Method for treating low-tin materials through reverse expanding rotary kiln

A rotary kiln and material technology, applied in the field of non-ferrous metal metallurgy, can solve the problems of complex structure, difficult operation and large equipment investment, and achieve the effect of simple operation, less equipment failure and small investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

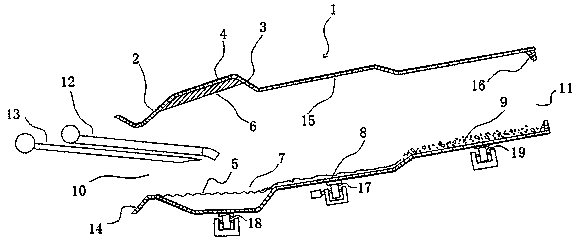

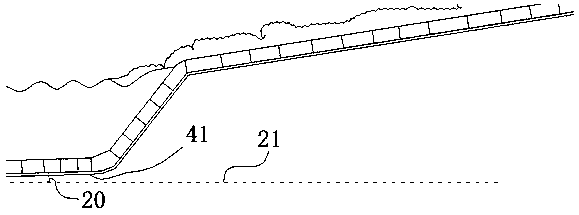

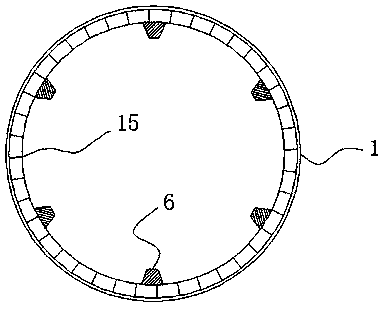

[0054] Example: such as figure 1 As shown, a reverse-expanding rotary kiln for processing low-tin materials includes a cylinder 1 arranged obliquely. The cylinder 1 is an inner hollow rotating body of the reverse-expanding rotary kiln. The front end is a kiln head port 10, and the rear The end is the kiln tail port 11, and the height of the kiln head port 10 is lower than the height of the kiln tail port 11. Between the kiln head port 10 and the kiln tail port 11 of the cylinder body 1, a reaction pool section 7 is arranged in sequence from front to back. , the melting section 8, the drying section 9; the reaction pool section 7 is composed of the front wall section 2, the bottom surface section 4 and the back wall section 3; The concave space is naturally formed, forming a molten reaction tank 5 with sufficient volume to accommodate the molten reaction materials and to allow the reaction materials to have sufficient reaction time here.

[0055] Due to the low manufacturing c...

experiment example 1

[0083] The zinc high-acid leaching slag containing 20% moisture, 2% Sn, and 4% Zn is mixed with anthracite according to 10% of the dry slag weight of the zinc high-acid leaching slag, and the mixed material is discharged from this site at a speed of 13.5t / h. The kiln tail port of the reverse-expanded rotary kiln described in the invention is continuously fed into the drying section of the rotary kiln. The outer diameter of the kiln tail port of the rotary kiln is 3.2m, the length is 0.3m, the average thickness of the steel plate of the cylinder is 40mm, and the thickness of the lining firebrick is 680mm; the outer diameter of the drying section is 3.2m, the length is 18m, the average thickness of the steel plate of the cylinder is 40mm, and the thickness of the lining firebrick is 300mm ; The outer diameter of the melting section is 3.6m, the length is 15m, the average thickness of the cylinder steel plate is 45mm, and the thickness of the lining refractory brick is 300mm; T...

no. 2 example

[0086] For the rich slag of Ausmelt furnace containing 7% Sn, anthracite is added according to 15% of the weight of the rich slag and mixed, and the mixed material is continuous from the kiln tail port of the reverse-expanded rotary kiln described in the present invention at a speed of 13.8t / h Added to the drying section of the rotary kiln. The outer diameter of the kiln tail port of the rotary kiln is 3.6m, the length is 0.3m, the average thickness of the steel plate of the rotary kiln shell is 45mm, and the thickness of the lining refractory brick is 720mm; The thickness of the brick is 350mm; the outer diameter of the melting section is 4.0m, the length is 18m, the average thickness of the cylinder steel plate is 50mm, and the thickness of the inner refractory brick is 350mm; the outer diameter of the bottom section is 4.5m, the length is 24m, the average thickness of the cylinder steel plate is 55mm, and the thickness of the inner refractory brick 420mm; the outer diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com