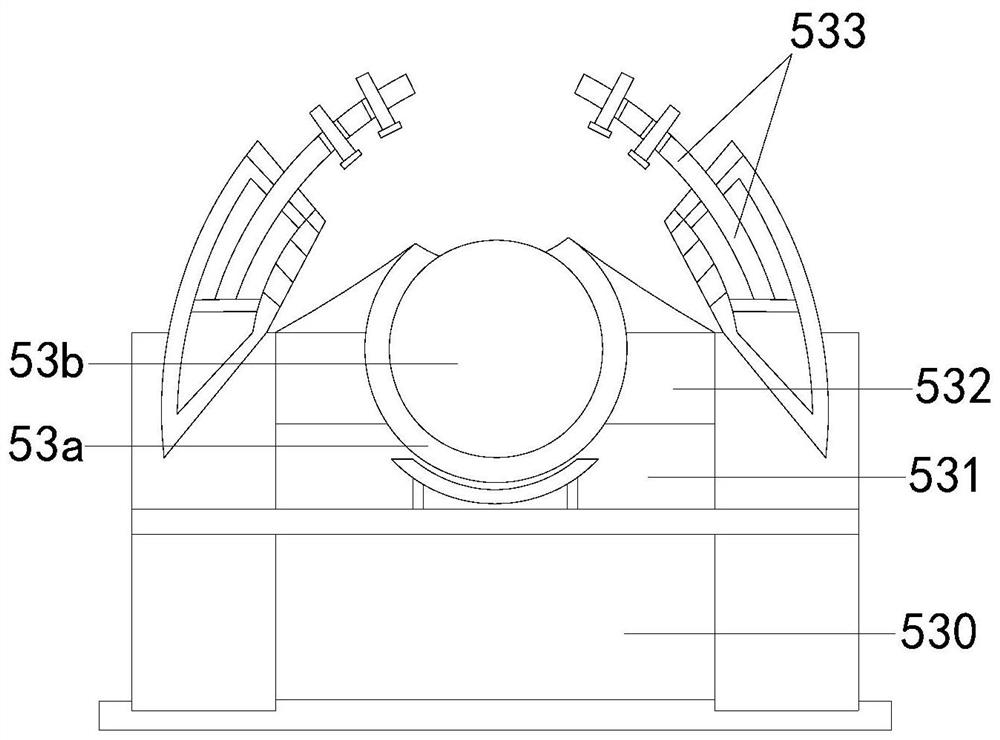

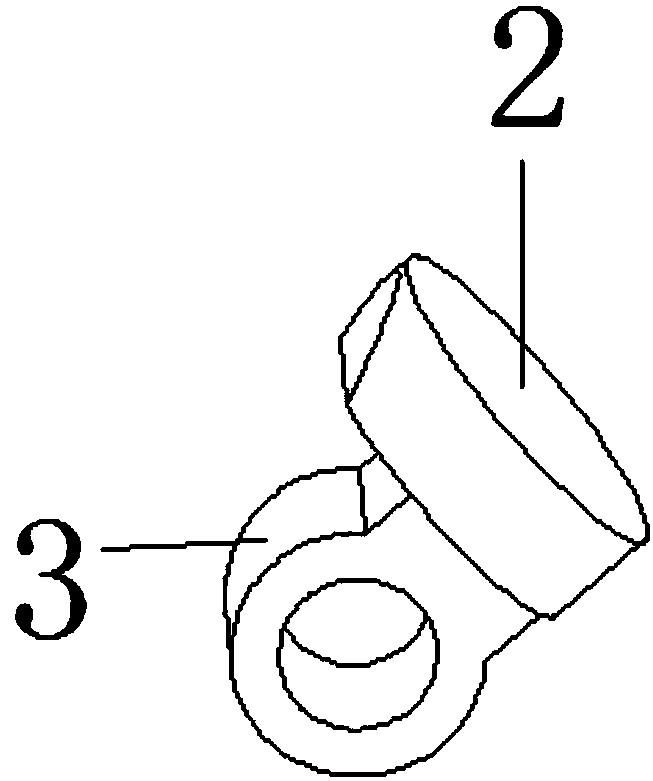

Heating and spinning flaring device

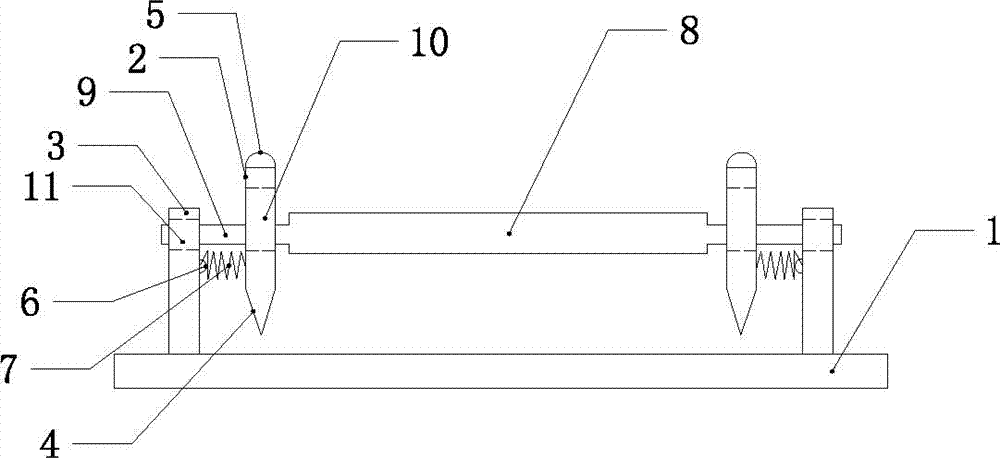

InactiveCN109365658AAdjust the flare sizeGuaranteed YieldShaping toolsMetal-working feeding devicesHydraulic cylinderEngineering

The invention discloses a heating and spinning flaring device which comprises a main body frame and a hydraulic cylinder, wherein the hydraulic cylinder is arranged at the top of the main body frame,and a mobile plate is arranged at one end of an output shaft of the hydraulic cylinder. A flaring die is arranged at the bottom of the mobile plate, and a positioning block is arranged at the outer part of the flaring die. A storage slot is formed in the bottom end of the positioning block, and a ball is arranged in the storage slot. A fixing plate is arranged at the bottom of the flaring die, anda mobile disc is arranged at the top of the fixing plate. A heating rod is arranged in the mobile disc, and a flaring die slot is formed in the mobile disc. A first fixed slot is arranged in the flaring die slot, and a thermal insulating layer is arranged on the outer wall of the mobile disc. According to the heating and spinning flaring device, the position of a positioning disc is adjusted by asecond fixed bolt, and the relative position of the positioning disc and the positioning block is adjusted by the second fixed bolt; the hydraulic cylinder works to drive the flaring die to flare a hub of a forklift truck through the mobile plate, and the inclined plane of the positioning block is limited by the inclined plane of the positioning disc; and therefore the effect of adjusting the size of flaring is achieved.

Owner:YUEXI SHENGHONG IND & TRADE

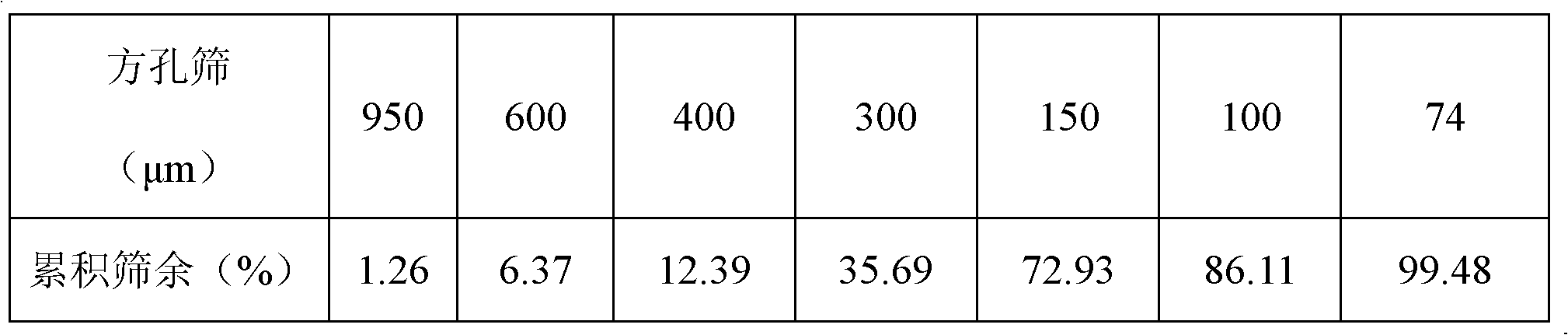

Environment-friendly recycled fine sand

ActiveCN103159421AImprove qualityEasy to useSolid waste managementNational standardMaterials science

The invention discloses an environment-friendly recycled fine sand, wherein the fine sand is a building waste recycled aggregate having a particle size of not less than 80 mumm and not greater than 1000 mum. The invention further discloses a preparation method and an application for the environment-friendly recycled fine sand disclosed by the invention. The environment-friendly recycled fine sand disclosed by the invention meets the related national standards, and is convenient to use; the needs of mechanically-jetted mortar, heat-insulating mortar, thin-type masonry mortar, aerated concrete and the like are met; and resource comprehensive utilization, fine utilization and high-added-value utilization are realized.

