Heating and spinning flaring device

A technology of flaring dies and hydraulic cylinders, which is applied in the field of fork wheel hub processing devices, can solve the problems of fork wheel hub cracks, lower processing yields, and inability to obtain flare diameters, etc., to ensure service life, yield, and accuracy and the effect on the integrity of the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

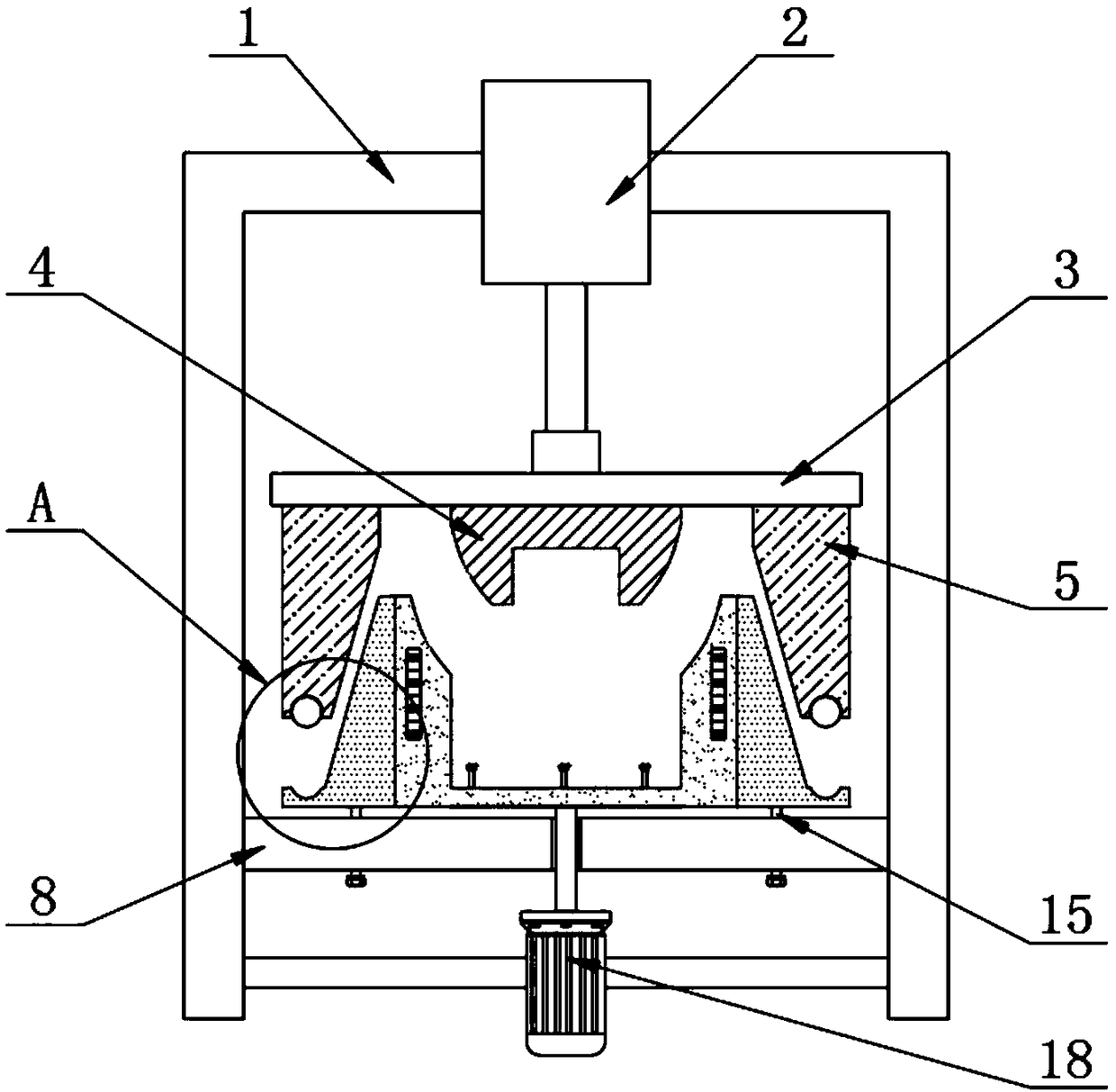

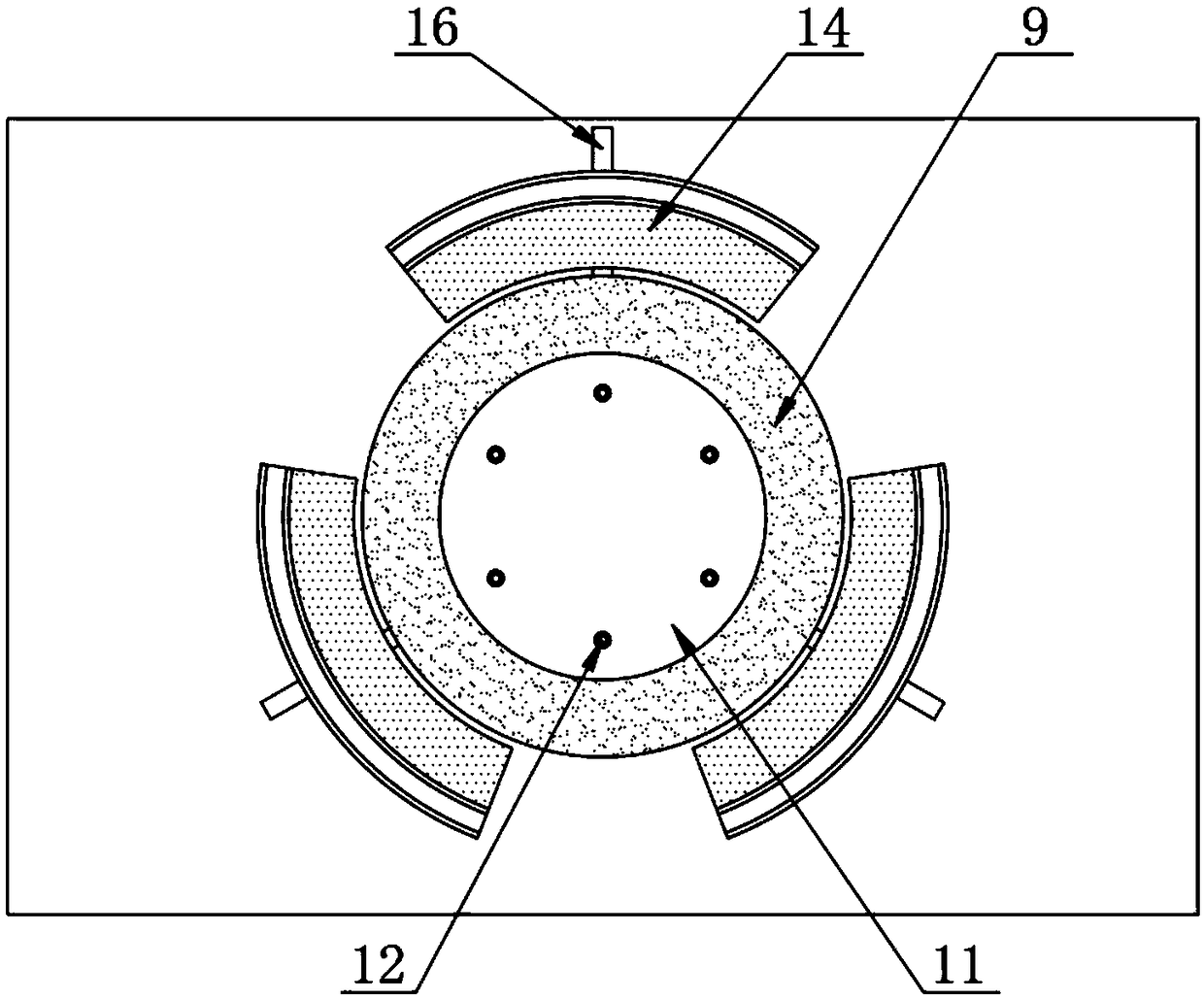

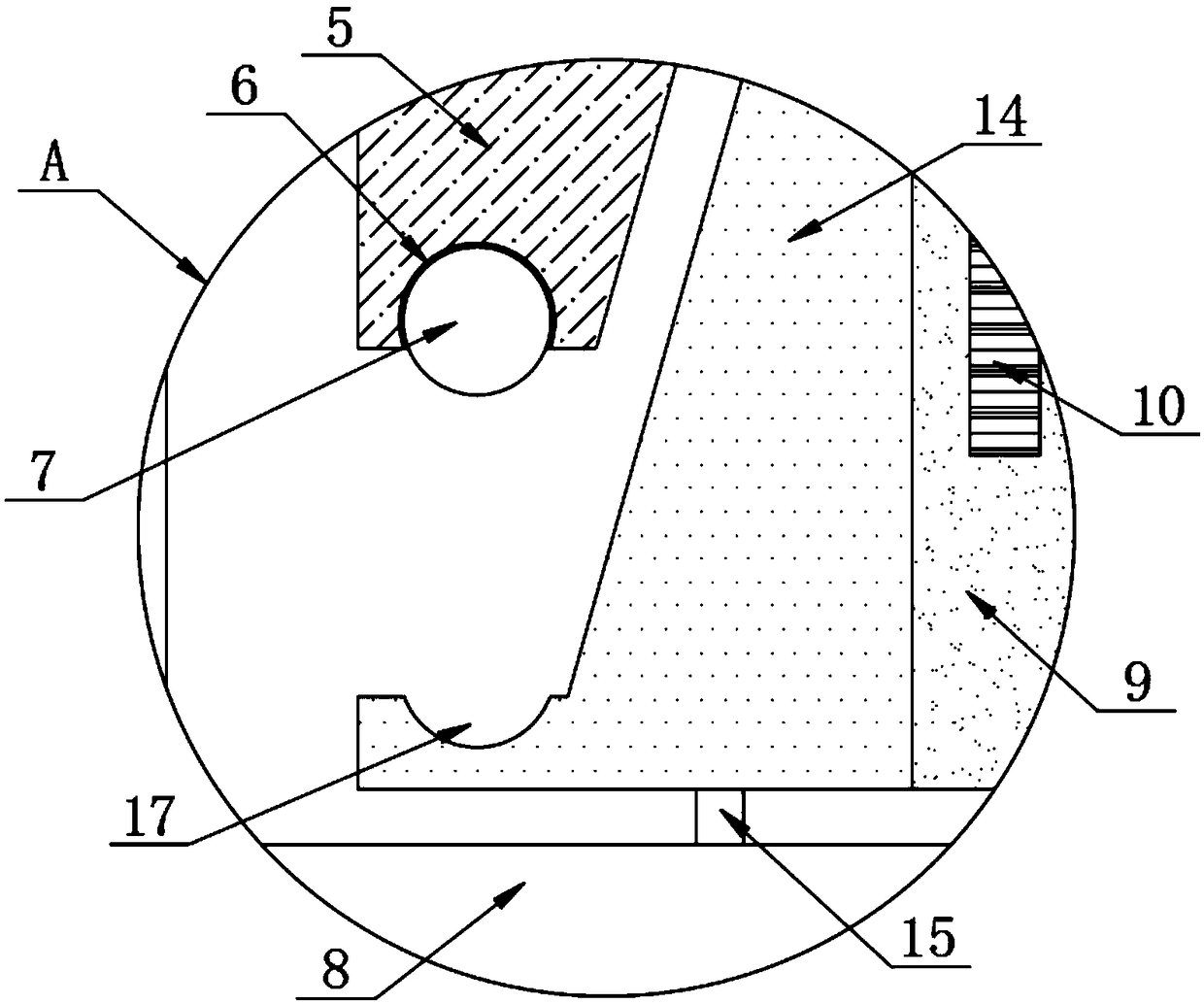

[0023] according to Figure 1-3 A heating spinning flaring device shown includes a main frame 1 and a hydraulic cylinder 2, the hydraulic cylinder 2 is arranged on the top of the main frame 1, and a movable plate 3 is provided at one end of the output shaft of the hydraulic cylinder 2, and the movable plate 3 is The bottom