Racing-car anti-rolling annular overhead component

A component and annular technology, applied in the field of anti-roll ring overhead components of racing cars, can solve the problems of personal injury to the driver, the casing is easily concave to the inside to hurt the driver, the supporting force of the top component of the racing car is not strong enough, etc., and the effect of reducing the degree of damage is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

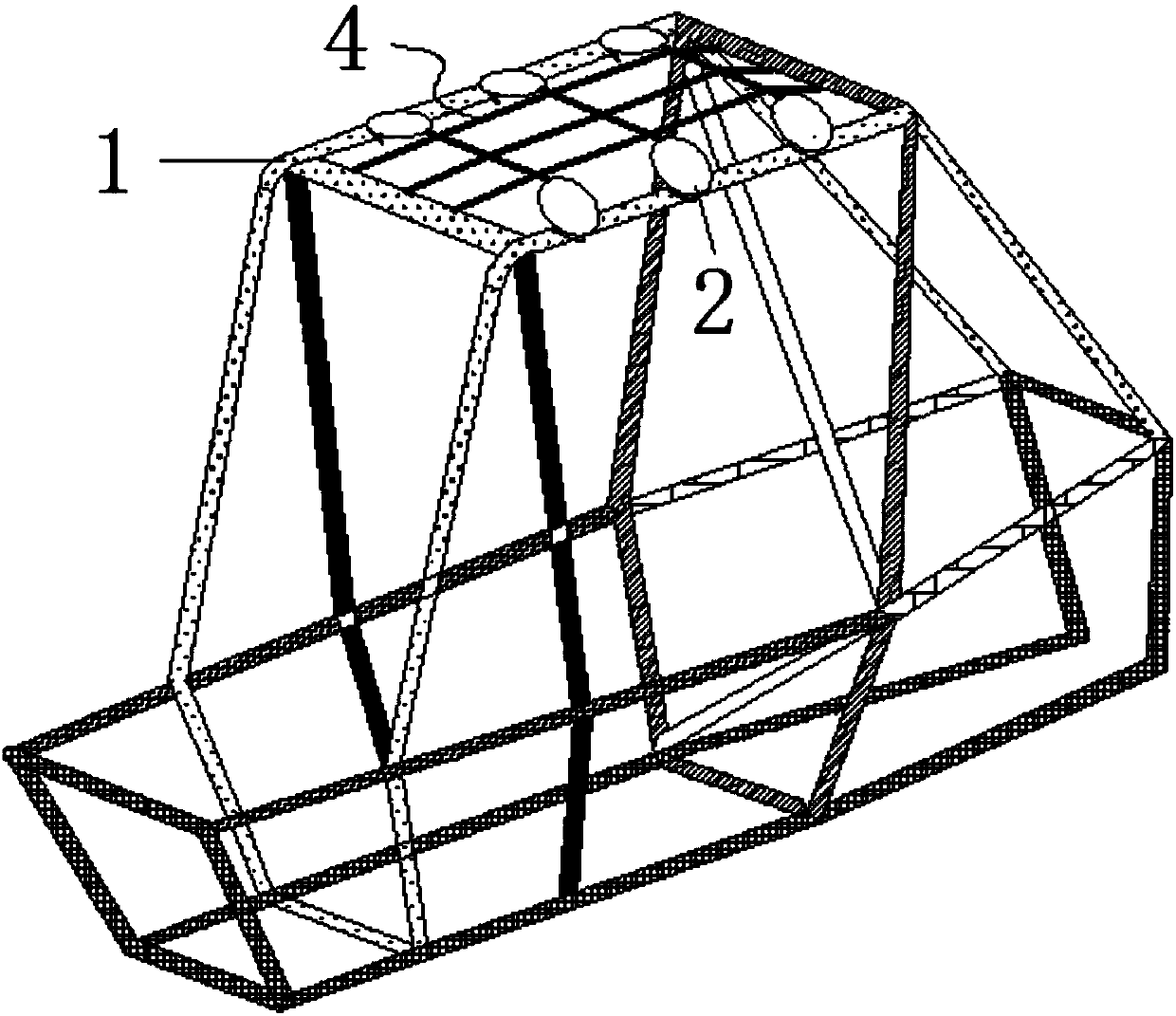

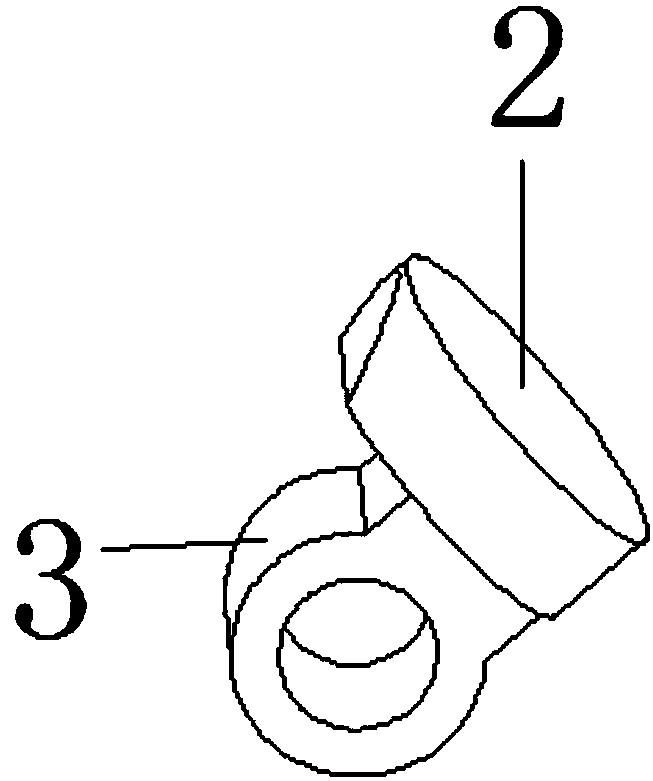

[0013] Such as figure 1 , figure 2 As shown, a racing car anti-rolling ring-shaped head member includes a racing car top member 1, a circular iron plate 2, a hollow cylinder type fixed block 3 and a steel bar 4, and is characterized in that: the racing car top member 1 is made of four steel pipes It is composed of welding, and the outer ends of the steel pipes on both sides are respectively symmetrically covered with three hollow cylindrical fixed blocks 3, and each hollow cylindrical fixed block 3 is welded with a ring-shaped iron plate 2, and the symmetrical ring-shaped iron plates on the steel pipes on both sides 2 are connected by welding of steel bars 4, three steel bars 4 are welded vertically to the top of the steel bars 4, and the two ends of the three steel bars 4 are respectively welded with the other two steel pipes of the top membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com