Owner:上海德滨环保科技有限公司

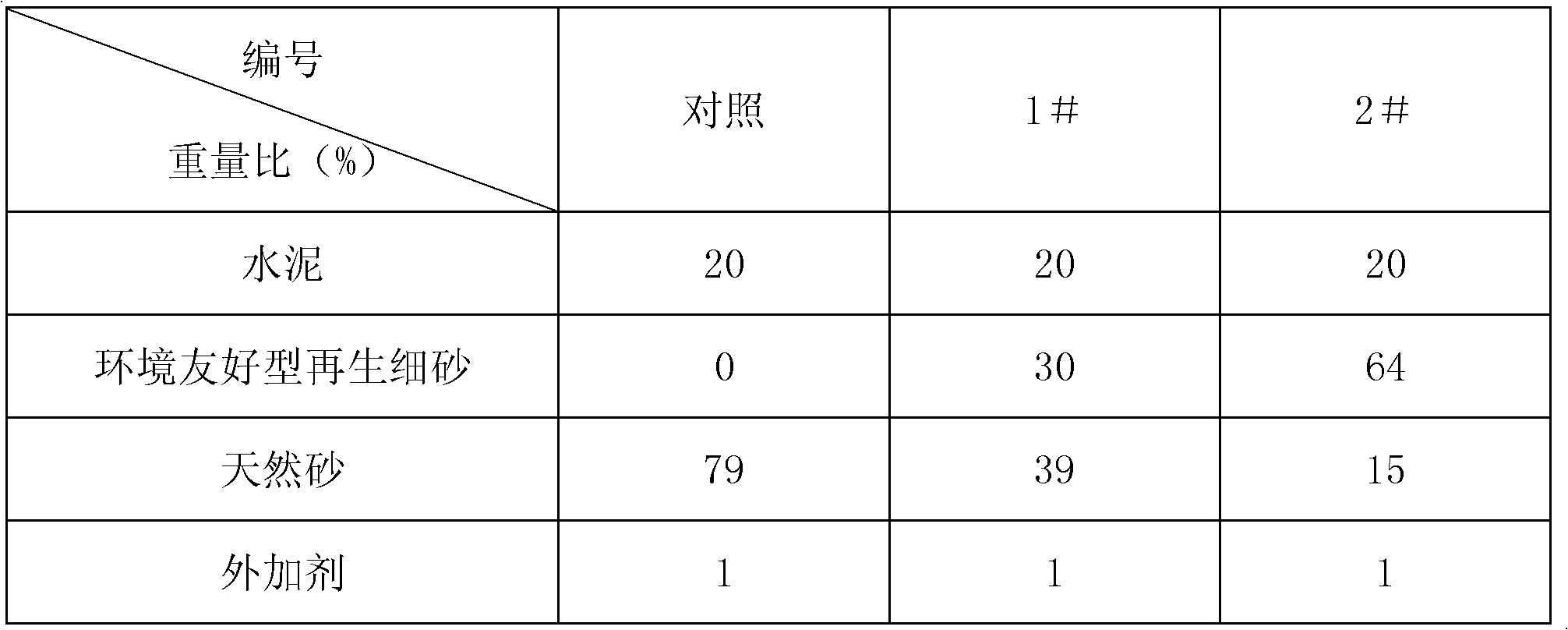

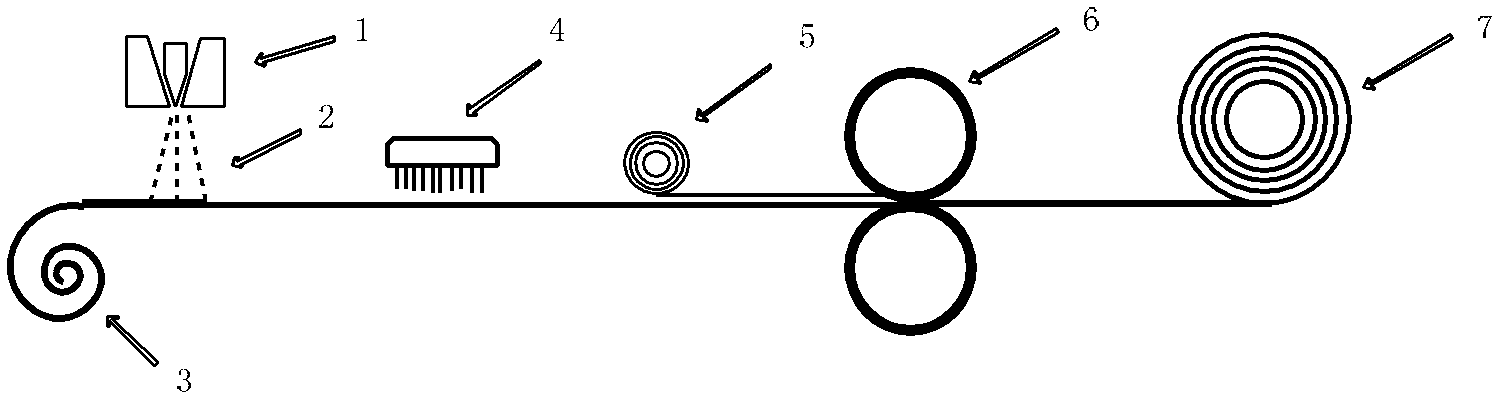

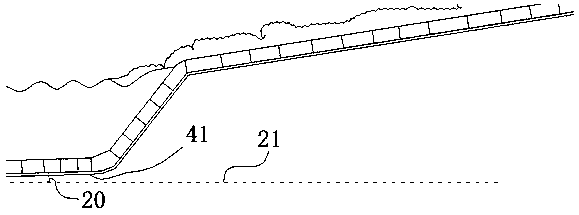

Adjustable soil shovel conveyor

InactiveCN111926870AAddress security threatsAvoid deepMechanical machines/dredgersSoil scienceDrive wheel

The invention discloses an adjustable soil shovel conveyor which structurally includes a machine frame, a push rod arm, a driving wheel, a shovel bucket, and soil loosening mechanisms. The front end of the machine frame is connected with the push rod arm, and the driving wheel is arranged at and is connected with the bottom of the machine frame. The shovel bucket is located at one end of the pushrod arm, and the soil loosening mechanisms are arranged on the two sides of the shovel bucket. The adjustable soil shovel conveyor has the beneficial effects that first, a drill ring in the mechanismis used to be in contact with sandy soil during high-speed rotation and rub against with the sandy soil to destroy the stacking state of the sandy soil so as to enable the sandy soil to turn into a loose state; and second, a squeeze cone is used to break the pressure tension of an air pressure ball to trigger the high-pressure ejection of internal air to disperse the sandy soil covering parts, thesandy soil slide down naturally through the cooperation the air and the parts, the conveyor is prevented from going deep into a sandy soil coverage area, and the risk of being buried is minimized.

Owner:刘培泉

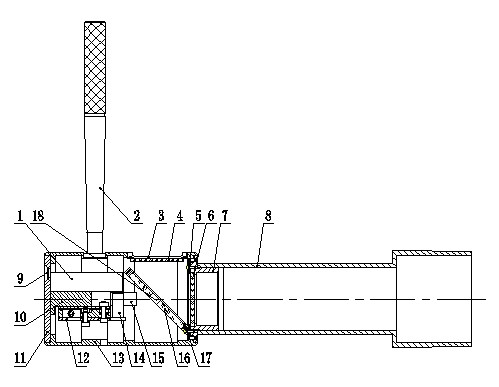

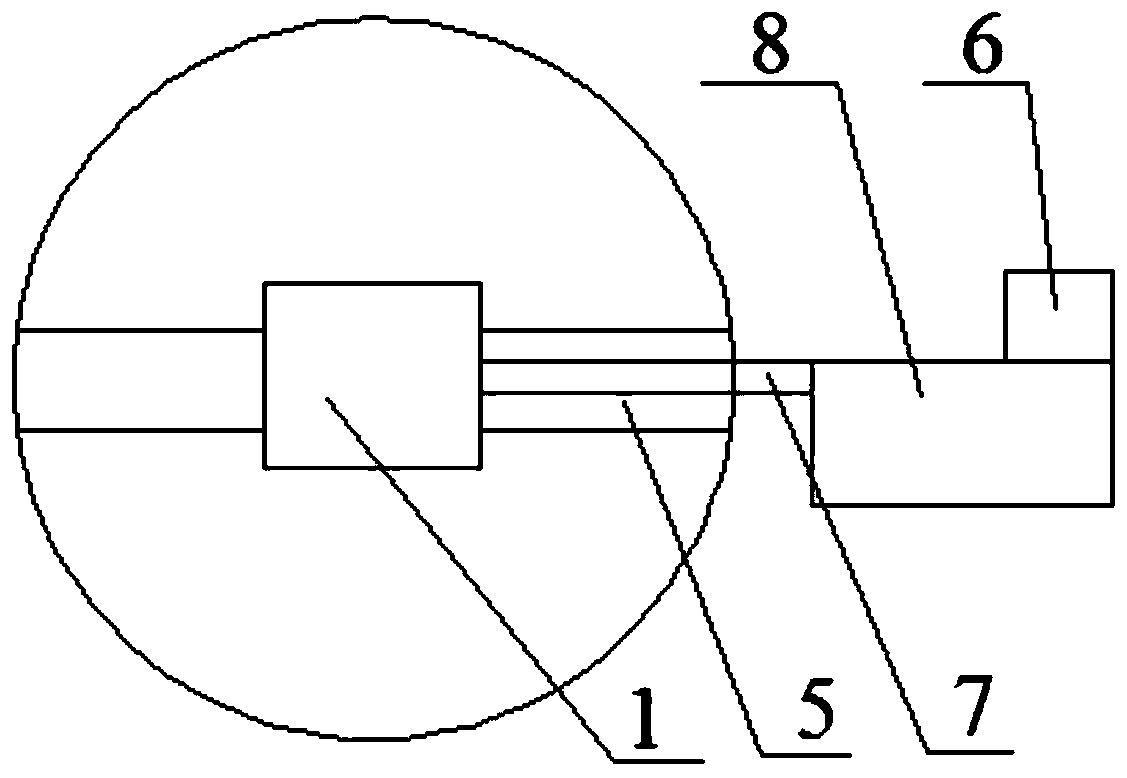

Optical calibrator

The invention discloses an optical calibrator. The technical scheme is that: the optical calibrator comprises a protective cover; the front and rear ends of the protective cover are provided with a front cover and a rear cover; the front cover is a cylinder; the front end of the front cover is provided with a conical surface positioning sleeve; the rear end of the front cover is provided with light-transmitting glass; the protective cover is provided with a view window; the rear end of the front cover is fixedly provided with a reflecting mirror fixing seat; a semi-passing semi-reflecting mirror is embedded into the reflecting mirror fixing seat and corresponds to the view window; an included angle of 45 degrees is formed between the semi-passing semi-reflecting mirror and the conical surface positioning sleeve; a light passing hole is formed in the middle of the semi-passing semi-reflecting mirror; a laser is arranged in the protective cover; and the emergent light of the laser can pass through the light passing hole. The optical calibrator has the advantages of compact and reasonable structure, high positioning accuracy, long service life and novel appearance design.

Owner:山东神戎电子股份有限公司

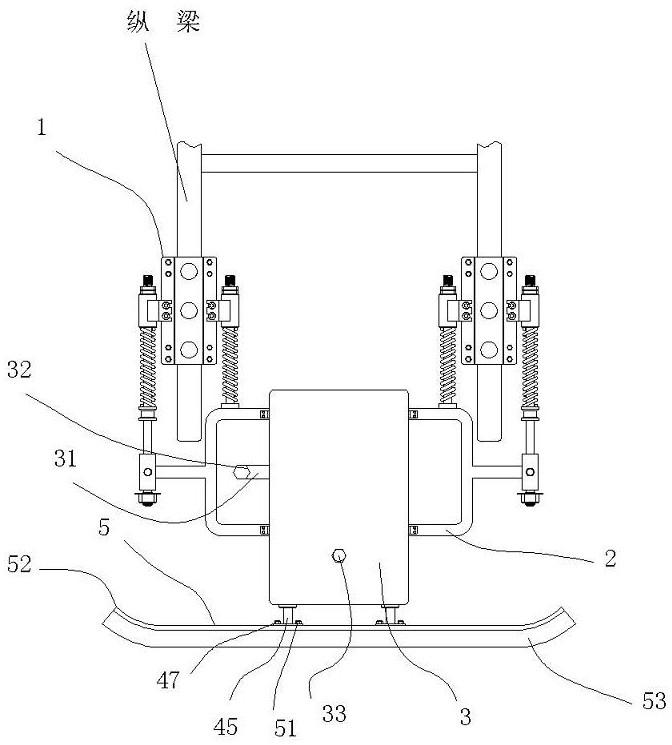

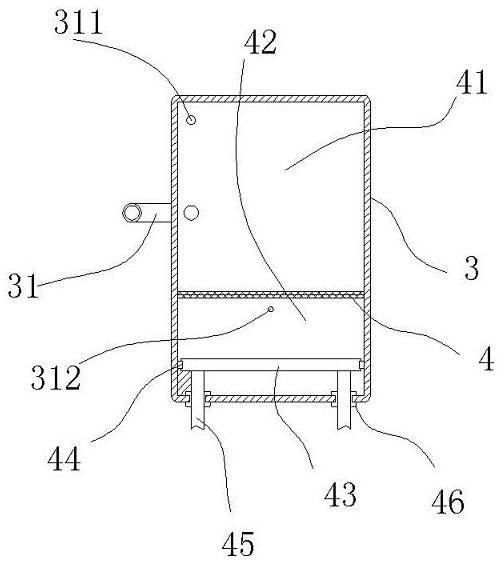

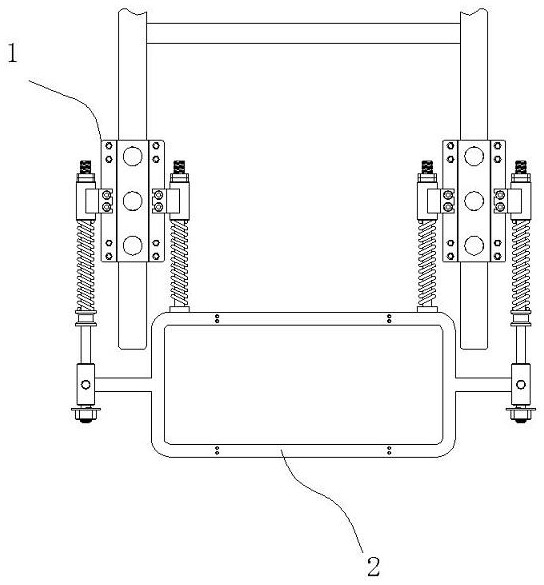

Vehicle bottom hanging type collision protection device

ActiveCN112373426AAvoid breaking the A-pillarAvoid casualtiesVehicular safety arrangmentsSteel platesVehicle frame

