Preparation method of anti-aging agent 264

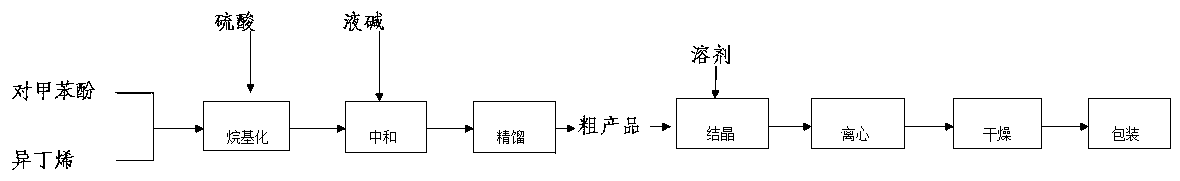

An anti-aging agent and crystallization technology, which is applied in the field of preparation of anti-aging agent 264, can solve the problems of increasing tar discharge, high energy consumption, and low single-pass yield, and achieves less dangerous waste liquid, small equipment investment, and single-pass yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

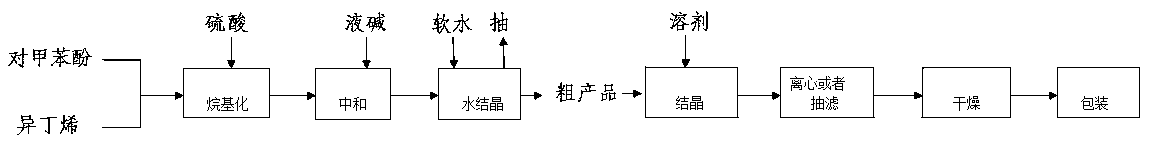

[0011] The preparation method that the present invention adopts sees figure 2 . The specific process is as follows:

[0012] First put p-cresol and concentrated sulfuric acid into the alkylation reaction kettle and pass through isobutylene to carry out the alkylation reaction. Neutralize with sodium hydroxide after the alkylation reaction. Then wash with water in the alkylation reaction kettle, and separate the water layer to obtain the anti-aging agent 264 mother liquor. Add soft water to the anti-aging agent 264 mother liquor to carry out water crystallization and separate the crude product. The crude product is then crystallized, centrifuged, filtered, and dried to obtain antiaging agent 264.

[0013] Among them, the operating conditions of water crystallization: the amount of soft water added is 0.85-2.5 of the volume of the anti-aging agent 264 mother liquor, the crystallization temperature is 40-80 ° C, the stirring speed is 30-50 rpm, the upper layer after standing...

Embodiment 1

[0016] First put 100Kg of p-cresol and 0.3Kg of concentrated sulfuric acid into the alkylation reactor and feed 120Kg of isobutylene to carry out the alkylation reaction. After the alkylation reaction, neutralize with sodium hydroxide to pH=7. Then wash with water in the alkylation reaction kettle, and separate the water layer to obtain the anti-aging agent 264 mother liquor. Add soft water to the anti-aging agent 264 mother liquor to carry out water crystallization and separate the crude product. The crude product is then crystallized, centrifuged, filtered, and dried to obtain antiaging agent 264.

[0017] Among them, the operating conditions for water crystallization: the amount of soft water added is 0.85 of the volume of the anti-aging agent 264 mother liquor, the crystallization temperature is 40-80 ° C, the stirring speed is (30-50) rpm, the upper layer after standing and stratifying is the oil phase, and the oil phase is used Extraction and concentrated treatment, th...

Embodiment 2

[0020] First put 100Kg of p-cresol and 0.3Kg of concentrated sulfuric acid into the alkylation reactor and feed 120Kg of isobutylene to carry out the alkylation reaction. After the alkylation reaction, neutralize with sodium hydroxide to pH=7. Then wash with water in the alkylation reaction kettle, and separate the water layer to obtain the anti-aging agent 264 mother liquor. Add soft water to the anti-aging agent 264 mother liquor to carry out water crystallization and separate the crude product. The crude product is then crystallized, centrifuged, filtered, and dried to obtain antiaging agent 264.

[0021] Among them, the operating conditions for water crystallization: the amount of soft water added is 1.5 of the volume of the anti-aging agent 264 mother liquor, the crystallization temperature is 40-80°C, the stirring speed is (30-50) rpm, the upper layer after standing and stratifying is the oil phase, and vacuum Extraction and concentrated treatment, the lower layer is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com