A kind of preparation method of iron-nickel battery negative electrode material

An iron-nickel battery and negative electrode material technology, applied in nickel batteries, battery electrodes, alkaline battery electrodes, etc., can solve the problems of self-discharge, poor negative rate performance, low gram capacity, etc., and achieve lower electrode impedance and high gram capacity. , the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

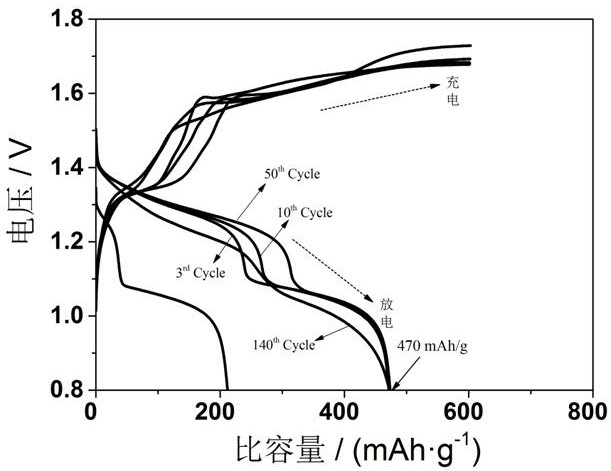

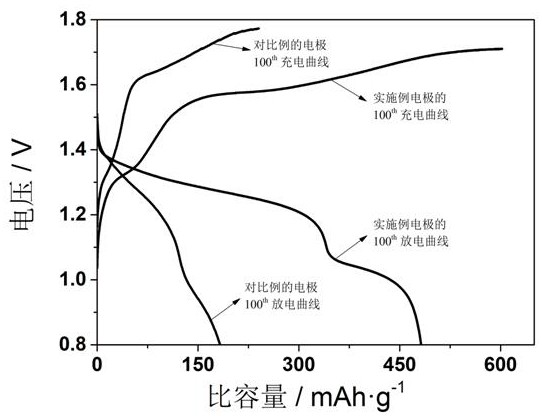

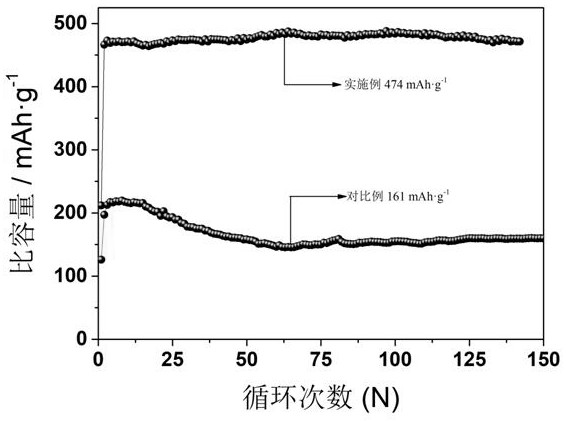

[0025] Add 0.5 g of carbon nanotubes, 1.0 g of graphene, 3.6 g of calcium hydroxide, and 93 g of nano-ferric oxide powder into 100.0 g of water, stir to form a uniform suspension, and then pass in carbon dioxide to carry out the reaction at 60°C. Gas-solid reaction, until the pH value of the suspension drops to 7, stop the ventilation, filter with suction, and wash to obtain 135 g of composite nanomaterial filter cake of calcium carbonate-loaded carbon nanotubes, graphene and ferroferric oxide.

[0026] Dissolve 0.3 g of hydroxyethyl cellulose in 15 g of water to make a 2 wt% aqueous solution of hydroxyethyl cellulose.

[0027] The above hydroxyethyl cellulose aqueous solution was added to 135 g of composite material filter cake, and then 13 g of water was added to obtain a slurry with a certain viscosity, and its solid content was determined to be 60 wt %.

[0028] Apply the above slurry evenly on the copper grid, and then put it in a vacuum drying oven. The temperature condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com