Adjustable soil shovel conveyor

A transporter and adjustable technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of vehicle operators' safety threats and inability to slide down by themselves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

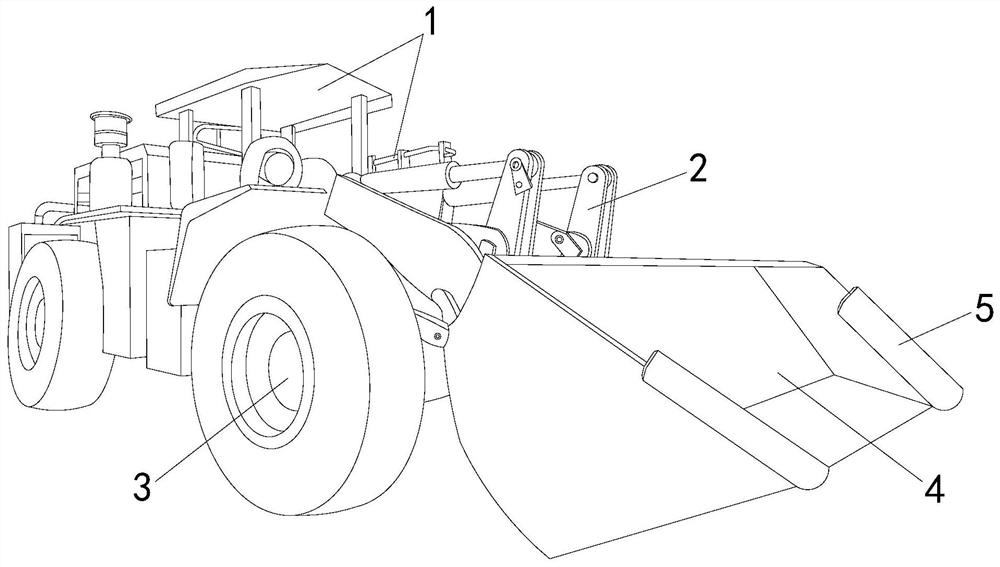

[0023] see figure 1 , the present invention provides an adjustable earth shovel transporter, the structure of which includes: frame 1, push rod arm 2, drive wheel 3, bucket 4, soil loosening mechanism 5, the front end of the frame 1 is connected to the push rod arm 2 And its bottom is provided with driving wheel 3 and is connected with it, bucket 4 is located at one end of push rod arm 2 and its both sides are provided with soil loosening mechanism 5, and frame 1 is the vehicle body structure of transporter, includes the vehicle body frame structure and the shelter of the top at the same time structure and power supply structure, the push rod arm 2 is the connection carrier between the frame 1 and the bucket 4, and is also a power component used to control the forward and backward retraction of the bucket 4. The height can realize the action of pushing and shoveling sand and soil and make the bucket 4 turn over at a specific angle by means of a certain angle. The driving whee...

Embodiment 2

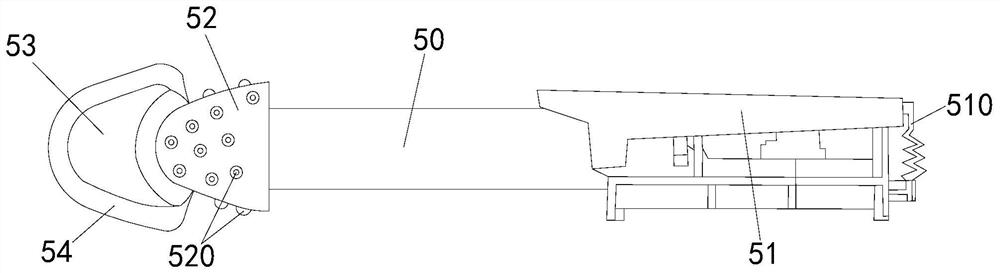

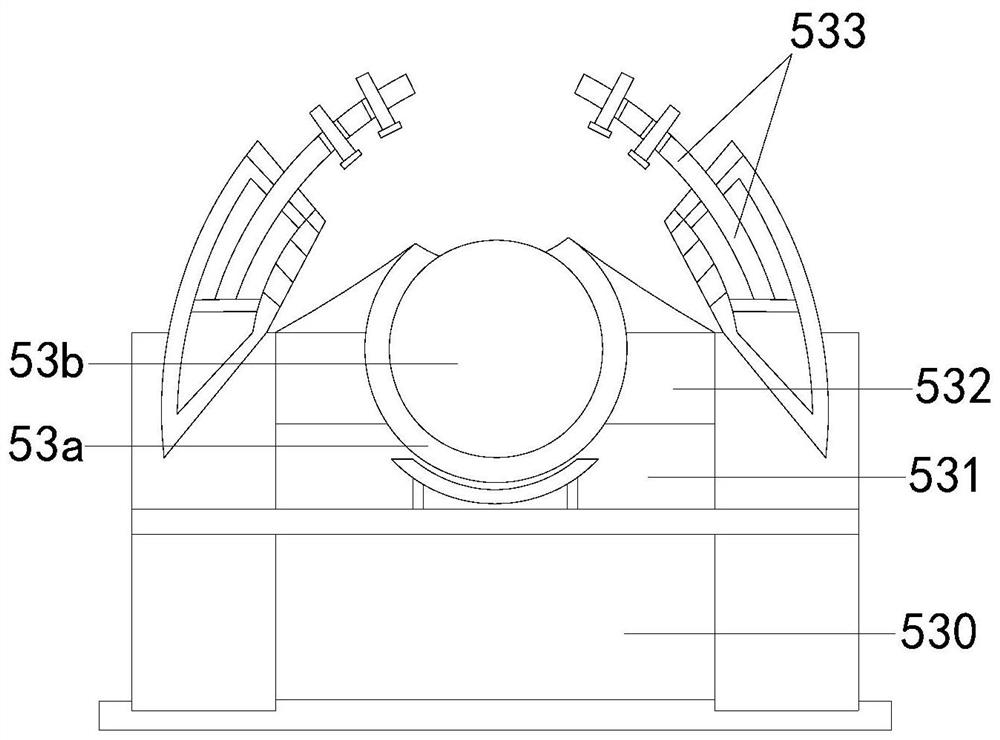

[0029] The description of the second embodiment drawn in conjunction with the first embodiment, combined with figure 2 , image 3 and Figure 4 The two ends of the slide rod 50 are respectively connected to the piston rod 51 and the drill bit 52, the top position of the drill bit 52 is connected to the push head 53 and a vibration bag 54 is arranged on the outside, the top of the socket 530 is connected to the ball seat 531, and the ball seat 531 is two A hook contactor 532 is provided on the side and a drill ring 533 is correspondingly provided above it, and a pressing block 5321 is provided on the base 5320, and a pressing block 5321 and a slot 5325 opened on the surface of the base 5320 are correspondingly provided with an extrusion Cone 5324 and extruding cone 5324 are connected to pressing frame 5322 through hook spring 5323. When bucket 4 just enters the range of sand and soil stacking, the drill ring 533 is driven by slide rod 50 to rotate at high speed to destroy the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com