Process for producing high yield methyl isocyanate

A technology of methyl isocyanate and production process, which is applied in the field of production technology for improving the yield of methyl isocyanate monomer, can solve problems such as unfavorable production of methyl isocyanate, high cost, complexity, etc., achieves a friendly natural environment, reduces labor intensity, The effect of inhibiting self-aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

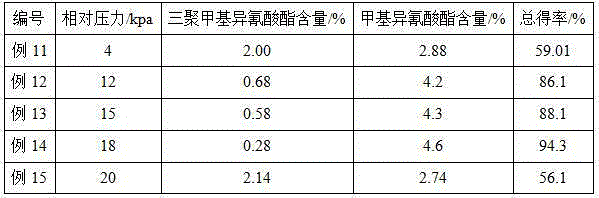

[0014] In the conventional production process of heating methylcarbamoyl chloride solution in a decomposer to decompose and generate methyl isocyanate, it is generally believed that the molecular weight of methyl isocyanate is small and difficult to polymerize, and it is generally believed that the polymerization inhibitor is only good for polymers with relatively large molecular weights. Therefore, no one in the prior art has tried to use a polymerization inhibitor in the process of heating carbamoyl chloride solution to decompose and generate methyl isocyanate. The inventor unexpectedly discovered in the experiment that adding a polymerization inhibitor under specific conditions can effectively reduce the formation of methyl isocyanate trimer, prevent process pipeline blockage, and help ensure the continuity of production and reduce production costs.

[0015] The technical solutions of the present invention will be further described below in conjunction with examples and comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com