The invention discloses a vehicle bottom hanging type collision protection device. The device comprises connecting buffer structures installed on longitudinal beams on the two sides of a vehicle and asquare steel frame installed between the connecting buffer structures on the two sides. Compared with a traditional linear steel frame, the square steel frame can deform to absorb energy, and the energy absorption capacity is higher; the height of the square steel frame is lower than that of the longitudinal beam; by means of the structure, when the square steel frame moves backwards, movement interference between the square steel frame and the total square steel frame is avoided; an energy-absorbing water tank is detachably arranged above the square steel frame, and a partition plate is arranged in the energy-absorbing water tank and is formed by welding double layers of steel plates; higher anti-pressure capability is realized; the device can be installed at the tail of a frame of the trailer, the distance is prolonged, energy is absorbed when the head of the trailer is inserted, and collision damage to the trailer is reduced.

Owner:南京市极可信息科技有限公司

VR-based visual inspection and training system

PendingCN113456012AFading insensitiveReduce complexityCasings/cabinets/drawers detailsEye exercisersInformation processingPhysical medicine and rehabilitation

The invention relates to the technical field of VR visual inspection and training, and discloses a VR-based visual inspection and training system. The system comprises VR equipment and a PC terminal, wherein one side of the VR equipment is fixedly connected with a connecting plate, the top end of the connecting plate is fixedly connected with a spring and a small telescopic rod, the top ends of the spring and the small telescopic rod are provided with a high-strength plastic shell, a wear-resistant coating is arranged on the surface of the high-strength plastic shell, a connecting block is fixedly connected to the bottom end of the high-strength plastic shell, a threaded groove is formed in the connecting block, a connecting rod is arranged in the threaded groove, and a telescopic rod is fixedly connected to the bottom end of the connecting rod. According to the VR-based visual inspection and training system, by arranging a VR device, an optical lens, a PC terminal, a UWB sending module, a UWB receiving module, an information processing module and a VR image presentation module, various brain vision of children can be detected and trained.

