Zig air flue K-shaped flow equalizing apparatus with flyash separation

A fly ash separation and flue technology, which is applied in lighting and heating equipment, etc., can solve the problems of catalyst wear, uniformity of the velocity distribution of difficult flue gas, and active passivation, and achieve the effect of uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

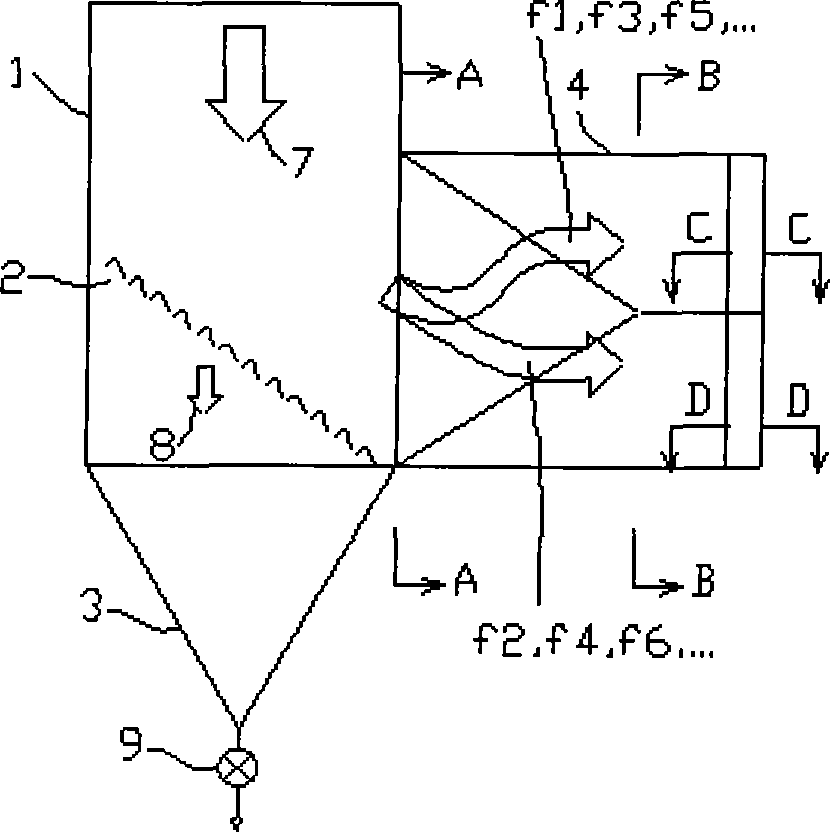

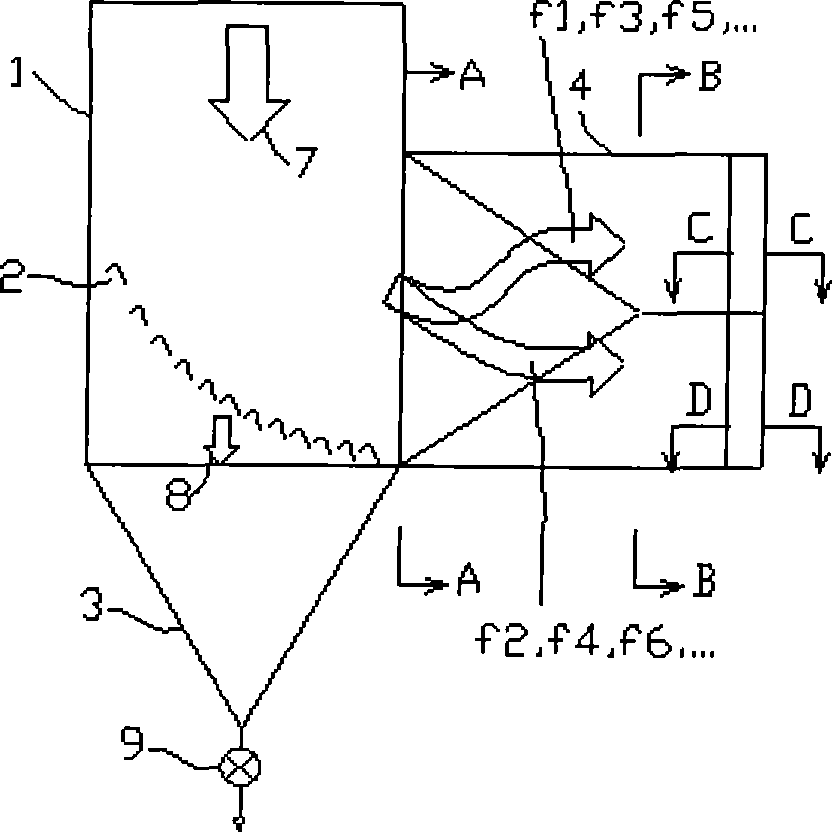

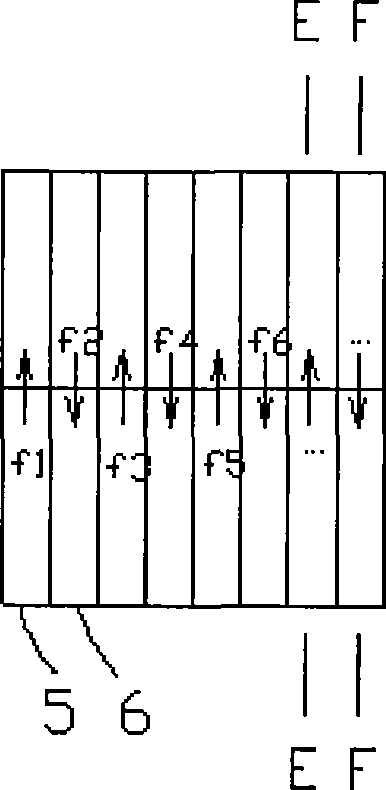

[0015] see Figure 1a , Figure 1b , 1 is the vertical flue, 2 is the delta-wing grille, 3 is the ash collecting hopper, 4 is the horizontal flue, 7 is the flue gas flowing vertically downward, 8 is the flue gas that enters the collector through the delta-wing grille 2 under the action of inertia The fly ash in the ash hopper 3, 9 is the ash discharge device, f1, f3, f5, ... are respectively the flake flue gas flow led to the upper half section of the horizontal flue through the upward small flue, f2, f4, f6, ... .Respectively, the sheet flue gas flow led to the lower half section of the horizontal flue through the small downward flue. The flue gas from the economizer is connected with the vertical flue 1 and the horizontal flue 4, and the lower end of the vertical flue 1 is provided with an ash collecting hopper 3 and an ash discharge device 9, and the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com