of the plate 3 is provided with a flaring die 4, and the outside of the flaring die 4 is provided with a positioning block 5, and the bottom end of the positioning block 5 is provided with a receiving groove 6, and the inside of the receiving groove 6 is provided with a ball 7. The bottom of the die 4 is provided with a fixed plate 8, and the top of the fixed plate 8 is provided with a movable plate 9, and the inside of the movable plate 9 is provided with a heating rod 10, and the inside of the movable plate 9 is provided with a flared mold groove 11. A first fixing bolt 12 is provided inside the flared die groove 11, a heat insulating layer 13 is provided ...

Embodiment 2

[0029] according to Figure 4 A kind of heating spinning flaring device shown, described flaring die 4 and positioning block 5 are fixedly connected with movable plate 3, and described flaring die 4 is matched with flaring die groove 11, and flaring die 4 When processing the fork wheel hub in the flared die groove 11, the opening groove at the top of the flared die groove 11 can be shaped, and prevent the flared die 4 from further penetrating into the flared die groove 11 to ensure that the processed forklift The precision of the hub and the integrity of the appearance;

[0030] The heat insulation layer 13 is fixedly connected with the outer wall of the movable plate 9, and the heat insulation layer 13 is made of rock wool material, and the heat insulation layer 13 of the rock wool material is provided to process the fork wheel hub in the flared die groove 11. The heat generated by the heating rod 10 is isolated to prevent the high temperature from being directly transmitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com