Owner:广州亮瞳医疗用品有限公司

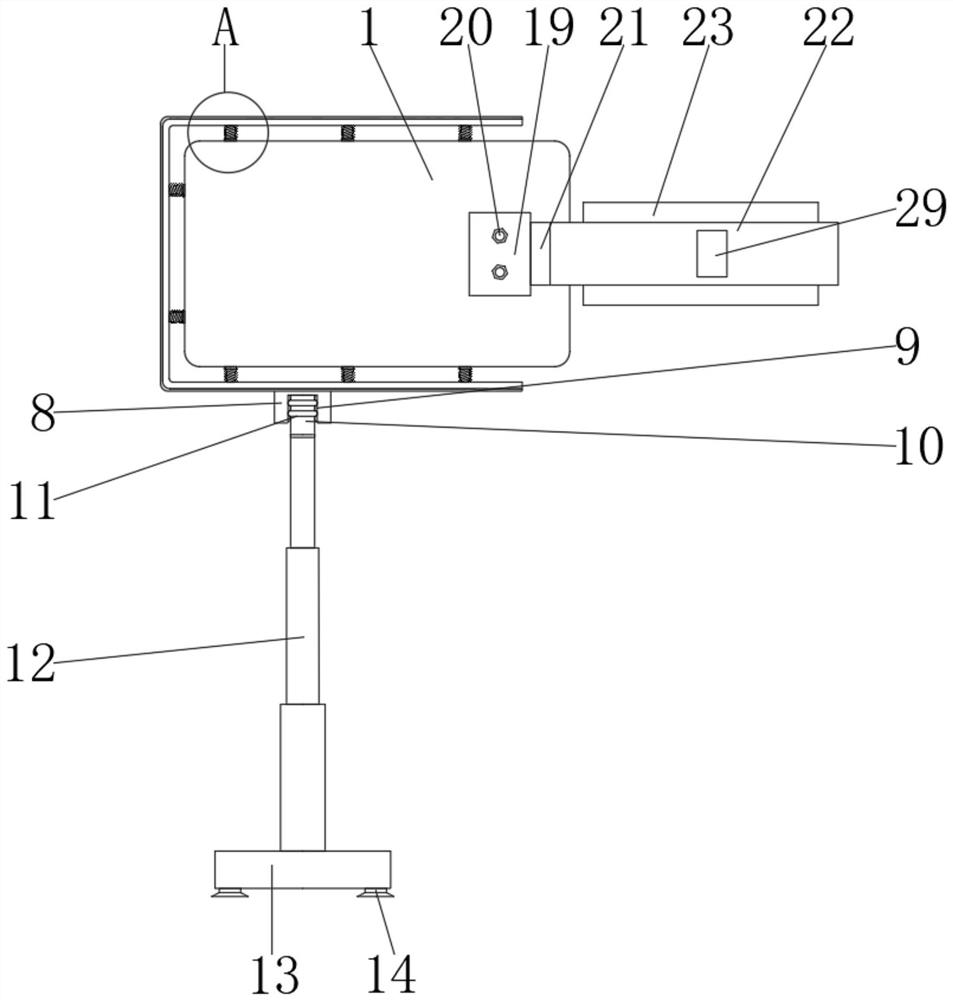

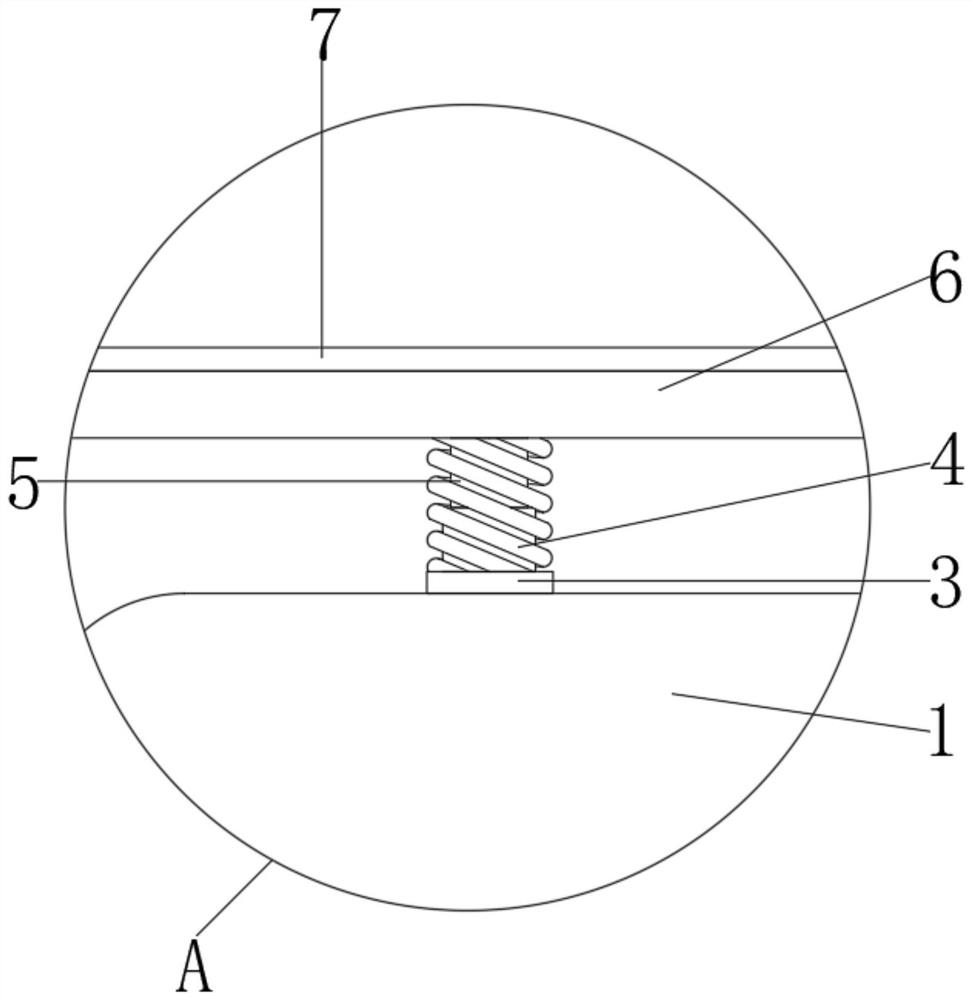

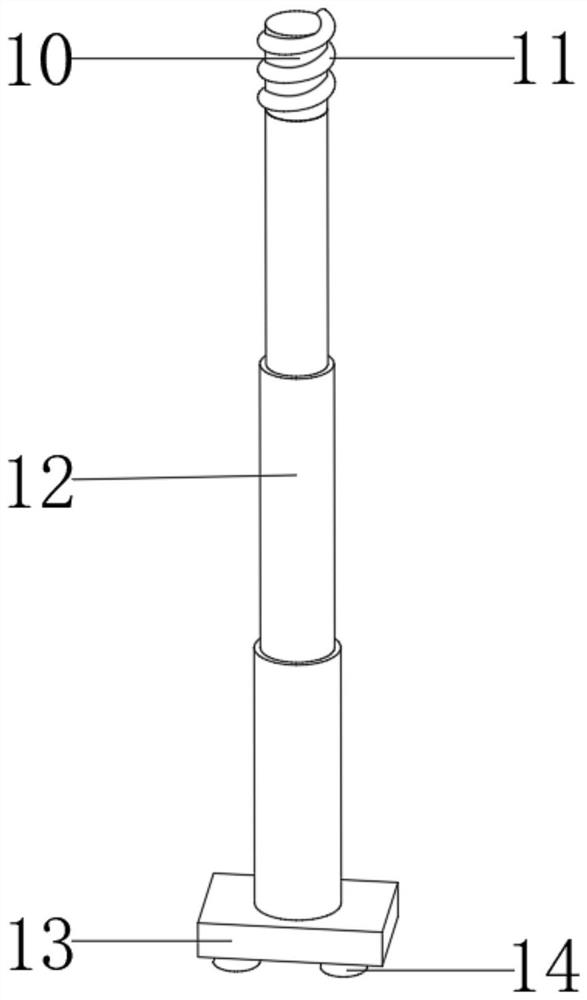

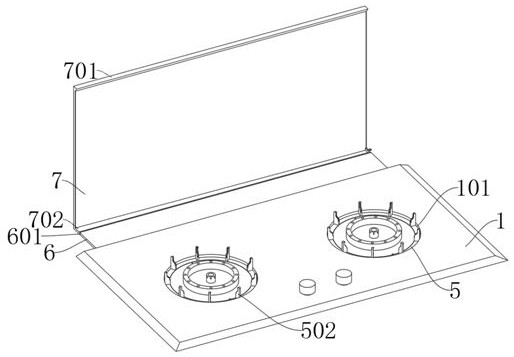

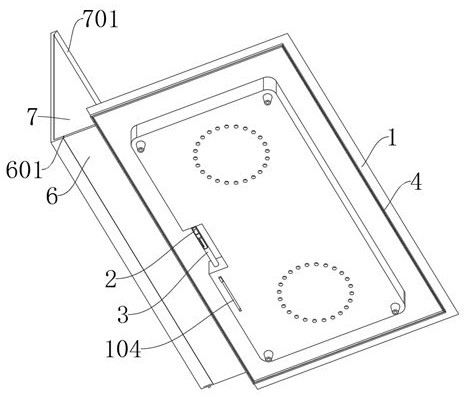

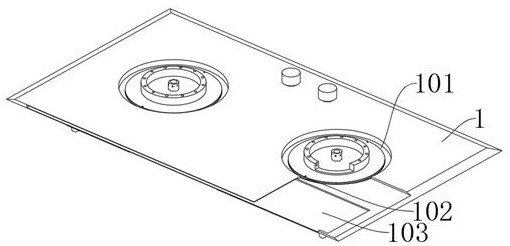

Automatic control type gas energy-saving stove with security functions

InactiveCN112283752AImprove sealingPlay the role of being sizedDomestic stoves or rangesLighting and heating apparatusAutomatic controlProcess engineering

The invention provides an automatic control type gas energy-saving stove with the security function, and relates to the technical field of gas stoves. The automatic control type gas energy-saving stove with the security function aims at solving the problems that when an existing automatic control type gas energy-saving stove is used for a long time, the joint of a gas pipe is prone to aging, the phenomenon of gas leakage easily occurs, and an automatic security reinforcing structure is not arranged. The gas energy-saving stove comprises a main body, a connector, a moving part and a sealing part, wherein the main body is the automatic control type gas energy-saving stove, the outer side of the main body is of an inclined structure, and the moving part and a pull rod are arranged in a bottomgroove through springs. According to the gas energy-saving stove, the connector is used for being arranged at the rear end of the main body, so that when the gas energy-saving stove needs to be used,the connector can be connected to a gas pipe, the gas pipe can sleeve the outer side of the connector and the outer side of an ejector ring, then an ejector pipe is controlled to rotate, so that theejector pipe can push the ejector ring to protrude, and therefore, the ejector ring and the interior of the gas pipe are sealed in a close contact mode, and the sealing effect is better.

