Environment-friendly recycled fine sand

An environment-friendly, fine sand technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of not conforming to the habit of using ready-mixed mortar, coarse particle size, not good enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, the preparation of environment-friendly regenerated fine sand

[0046] Prepare environment-friendly regenerated fine sand of the present invention according to the following steps:

[0047] A. Dispose of construction waste through pretreatment equipment to obtain materials with a particle size of 5mm≤particle size≤50mm;

[0048] Specifically, the construction waste is first roughly crushed, and the construction waste is roughly crushed to a material with a particle size of about 100mm by using crushing equipment (jaw crushing, impact crushing, roller crushing or hammer crushing); then the plastic, fabric, wood and the like in the construction waste are Light combustibles are sorted and removed manually or mechanically; then crushing equipment (impact crushing or coarse hammer crushing) is used to achieve medium crushing of construction waste coarse materials; at the same time, due to the low strength of the soil in construction waste, the high-speed rotati...

Embodiment 2

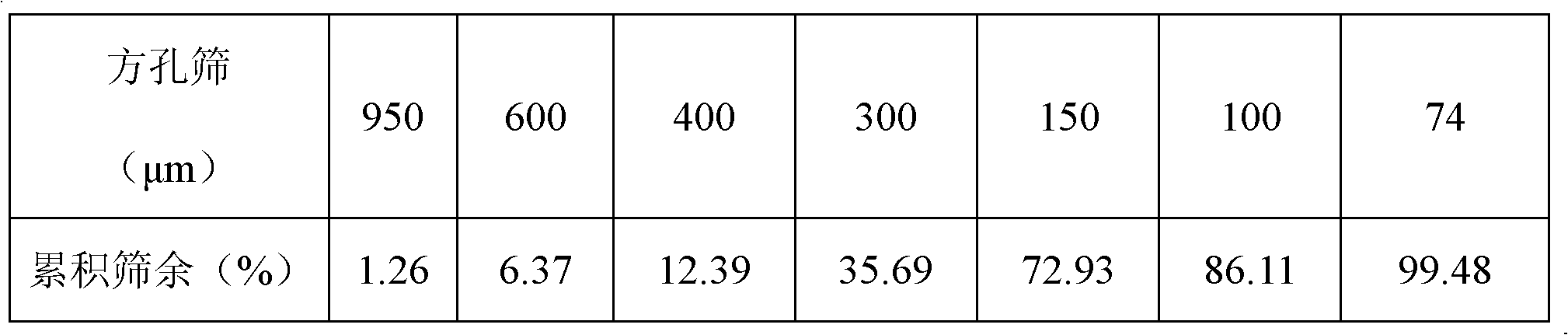

[0053] Example 2 , Environmentally friendly recycled fine sand detection

[0054] As shown in Table 1, take 2000 g of fine sand with a size of 80 μmm≤particle size≤1000 μm in Example 1, and use a negative pressure sieve analyzer to screen with square hole sieves with different apertures, and measure the weight percentage of the cumulative sieve residue.

[0055] Table 1

[0056]

[0057] Referring to the test method in "GBT 25176-2010 Recycled Fine Aggregate for Concrete and Mortar", various properties of fine sand were measured, and the results are shown in Table 2:

[0058] Table 2

[0059] project

[0060] alkali aggregate reaction

[0061] From the results in Table 2, it can be seen that the environment-friendly recycled fine sand of the present invention meets the standard of "Recycled Fine Aggregate for Concrete and Mortar" (GBT 25176-2010) after testing.

Embodiment 3

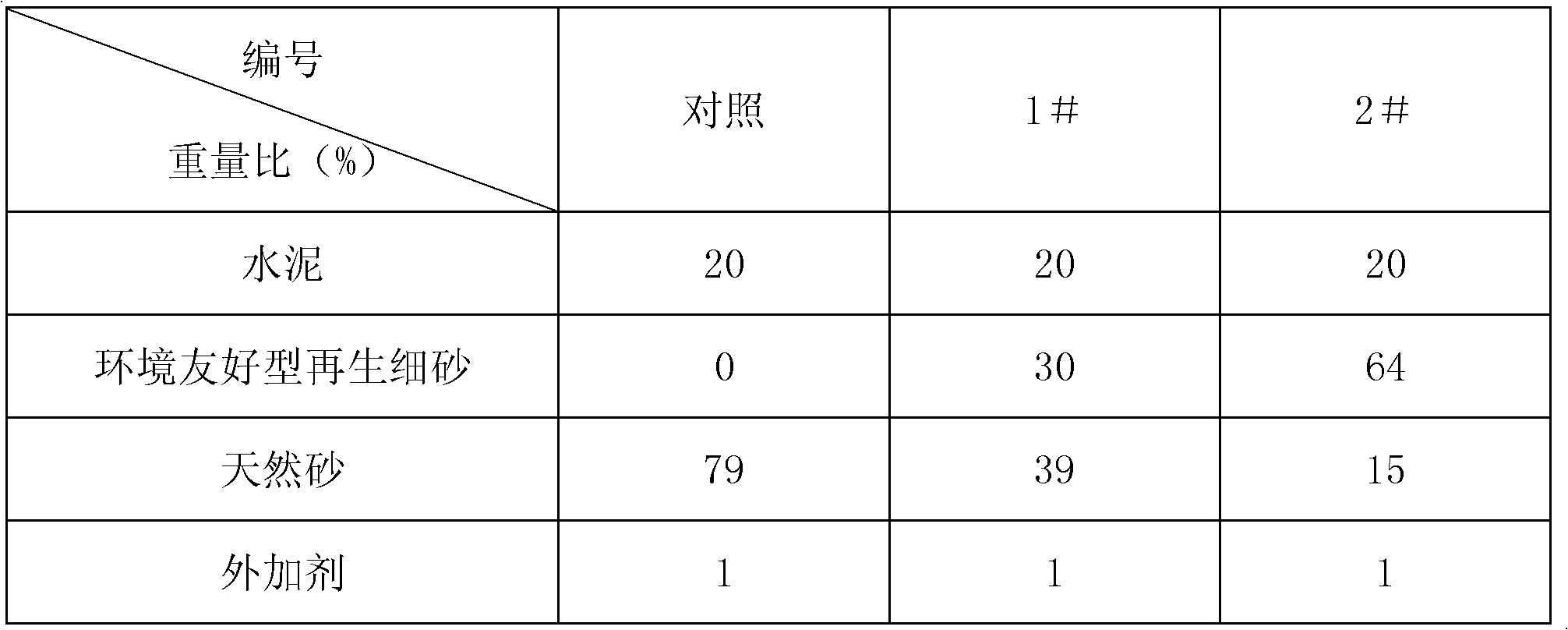

[0062] Example 3 , Application of environment-friendly recycled fine sand

[0063] According to the formula shown in table 3, the environment-friendly regenerated fine sand of the present invention is normally produced masonry mortar according to normal ready-mixed mortar (or dry mortar or wet mortar).

[0064] table 3

[0065]

[0066] Take the mortar in Table 3, add appropriate amount of water to the standard consistency of 90mm, and test according to "GBT 25176-2010 Recycled Fine Aggregate for Concrete and Mortar". The results are shown in Table 4:

[0067] Table 4

[0068]

control

1#

2#

Consistency (mm)

92

89

88

28-day compressive strength (MPa)

15.9

13.2

11.2

[0069] As can be seen from Table 4, the environment-friendly regenerated fine sand of the present invention can partially or completely replace natural sand, and can produce masonry mortar that meets the label requirements.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com