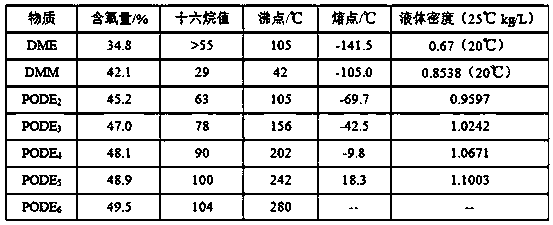

Adjustable hydrophilic and hydrophobic catalyst for preparation of polymethoxydimethyl ether as well as preparation method and application thereof

A technology of polyoxymethylene dimethyl ether and catalyst, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of reaction optimization, separation optimization, and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

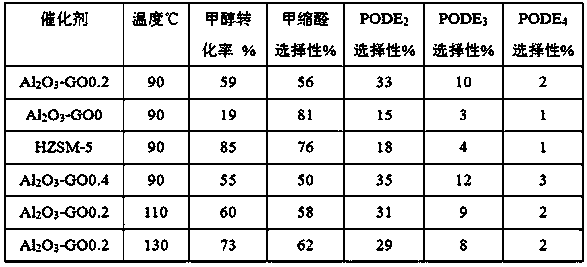

Embodiment 1

[0037] First, weigh 0.2g of graphene oxide, disperse it into 50ml of ethanol solution, and stir it. In order to better disperse it in the solution, place the suspension in an ultrasonic disperser for ultrasonic dispersion for 15 minutes; weigh 37.5g of Aluminum nitrate in water was dissolved in 50ml deionized water at 60°C, mixed with the dispersed graphene oxide-ethanol suspension, placed in an ultrasonic disperser for ultrasonic dispersion for 15 minutes, and then placed in a water bath at a constant temperature of 60°C for static After standing for 4 hours, put it in a blast drying oven at 120°C for 12 hours to evaporate the moisture remaining in the impregnated product. Finally, under the protection of nitrogen, the heating rate was controlled at 2 °C / min, and the temperature was gradually increased to 400 °C, and the calcined catalyst was kept for 4 h. The product taken out is a graphene-supported alumina catalyst, the mass ratio of the carrier to the active component is ...

Embodiment 2

[0042]Select the unsupported activated alumina of the catalyst and name it as Al 2 o 3 -GO0, for comparison.

[0043] Catalyst evaluation is the same as in Example 1.

[0044] The result of the reaction is that the conversion rate of methanol is 19%, the selectivity of methylal is 81%, and the PODE 2 15% selectivity, PODE 3 3% selectivity, PODE 4 The selectivity is 1%.

Embodiment 3

[0046] Catalyst HZSM-5 was chosen as a comparison.

[0047] Catalyst evaluation is the same as in Example 1.

[0048] The result of the reaction is that the conversion rate of methanol is 85%, the selectivity of methylal is 76%, and the PODE 2 18% selectivity, PODE 3 4% selectivity, PODE 4 The selectivity is 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com