Owner:闫志伟

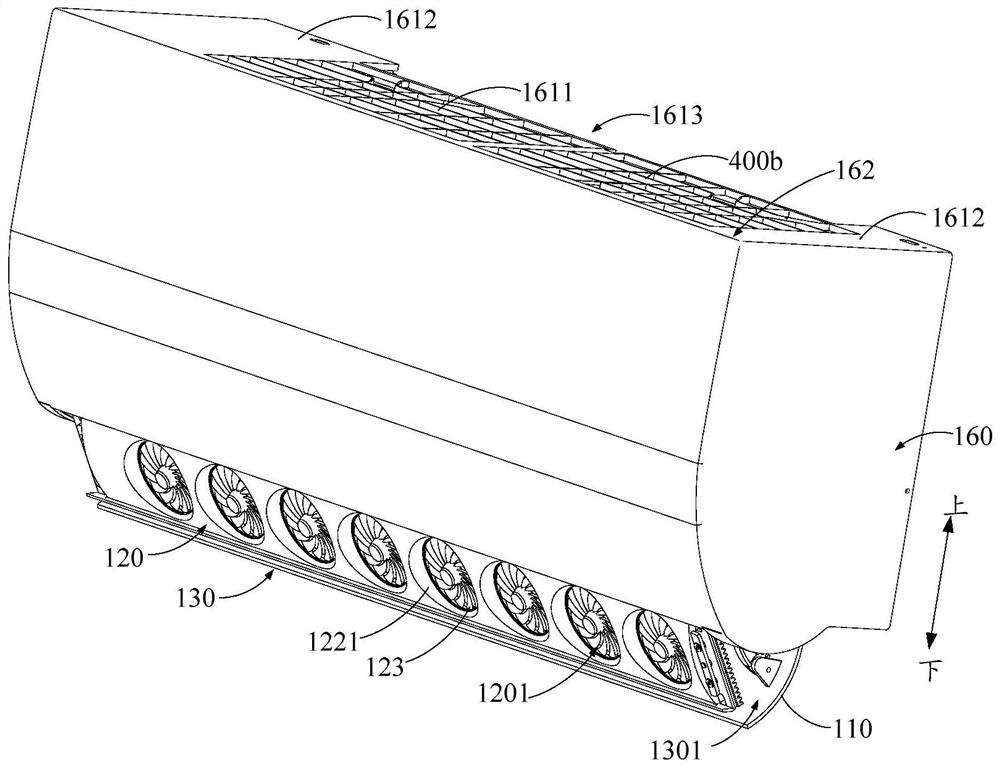

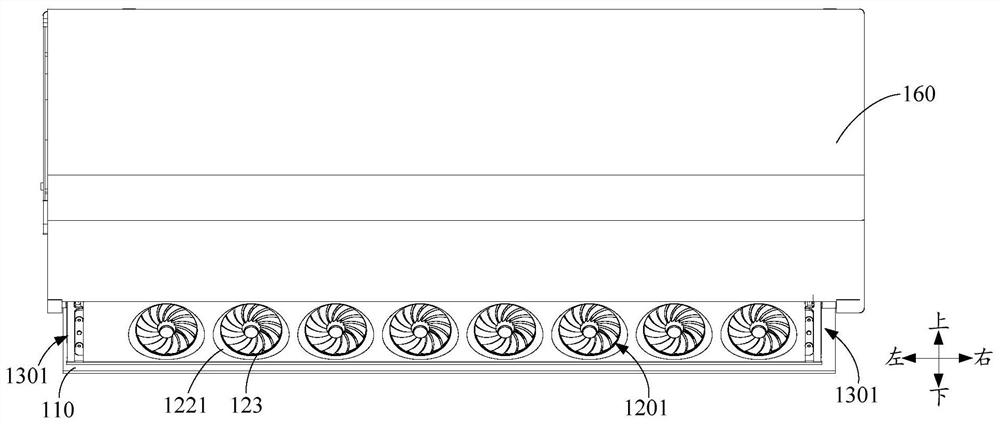

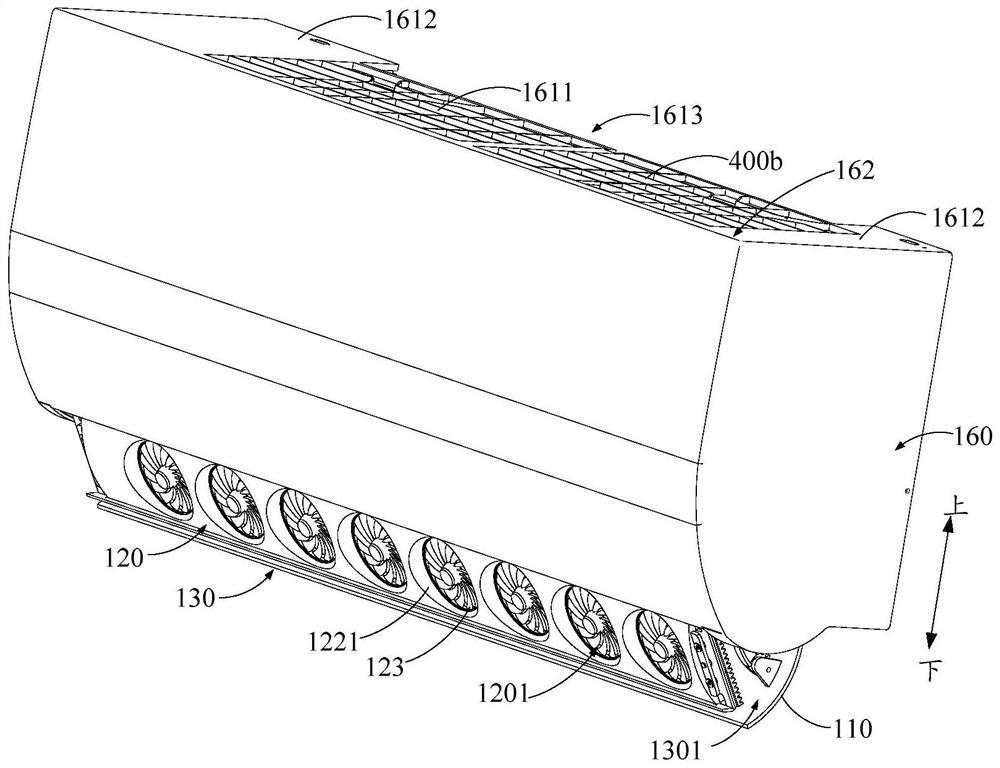

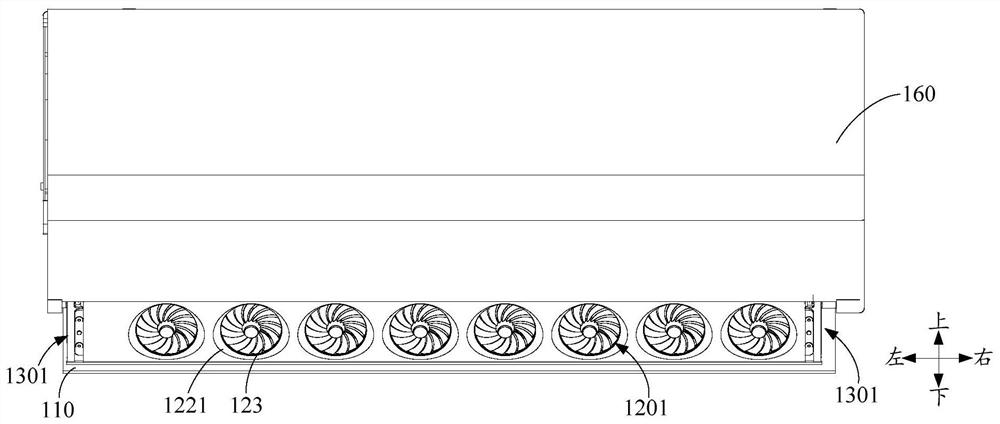

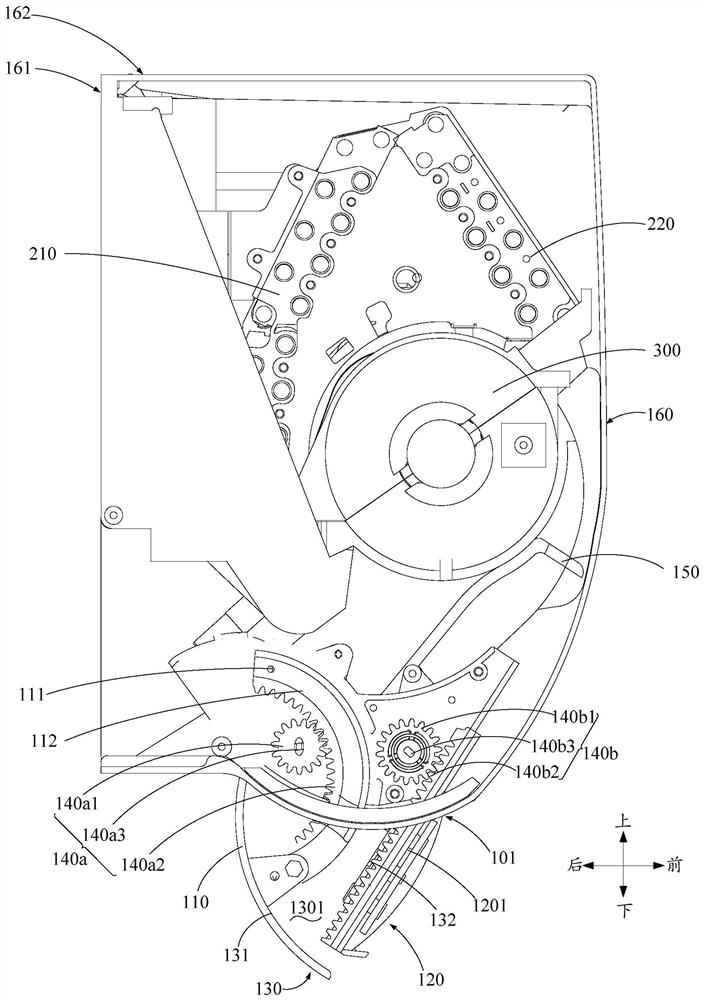

Air conditioner

ActiveCN112413728AAchieve positioningAvoid deepLighting and heating apparatusAir conditioning systemsThermodynamicsEngineering

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

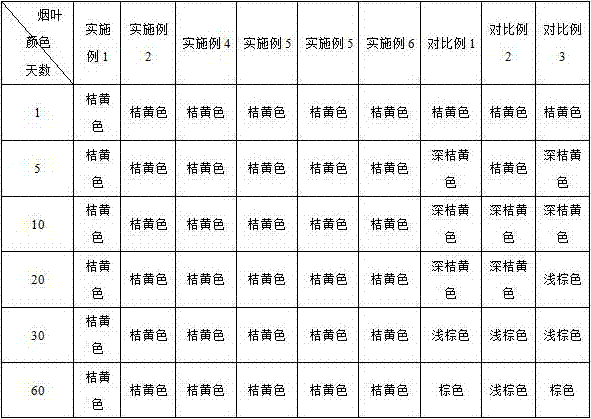

Method of starting to use tobacco leaves stored in hypoxic environment in summer and autumn in Guangdong Province

ActiveCN107495458AControlling the rate of oxidation reactionsQuality assuranceTobacco preparationSufficient timeReaction rate

The invention discloses a method of starting to use tobacco leaves stored in hypoxic environment in summer and autumn in Guangdong Province. The method comprises following steps: S1. unsealing tobacco leaves stored in hypoxic environment in a low-temperature store room / storing the tobacco leaves in the low-temperature store room immediately after unsealing, wherein, the temperature of the low-temperature store room is 0 to 4 DEG C, the oxygen concentration is the normal concentration of the oxygen in the air, and the relative humidity is 55 to 65%; S2. increasing the temperature in the low-temperature store room at a heating rate of 1 to 2 DEG C / 24h and the tobacco leaves can be normally used until the temperature is increased by 20 to 35 DEG C. The method of the invention makes the low oxygen stored tobacco leaves have sufficient time to adapt to the external high oxygen concentration environment after opening by controlling the low temperature and relative humidity; the oxidation reaction rate of polyphenols was controlled effectively, and the rapid and large color change of tobacco leaves after being placed in high oxygen concentration environment was avoided successfully. The quality of tobacco leaves, especially the appearance quality, was effectively guaranteed. And after returning to normal environment, even in a certain period of time storage, color will not change significantly.

Owner:CHINA TOBACCO GUANGDONG IND

Zig air flue K-shaped flow equalizing apparatus with flyash separation

A K-type flow equalizing device with flying ash separated flashback air flue comprises a vertical air flue and a horizontal air flue, the lower end of the vertical air flue is provided with a flue-dust retainer and ash discharge device, the position of the vertical air flue turning to the horizontal air flue is provided with a flue gas turning external coating surface composed of delta wing grilles, the adjacent clearance between two delta wing grilles is communicated with the flue-dust retainer, the entrance of the horizontal air flue is distributed transversely with ascending and descendingsmall air flues, the sum of the entrance cross sections of the ascending and the descending small air flues is equal to section area of the horizontal air flue, the ascending and the descending smallair flues are alternately arranged inside the horizontal air flue and respectively introduces 50 0.000000lue gas to the upper semi-cross section of the horizontal air flue and 50 0.000000lue gas to the lower semi-cross section of the horizontal air flue. The flying ash described by the present invention is separated into the flue-dust retainer by delta wing grilles, which avoids the flue gas master stream from entering the flue-dust retainer and the flying ash from entering the flue gas by secondary entrainment, the ascending and descending small air flue alternate settings is alternately arranged in the horizontal air flue, the present invention realizes to make the severe oblique flow field distribution after acute steering in ultrashort distance evenly distribute in the whole air flue cross section rapidly.

Owner:XIAN THERMAL POWER RES INST CO LTD

Rolling device for candies

The invention discloses a rolling device for candies. The rolling device comprises a pedestal, an internal box, an external box and a rolling mechanism. The external box is fixed on the periphery of the pedestal. The lower end of the internal box is provided with a cutter with its cutting point facing the pedestal. The outer wall of the internal box and the inner wall of the external box are detachably and elastically connected. The rolling mechanism comprises a press roll, two ends of which are provided with elastic parts. The elastic parts pass through the internal box and are connected to the wall of the external box. In addition, two ends of the press roll are both connected to walls of the internal and external boxes in a horizontal sliding manner. The technical problem to be solved in the invention is to provide a rolling device which has high safety factor and is used for candies.

Owner:CHONGQING YU NIU FOOD CO LTD

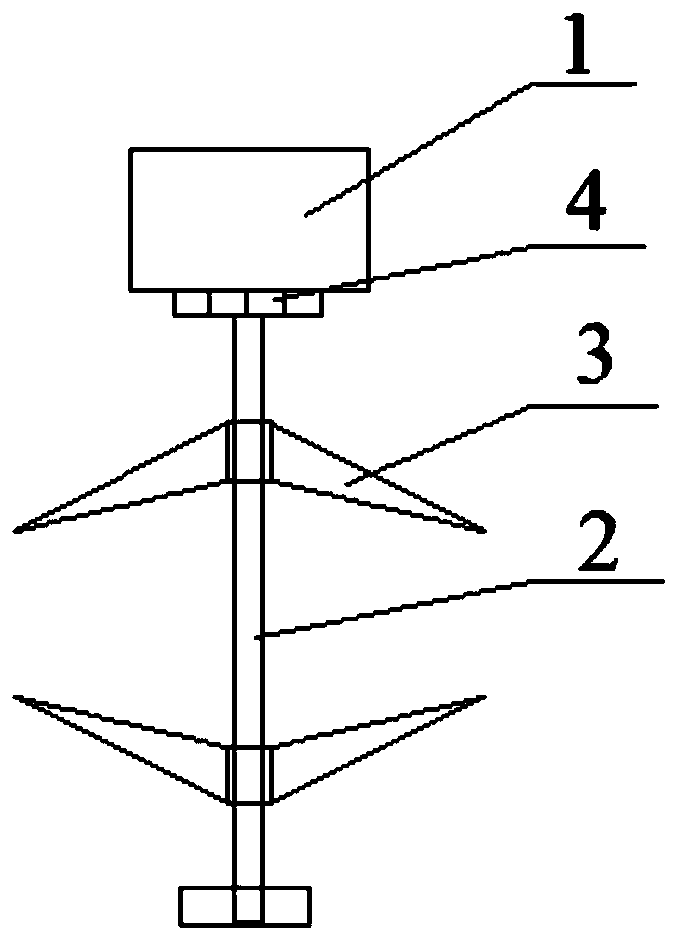

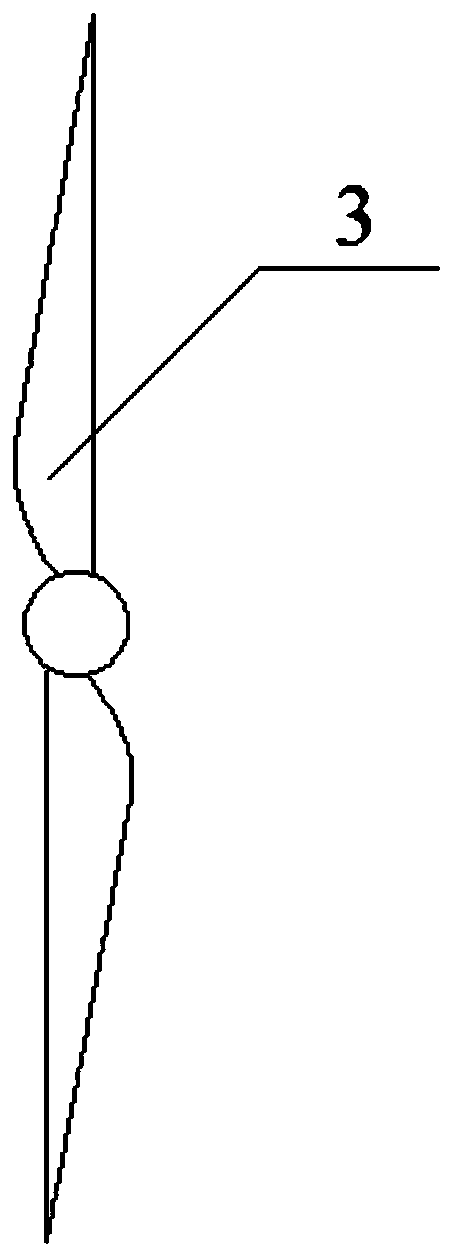

Hydraulic stirring device

PendingCN110773021ALow powerReduce energy consumptionTransportation and packagingRotary stirring mixersBiogasProcess engineering

The invention provides a hydraulic stirring device. The device comprises a hydraulic motor, a driving unit for driving the hydraulic motor, and a rotating shaft with one end arranged at the bottom ofa pretreatment tank. The output end of the hydraulic motor is connected to the other end of the rotating shaft, a stirring assembly is arranged on the rotating shaft, and one end of the rotating shaftis arranged at the bottom of the pretreatment tank, thus preventing the rotating shaft equipped with the stirring assembly from going deep into the pretreatment tank, and during installation, the hydraulic motor is connected to the other end of the rotating shaft. The hydraulic motor converts liquid pressure energy provided by the driving unit into mechanical energy with high torque and low rotating speed, namely torque and rotating speed, and then drives the rotating shaft connected to the output end of the hydraulic motor to move, so that the stirring assembly on the rotating shaft can rotate, rotation of the stirring assembly drives the mixing rotation in a biogas slurry tank, and the mixture can be fully mixed. According to the arrangement, the hydraulic motor and the driving unit ofthe hydraulic motor are adopted for cooperation, the consumed power is reduced, the energy consumption is lowered, and the energy is saved.

