Whole-granule wet-process mixing granulator

A wet mixing and granulator technology, which is applied in the methods of granulating raw materials, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of reducing the overall equipment use effect, accumulation of equipment dead corners, and insufficient airtightness. , to avoid material leakage or human contact hazards, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

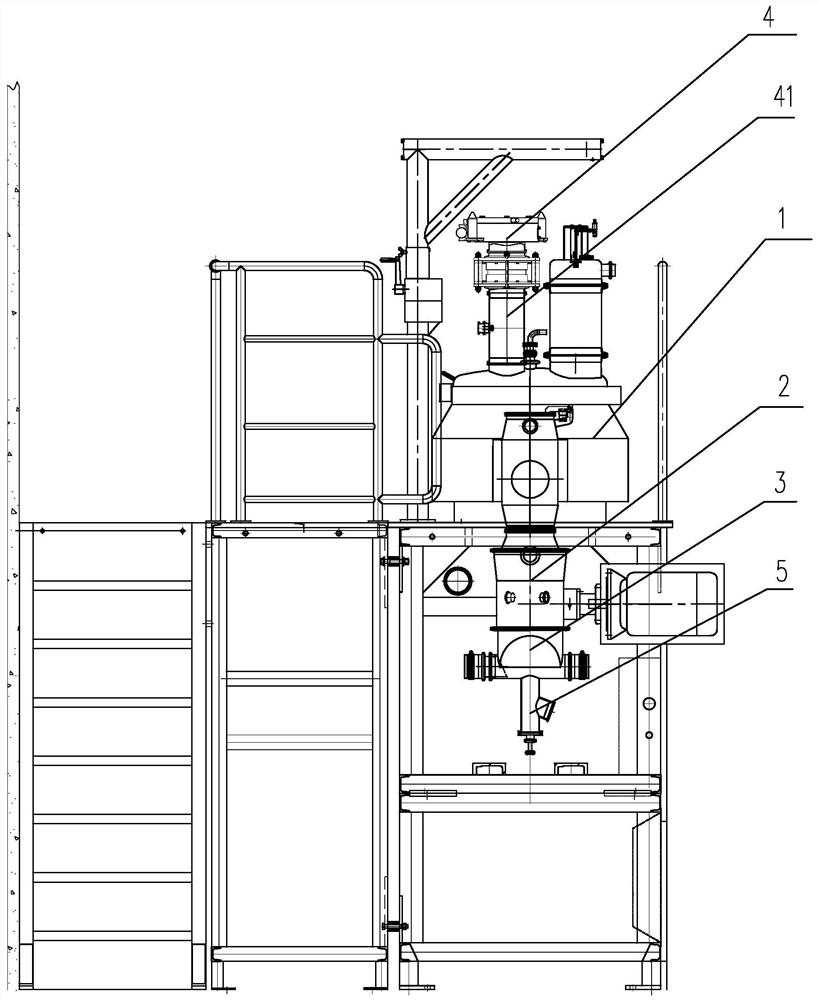

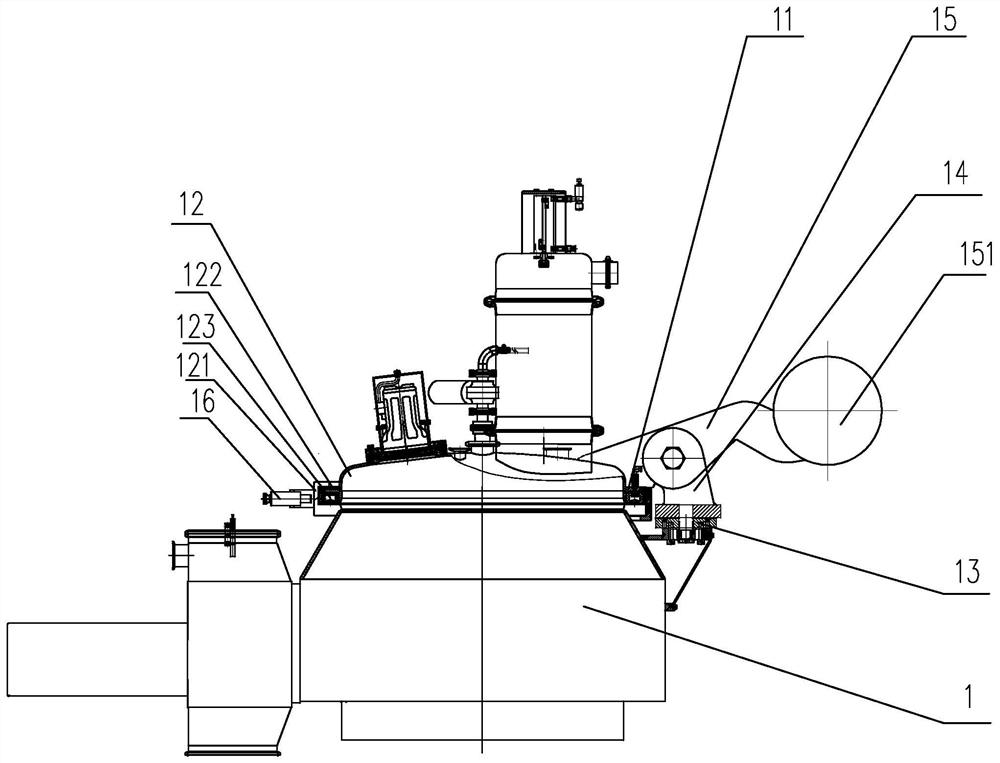

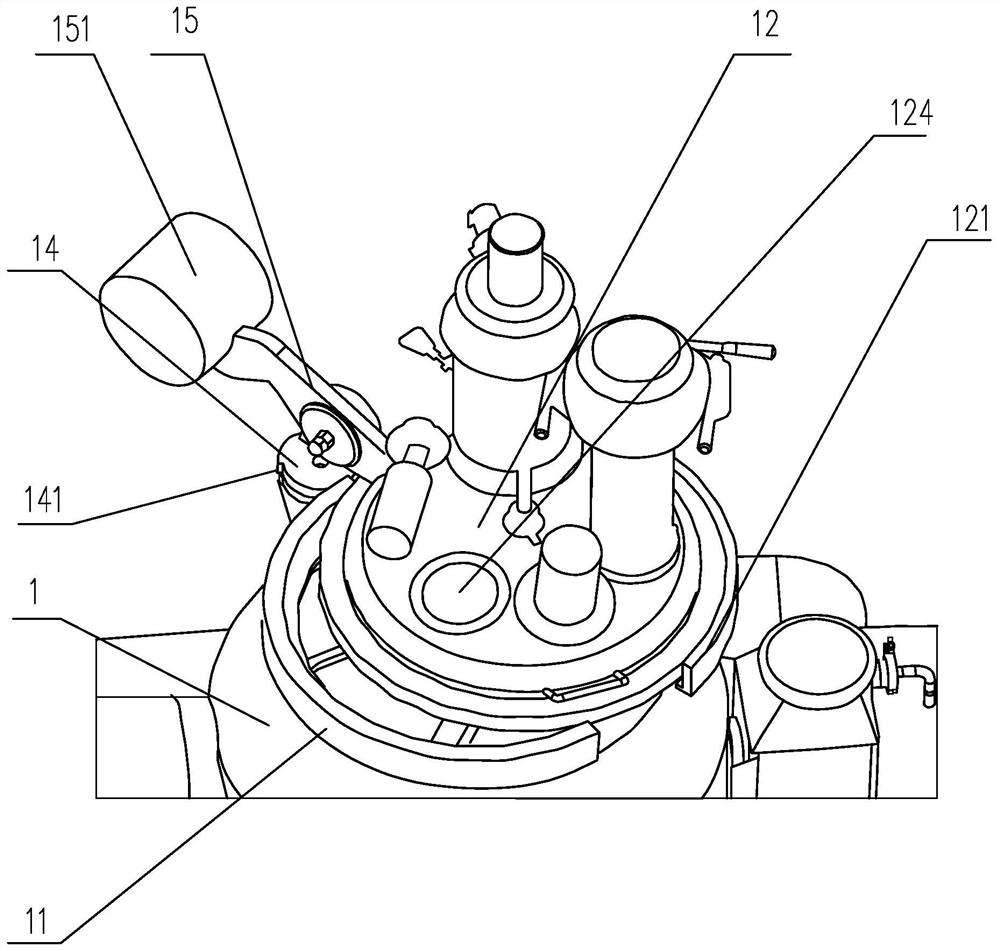

[0026] The embodiment of the granulation wet mixing granulator of the present invention is for example Figure 1 to Figure 6As shown: it includes material cylinder 1, granulator 2 and discharger 3 arranged in sequence from top to bottom. The material cylinder 1, granulator 2 and discharger 3 are connected and arranged. There is a cylinder cover 12, the cylinder cover 12 is provided with a feed pipe 41, the end of the feed pipe 41 is connected with an αβ valve 4, and a turntable 13 is arranged on one side of the feed cylinder 1, and the turntable 13 rotates A connecting seat 14 is provided, and the cylinder head 12 is hinged with the connecting seat 14 through a swing rod 15. The cylinder head 12 is provided with a positioning retaining ring 121 along the circumference, and the material cylinder 1 is provided with a Interference retaining ring 11, the positioning retaining ring 121 is combined with the resisting retaining ring 11 to form a surround on the opening position, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com