Composite type fiber filtering material and preparation method thereof as well as filtering bag

A fiber filtration and composite technology, which is applied in the field of composite fiber filter materials and filter bags, can solve the problems of low efficiency and short service life, and achieve the effect of improving filtration efficiency, simple and convenient preparation method, and good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method for preparing the composite polyphenylene sulfide fiber filter material includes the following steps: making polyphenylene sulfide fibers, polytetrafluoroethylene fibers, meta-aramid fibers or polyimide fibers through acupuncture and heat setting steps. Form a support layer; transport the polyphenylene sulfide resin melt to the melt-blown die head, spray it out under the action of hot air at 300-380°C, and stretch it into a melt flow, and the melt flow adheres to the support layer The fiber web layer is formed on the upper layer; the fiber web layer and the support layer are combined through needle punching or hydroentangling processes to form a composite felt, and the PTFE film with a microporous structure is adhered to the fiber web layer by thermal bonding, and passed through a hot roller. Roll forming to form a composite polyphenylene sulfide filter material.

[0026] The needle punching density and depth of the needle punching step in the pro...

Embodiment 1

[0042] PPS staple fibers (length 5mm, fineness 2.2dtex) are opened, carded into a web, and laid into a web, and then laminated with PPS yarn base cloth and enter the pre-needling, second and The third needle-punching, and then heat-setting by tentering to become a PPS needle-punched felt (supporting layer), and the heat-setting temperature is 230°C. Then the needle felt plain felt will be pulled into the melt blown process.

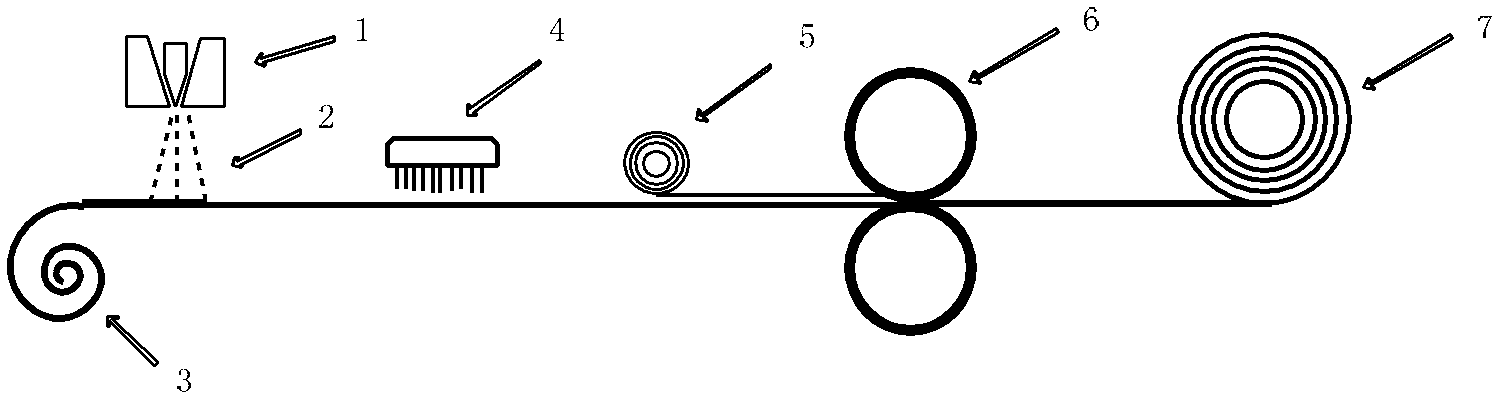

[0043] figure 1 A schematic diagram of the process flow of the composite filter material provided in this embodiment is shown. The device for preparing the composite type includes the following components: a melt-blown die head 1, a melt metering pump, a screw extruder, a high-pressure air heating device, a needle felt driving wheel, and a hot-rolled forming roll.

[0044] The polyphenylene sulfide resin is processed into a viscous fluid melt in a single-screw extruder, and the maximum temperature of the screw is 340°C (at 340°C, the melt temperature is...

Embodiment 2

[0051] PTFE fiber (length 51mm, fineness 3.0dtex) is opened, carded into a web, and laid into a web, and then laminated with PTFE yarn base cloth and enters the pre-needling and second needling , and then heat-set by tentering to become a PTFE needle-punched felt, and the heat-setting temperature is 250°C. Then the needle felt plain felt will be pulled into the melt blown process.

[0052] figure 1 A schematic diagram of the process flow of the composite filter material provided in this embodiment is shown. The device for preparing the composite type includes the following components: a melt-blowing die head 1, a melt metering pump, a screw extruder, a high-pressure air heating device, a needle felt driving wheel 5, and a hot rolling forming roll 6.

[0053] The polyphenylene sulfide resin is processed into a viscous fluid melt in a single-screw extruder, and the maximum temperature of the screw is 340°C (at 340°C, the melt temperature is 1.5×10~2.5×10 3 sec -1 The shear v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com