Owner:徐州市环能生态技术有限公司 +1

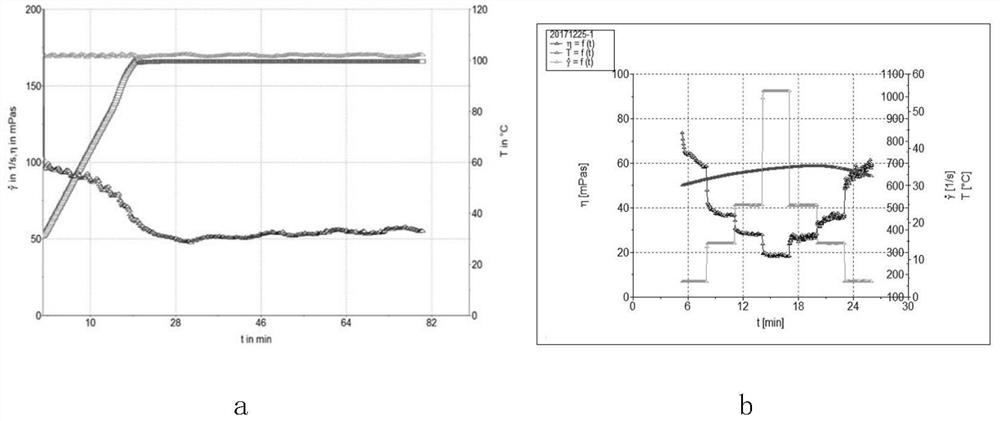

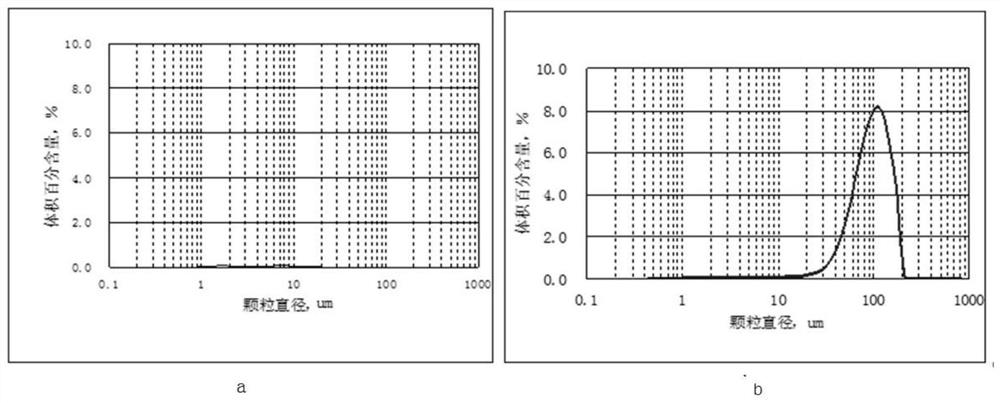

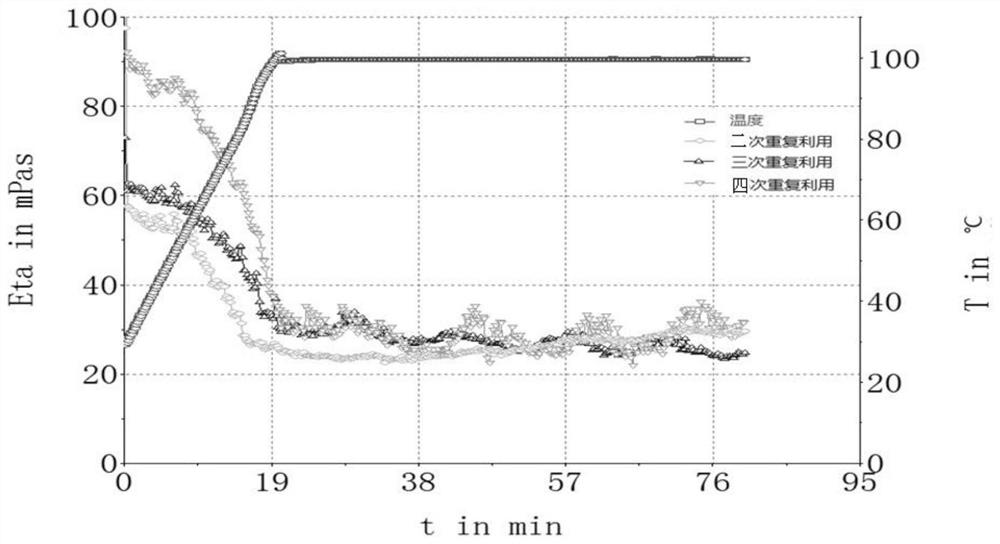

Low-filtration-loss long-seam forming clean fracturing process

The invention relates to the technical field of oil and gas field production and development, in particular to a low-filtration-loss long-seam forming clean fracturing process. According to the process, a weakly acidic clean fracturing fluid which is low in residue, low in damage, good in temperature resistance, shearing resistance and sand carrying performance and capable of being used immediately after being prepared on site and being continuously mixed is matched with a novel efficient filtrate loss reducer, the filtrate loss property of the clean fracturing fluid is greatly reduced throughthe novel efficient filtrate loss reducer, the fracture forming performance of the clean fracturing fluid is improved, the damage to a reservoir can be effectively reduced, the filtration loss of theclean fracturing fluid in the reservoir during fracturing can be reduced, fluid consumption of the fracturing fluid is effectively reduced under the same fracturing scale, and low-filtration-loss clean fracturing long-seam forming is realized. According to the process, respective defects of the clean fracturing fluid and a guanidine gum fracturing fluid are overcome, the filtration loss of the clean fracturing fluid in the reservoir during fracturing construction is reduced, the fluid fracture forming efficiency and the construction efficiency are improved, the fracturing fluid consumption and the damage to the reservoir are reduced, a stratum is effectively protected, and the water saving and reduction of a fracturing comprehensive cost are facilitated.

