Wall-mounted clothes treatment device

A clothing processing equipment and wall-mounted technology, which is applied to other washing machines, textiles and papermaking, household appliances, etc., can solve problems such as affecting the structural integrity around the injection port, increasing the size of the connection position, affecting the appearance of the equipment, etc., to increase the aesthetics. , the effect of reducing the volume and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

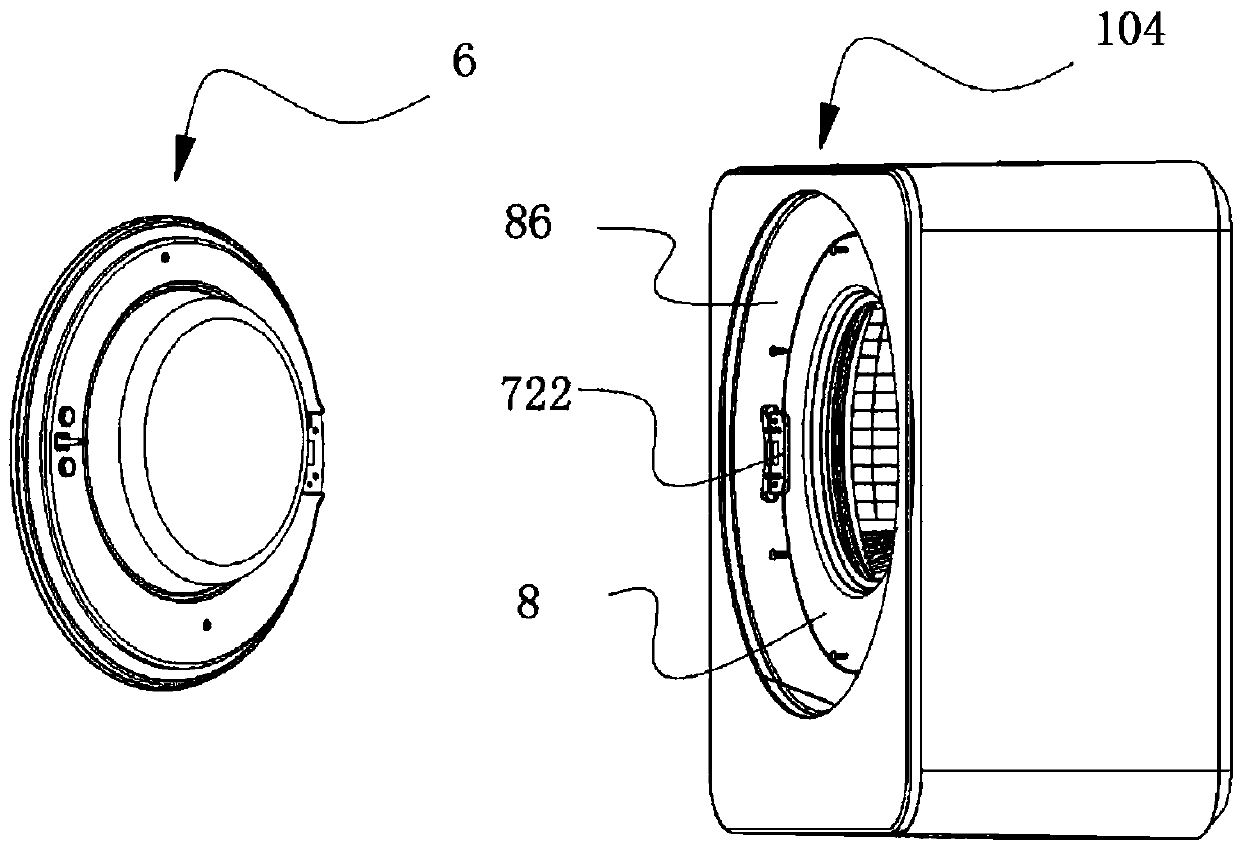

[0050] Such as Figure 1 to Figure 9 As shown, the hinge 72 of the wall-mounted laundry processing device in this embodiment includes a hinge base 721 connected to the body 104 and a movable end 722 pivotably connected to the hinge base 721, and the movable end 722 is connected to the hinge base 721. The door body 6 is connected, and the front assembly component 860 completely covers the hinge seat 721 on the side facing the door body 6 . In this embodiment, through the hidden design of the hinge, the range of action of the hinge and the part of the range of motion exposed to the outside of the body are also greatly reduced, preventing small objects from penetrating into the movable part of the hinge, and also avoiding when the user operates Mistake your fingers deep into the gap between the hinge and the door body to improve the safety of the device. In order to ensure the hinge performance and connection performance of the hinge, the size of the hinge seat is often larger t...

