A kind of method for preparing pseudoionone

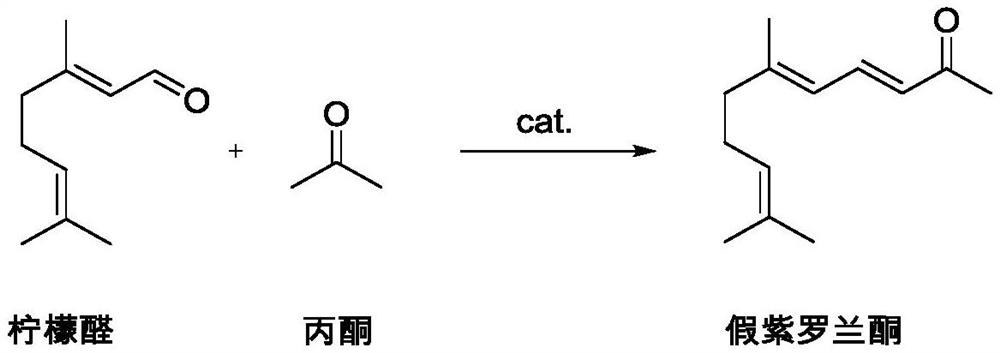

A technique for pseudo-ionone and acetone, which is applied in the field of preparing pseudo-ionone, can solve the problems of low yield, high toxicity and corrosiveness of the reaction solution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

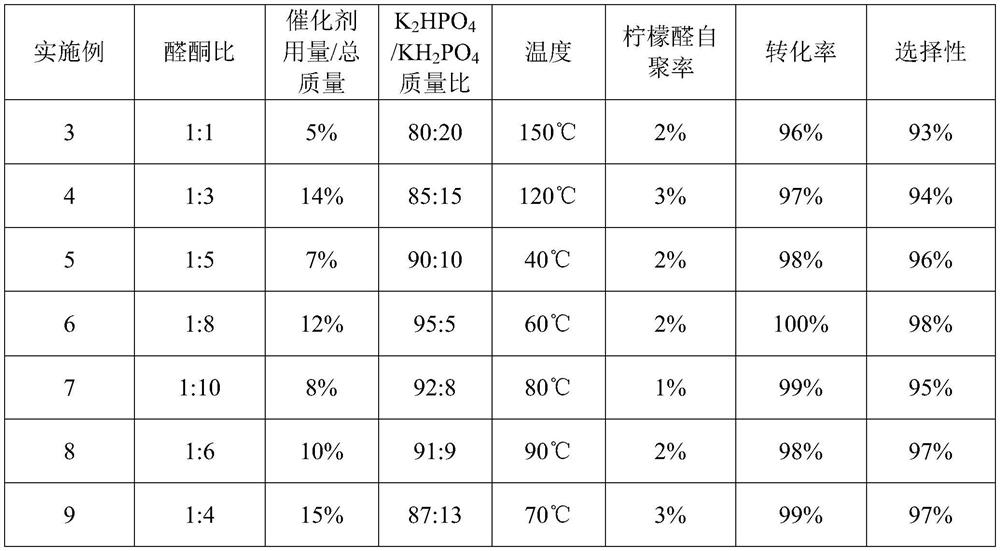

Examples

Embodiment 1

[0038] The preparation of embodiment 1 catalyst

[0039] Will K 2 HPO 4 (5.60g) and KH 2 PO 4 (0.41g) mixed, slowly added 9994.00g of deionized water to dilute, stirred for 1h until uniformly mixed, and obtained a phosphate catalyst solution. Its composition is: K 2 HPO 4 0.056wt%, KH 2 PO 4 0.0041wt%, H 2 O99.94wt%; pH7.8.

[0040] Embodiment 2 citral condensation reaction

[0041] Add citral (0.1mol, 15.22g), acetone (0.5mol, 29.04g), 4.91g of the phosphate catalyst solution prepared in Example 1 into a 250.0mL three-necked flask, double row pipe nitrogen replacement protection, stir with a magnet , turn on the condensate water, reflux the condensing tube, heat up to 60.0°C of the reaction solution, reflux the condensing tube for 3 hours, and maintain normal pressure during the reaction. After the reaction was completed, the temperature was lowered and the liquid was separated to obtain the reaction product. The reaction products were qualitatively analyzed by ...

Embodiment 10

[0046] Embodiment 10 Catalyst recovery applies mechanically

Embodiment 2

[0047] In Example 2, the reaction solution was poured into the separatory funnel and left to stand for 30min, separated and reclaimed the lower floor water phase catalyst, the pH of the reclaimed phosphate catalyst solution was 7.2, adding K 2 HPO 4 Adjust the pH to 7.8 to obtain a phosphate catalyst solution.

[0048] Add citral (0.1mol, 15.22g), acetone (0.5mol, 29.04g), and 4.91g of the above-mentioned phosphate catalyst solution into a 250.0mL three-necked flask, protect it by nitrogen replacement with a double row tube, stir with a magnet, and open the condensed water , the condensing tube was refluxed, the temperature was raised to 60.0° C. of the reaction liquid, the condensing tube was refluxed for 3 hours, and normal pressure was maintained during the reaction. After the reaction was completed, the temperature was lowered and the liquid was separated to obtain the reaction product. The reaction products were qualitatively analyzed by chromatography-mass spectrometer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com