Owner:杨凌单色生物科技有限公司

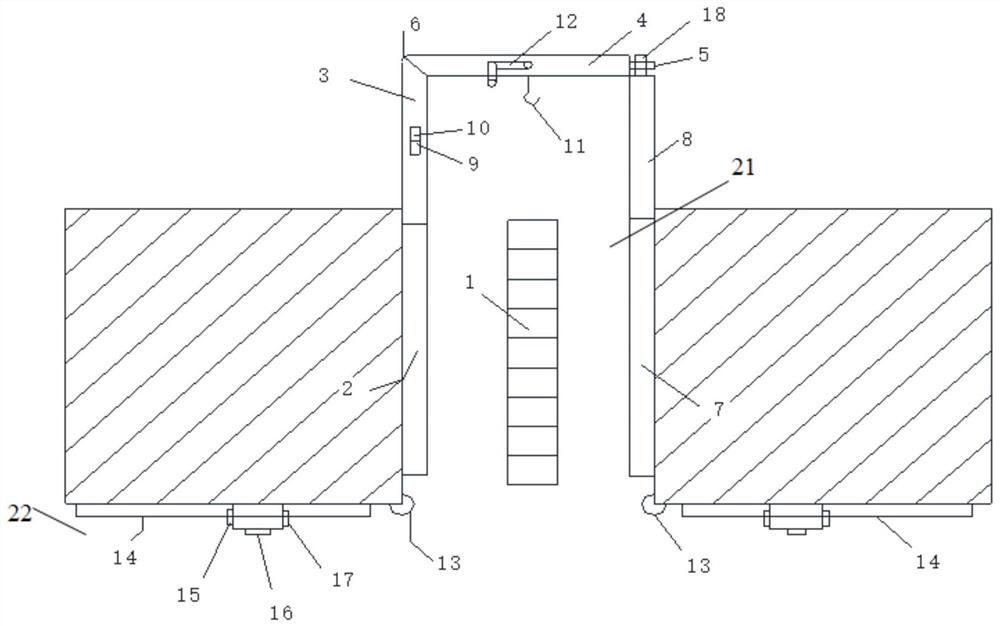

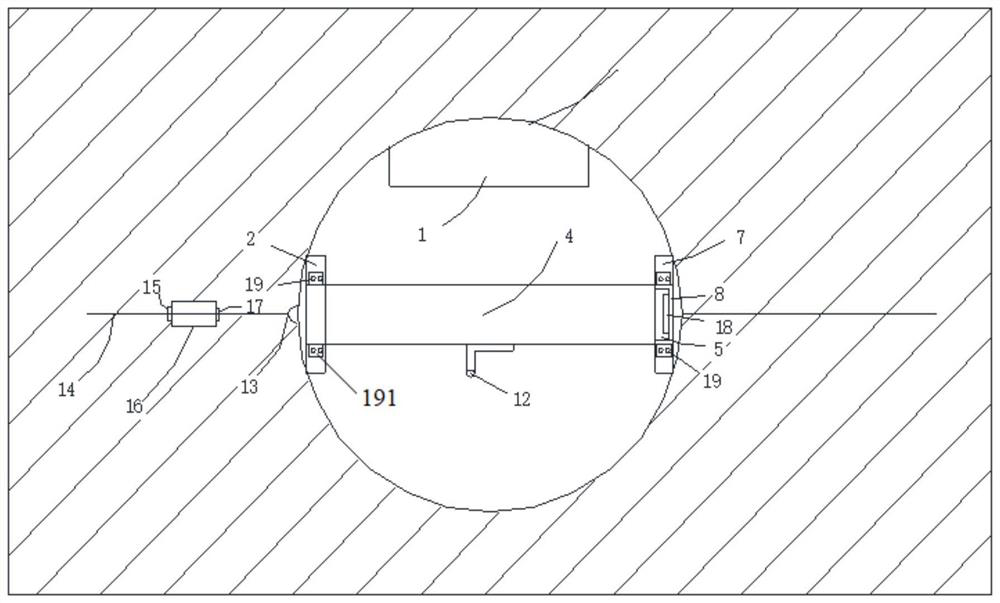

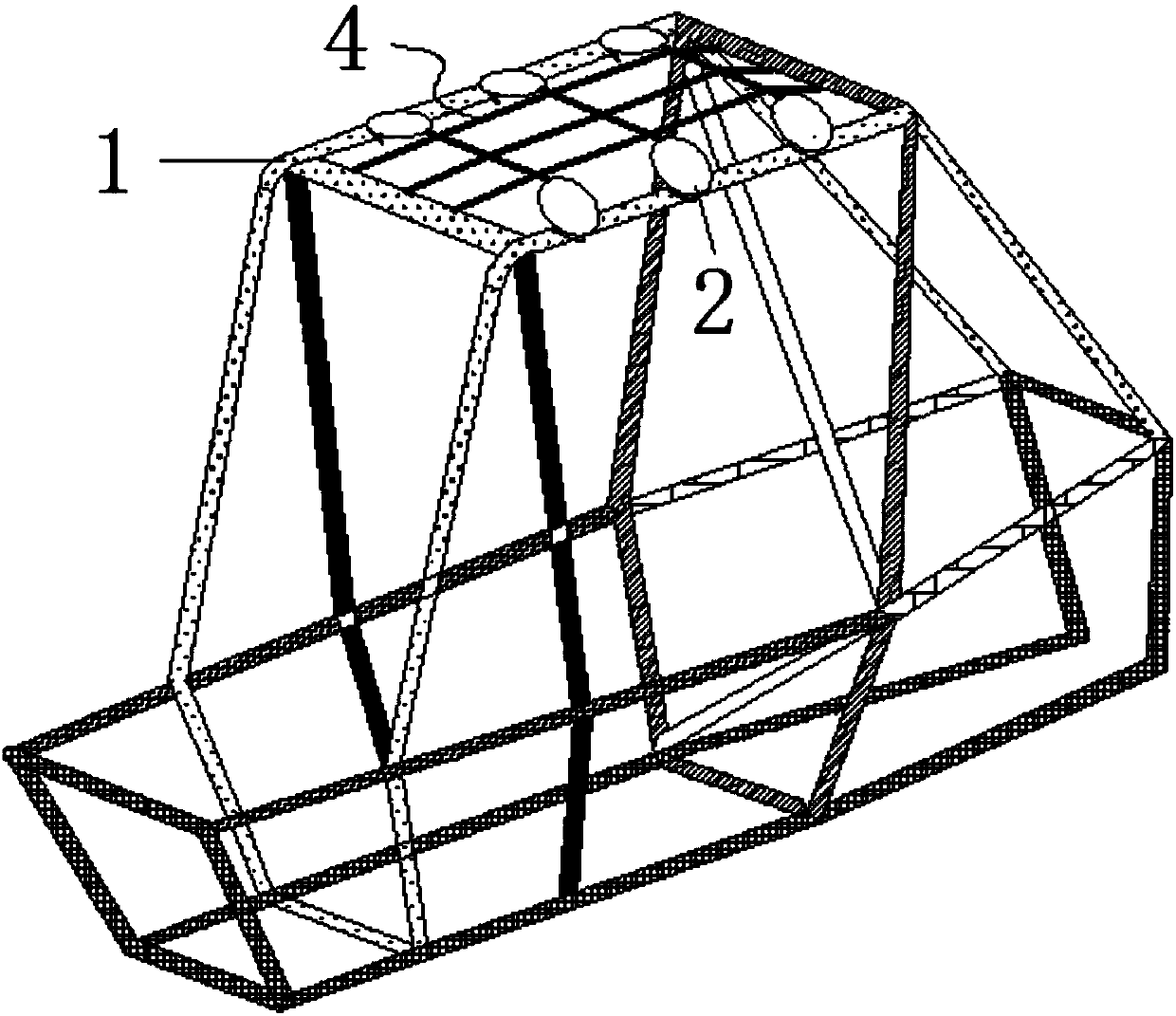

Safety protection rescue device for limited space operation and using method of safety protection rescue device

The invention discloses a safety protection rescue device for limited space operation. The safety protection rescue device is characterized by comprising a rescue bracket box I, a rescue bracket box II, a rescue bracket, a safety integration mechanism and a rescue mechanism, wherein the rescue bracket box I and the rescue bracket box II are fixedly connected to a well wall, the rescue bracket is connected to the rescue bracket box I and the rescue bracket box II, the safety integration mechanism is connected to a underground passage and the rescue bracket, the rescue mechanism is connected to the rescue bracket, an upper and lower channel crawling ladder is arranged on the well wall, and the rescue bracket box I and a rescue bracket box II are arranged on the two sides, forming an angle of 90 degrees with the crawling ladder, of the well wall correspondingly, the rescue bracket comprises a left vertical rod, a transverse rod and a right vertical rod, the left vertical rod is connected to the rescue bracket box I, the right vertical rod is connected to the rescue bracket box II, and the two ends of the transverse rod are connected to the top of the left vertical rod and the top of the right vertical rod correspondingly to form a door-frame-shaped structure. The invention further discloses a using method of the safety protection rescue device for the limited space operation.

Owner:WUHU WANJIANG INTPROP OPERATION CENT CO LTD

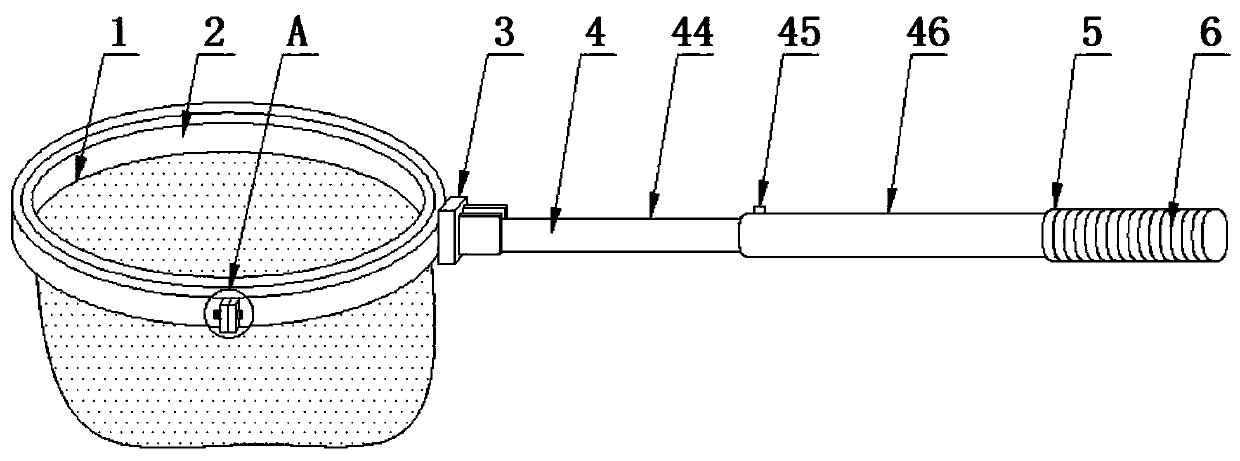

Collecting device for tiny insects in water body

InactiveCN110367222AAvoid deepEnsure the safety of life and propertyInsect catchers and killersEngineeringInsect

The invention relates to the technical field of insect collecting equipment, and discloses a collecting device for tiny insects in a water body. The device is characterized in that a filter screen replacing component is arranged on the left side of a transition block; a fine-hole filter screen is arranged below the filter screen replacing component; a movable telescopic device is arranged on the right side of the transition block; anti-skid lines are sleeved outside the handle; and the telescopic support rod, the telescopic fixing rod and the fixing clamping pin in the movable telescopic device can adjust the adaptive length, aiming at the fact that it is particularly convenient to collect tiny insect samples in field river water to avoid collectors from going deep into water or river grass, on the basis of convenience, the life and property safety of the collectors during the collection of tiny insect samples is ensured, the filter screen replacement component can replace or clean andmaintain the fine-hole filter screen, so that the loss of the fine-hole filter screen during the collection of tiny insect samples is reduced; and reuse of the fine-hole filter screen can reduce thecost, and conform to the theme of today's green recyclable era.

Owner:GUIZHOU UNIV

Composite type fiber filtering material and preparation method thereof as well as filtering bag

ActiveCN102512881BSmall apertureDurableDispersed particle filtrationSynthetic resin layered productsFilter materialAramid

The invention provides a composite type fiber filtering material and a preparation method thereof as well as a filtering bag made by the same. The composite type fiber filtering material comprises a supporting layer, a fiber web layer and a PTFE (Polytetrafluoroethylene) covering film, wherein the supporting layer is made of polyphenylene sulfide fiber, polytetrafluoroethylene fiber, meta-aramid fiber or polyimide fiber; the fiber web layer is made of polyphenylene sulfide fiber and arranged on the supporting layer; and the PTFE covering film is arranged on the fiber web layer; and the fiber web layer is formed by polyphenylene sulfide fiber webs with an average diameter of 2-10 microns. According to the composite type fiber filtering material disclosed by the invention, the fiber web layer, which is formed by ultra-thin fiber webs on the traditional acupuncture filtering felt through a melt spinning process, is added. The fiber web layer is in a more abundant microcellular structure with a smaller aperture, so that smoke and tiny dust are effectively separated outside an ash collecting layer, the tiny dust is prevented from entering into the filtering material, and the filtering efficiency is improved.

Owner:CHINESE TEXTILE ACAD +2

Racing-car anti-rolling annular overhead component

The invention discloses a racing-car anti-rolling annular overhead component. The racing-car anti-rolling annular overhead component comprises a racing-car top component, toroidal iron discs, hollow cylindrical fixing blocks and reinforcement bars, the racing-car top component is formed by welding four steel pipes, the three hollow cylindrical fixing blocks symmetrically sleeve the outer ends of the steel pipes on the two sides correspondingly, the toroidal iron discs are welded to the hollow cylindrical fixing blocks, the positions, between the symmetrical toroidal iron discs, on the steel pipes on the two sides are connected in a welded mode through the reinforcement bars, the three reinforcement bars perpendicular to the tops of the reinforcement bars are welded to the tops of the reinforcement bars, and the two ends of the three reinforcement bars are welded to the other two steel pipes of the racing-car top component correspondingly. According to the racing-car anti-rolling annular overhead component, the multiple toroidal iron discs are fixed to the steel pipes of the top of a car, then connected and fixed through reinforcements, thus an upward protruding steel welding groupis additionally arranged at the top of the car, buffer can be effectively achieved during overturning of the racing-car, the multiple reinforcements can prevent a shell at the top of the car from extending to the interior, a driver can be effectively protected, and the degree of damage of the car is decreased.

Owner:刘丽婷

Method for treating low-tin materials through reverse expanding rotary kiln

PendingCN109825715ALow priceLess investmentRotary drum furnacesProcess efficiency improvementCombustionDevice failure

The invention discloses a method for treating low-tin materials through a reverse expanding rotary kiln. After the low-tin materials containing 2% to 12% of Sn are mixed with raw coal, the mixture isconveyed into the reverse expanding rotary kiln; under the action of high-temperature smoke generated by combustion in a barrel, material drying, material melting and tin reduction volatilization arecompeted in sequence, and thin sulfiding volatilization is completed under the combined action of pyrite powder; stannic oxide powder is generated in the smoke, and finally the stannic oxide powder inthe smoke is recycled outside the barrel of the rotary kiln; and meanwhile smelted common solid waste residues are generated. The rotary kiln comprises the obliquely arranged barrel. The barrel is sequentially provided with a reaction pond section, a smelting section and a drying section from front to back. A melting reaction pond is formed in the lower portion of a cavity of the reaction pond section. The bottom face section of the reaction pond section is reversely expanded from front to back. When the reverse reducing reaction pond is utilized for treating the low-tin materials, the investment is low, the structure is simple and reasonable, operation is easy, and the number of equipment failures is small.