Embodiment 2

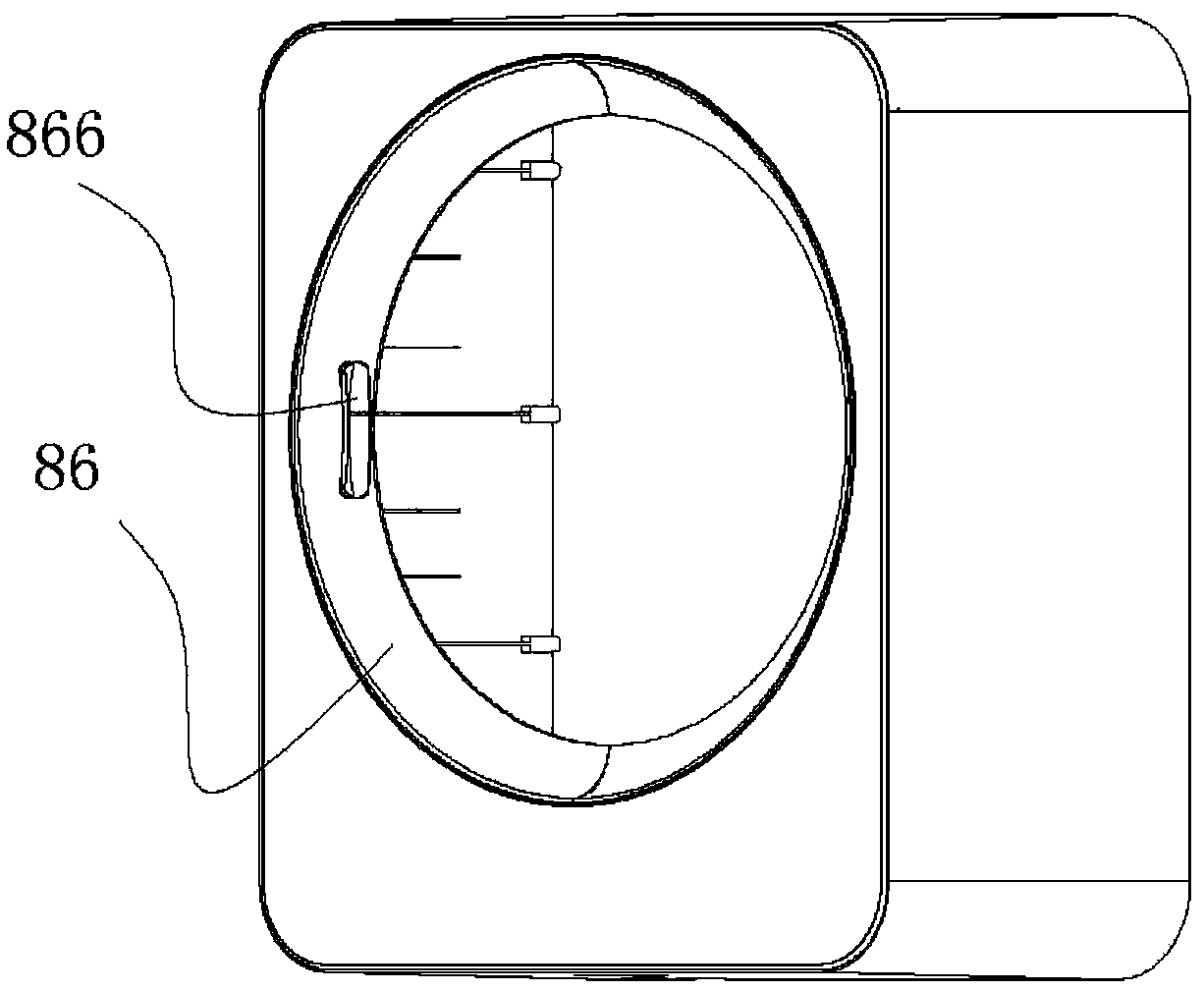

[0053] Such as Figure 1 to Figure 9 As shown, the difference between the wall-mounted laundry processing equipment in this embodiment and the above-mentioned embodiments is that: the front assembly assembly 860 includes a vacancy 866 allowing part of the hinge 72 to pass through, and part of the hinge 72 to pass through The vacant portion 866 is connected to the door body 6 . As a component with a certain function of modifying the clothes inlet, the front assembly component is set on the outermost side of the clothes inlet facing the outside of the device. Setting a vacant part at this position can realize the concealment of the hinge and will not damage the integration of the device. sex. The vacant portion 866 is disposed through the front assembly component 860 , and at least part of the vacant portion 866 is a hole-like structure. In this embodiment, the size of the vacant portion should be sufficient for the movable end to move flexibly. The movable end is connected w...

Embodiment 3