Owner:株洲湘三特环保有限公司

Air conditioner

ActiveCN112413727AAchieve positioningAvoid deepLighting and heating apparatusAir conditioning systemsEngineeringPhysics

The invention provides an air conditioner. The air conditioner comprises an air conditioner air outlet, an air guide plate and an air diffusion assembly. The air diffusion assembly and the air guide plate are spliced to define a cavity, part or all of the cavity is located on the outer side of the air conditioner air outlet, the cavity communicates with the air conditioner air outlet, an air diffusion structure is formed on the air diffusion assembly, and the air diffusion structure is suitable for exhausting air and enabling blown-out air to be diffused and flow. According to the air conditioner provided by the scheme, the air diffusion structure is utilized, air blown out of the air diffusion structure can flow in a diffused manner, and wind-feeling-free air outputting is achieved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

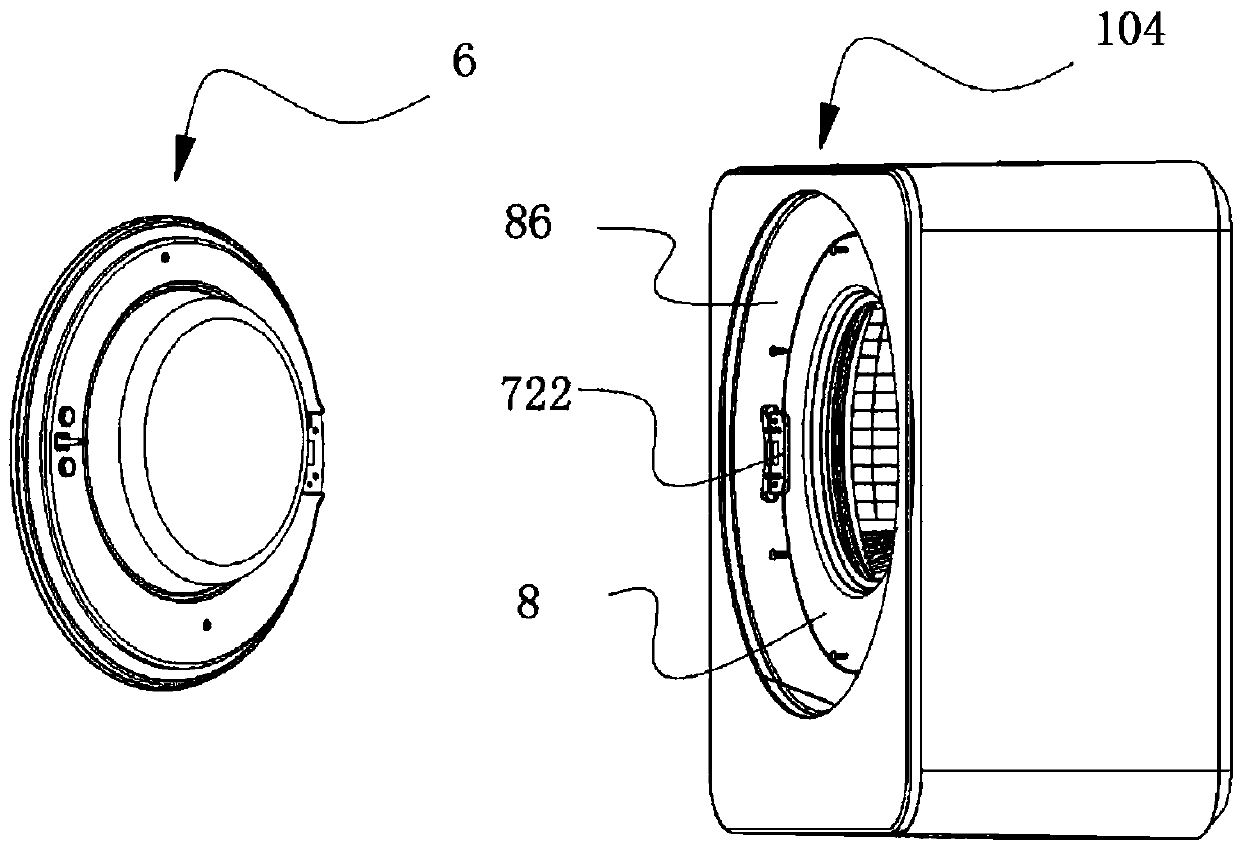

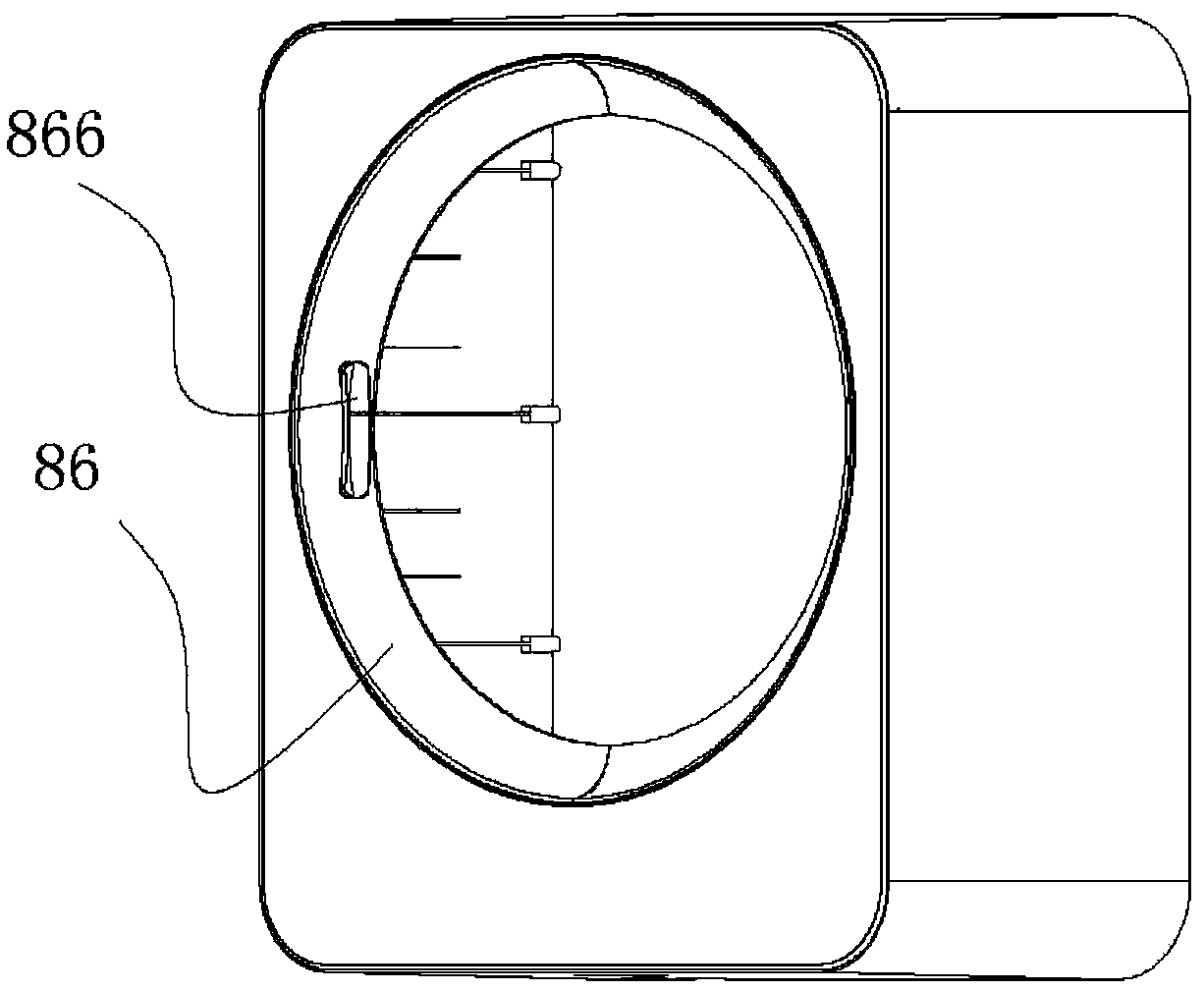

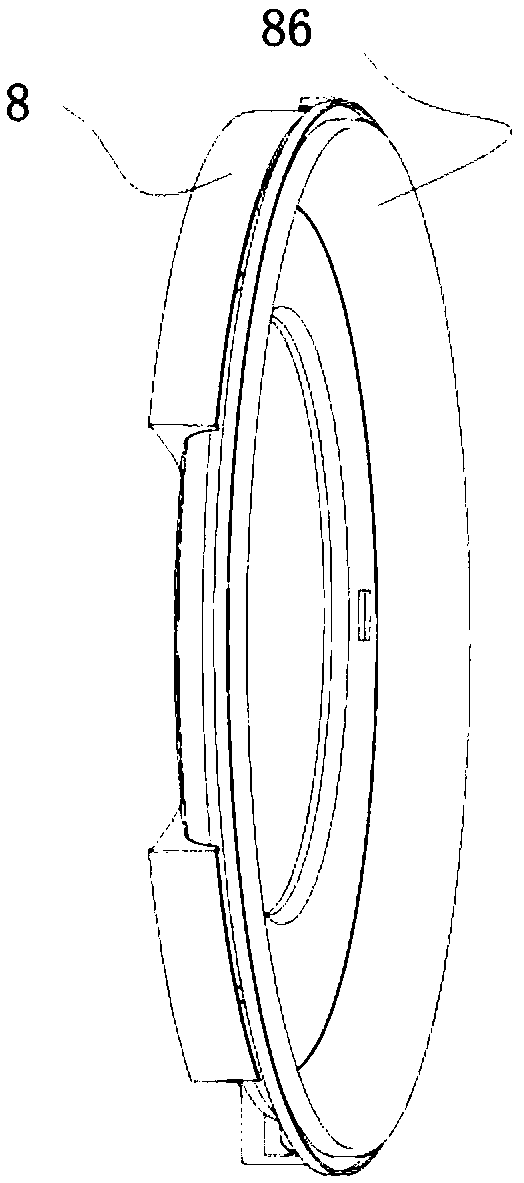

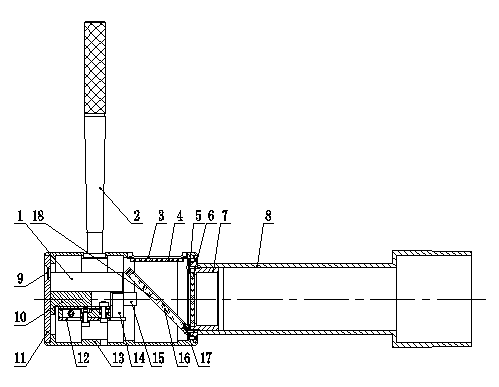

Wall-mounted clothes treatment device

PendingCN110952288AImprove aestheticsImprove the safety of useOther washing machinesTextiles and paperStructural engineeringMechanical engineering

The invention discloses a wall-mounted clothes treatment device. The wall-mounted clothes treatment device comprises a body and a door body which are matched, and further comprises a front part assembling component and a hinge, wherein the front part assembling component is arranged on the side, facing the door body, of the body and forms at least partial contour of a clothes putting opening, andthe middle of the front part assembling component is provided with a vacancy structure allowing clothes to be put; and the hinge is used for hinging the door body and the body, the hinge is arranged between the front part assembling component and the body, and the front part assembling component at least covers at least part of the side, facing the door body, of the hinge. The wall-mounted clothestreatment device provided by the invention improves the stability of hinge installation and ensures uniform stress distribution at the connection position.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Optical calibrator

The invention discloses an optical calibrator. The technical scheme is that: the optical calibrator comprises a protective cover; the front and rear ends of the protective cover are provided with a front cover and a rear cover; the front cover is a cylinder; the front end of the front cover is provided with a conical surface positioning sleeve; the rear end of the front cover is provided with light-transmitting glass; the protective cover is provided with a view window; the rear end of the front cover is fixedly provided with a reflecting mirror fixing seat; a semi-passing semi-reflecting mirror is embedded into the reflecting mirror fixing seat and corresponds to the view window; an included angle of 45 degrees is formed between the semi-passing semi-reflecting mirror and the conical surface positioning sleeve; a light passing hole is formed in the middle of the semi-passing semi-reflecting mirror; a laser is arranged in the protective cover; and the emergent light of the laser can pass through the light passing hole. The optical calibrator has the advantages of compact and reasonable structure, high positioning accuracy, long service life and novel appearance design.

Owner:山东神戎电子股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com