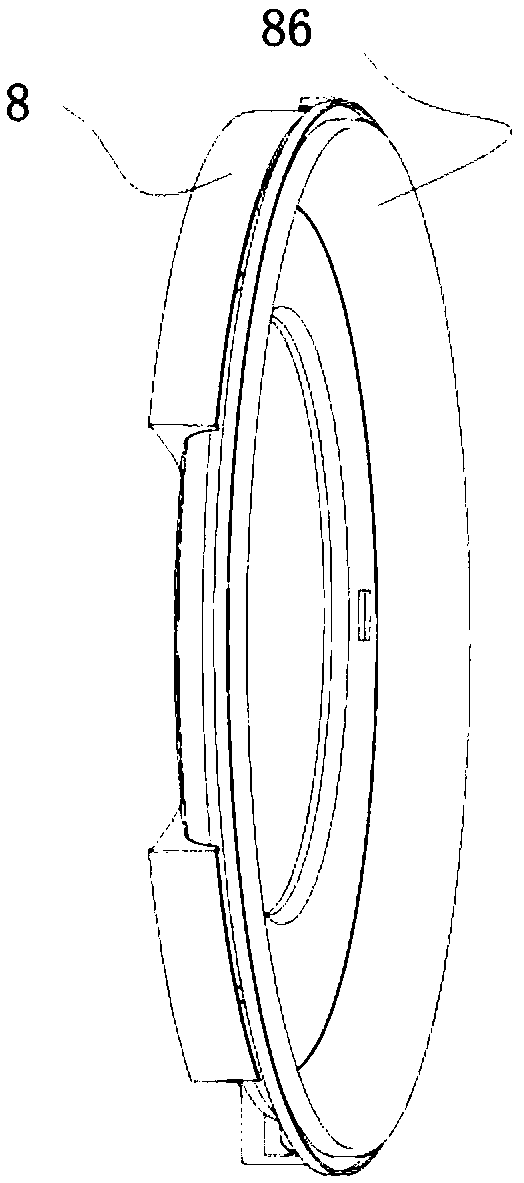

[0056] Such as Figure 1 to Figure 9 As shown, the difference between the wall-mounted laundry processing equipment described in this embodiment and the above-mentioned embodiments is that: the outer periphery of the assembly part 86 extends laterally away from the bottom of the bucket body 11, and the assembly part 86 extends along the Its outer peripheral side forms a slope-like structure toward the inner peripheral side, such as Figure 5 shown. The slope-like orientation forms a certain angle with the axial direction of the barrel body 11 , and this angle is suitable for the space requirement of the movable end 722 of the hinge 72 which requires a certain angular range of motion.

[0057] Further, at least part of the hinge in this embodiment is disposed between the slope and the barrel. The slope-shaped structure can provide a certain space between the inclined surface of the slope and the barrel body, which can be used to hide most of the structure of the hinge and mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com