Preparation method of methomyl

A technology of methomyl and methylthioacetaldoxime, which is applied in the field of methomyl preparation, can solve problems such as equipment blockage, increased cost and difficulty of three waste treatment, and influence on normal production of the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

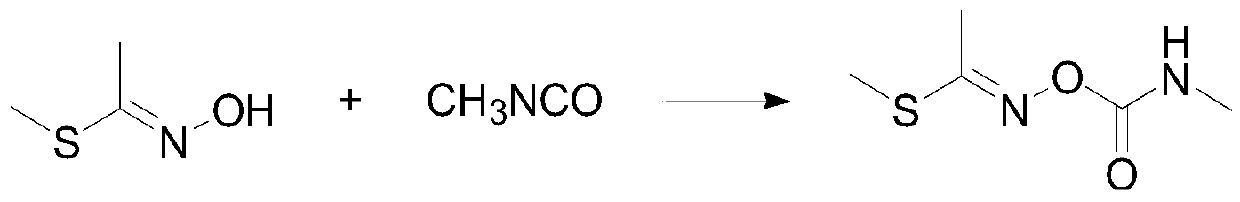

[0027] A preparation method of methomyl of the present invention comprises the following steps:

[0028] Add 107.16g (98.13%, 1mol) methylthioacetaldoxime, 0.33g (99%, 0.001mol) tetrabutylammonium bromide and 214.32g water to a 1000mL three-necked flask successively, drop 58.39g after cooling to 15°C (99.64%, 1.02mol) methyl isocyanate, after the dropwise addition, keep warm for 0.5h. After the reaction is completed, the temperature is raised to 50-60°C, the material is completely dissolved, cooled and crystallized, filtered, the filtrate is extracted with 85.73g of dichloromethane, and then precipitated, the precipitated solid is combined with the filter cake, and then dried in a vacuum oven at 50°C After drying for 12 hours, 160.56 g of white crystalline methomyl product was obtained, with a content of 98.5% and a yield of 97.5%.

Embodiment 2

[0030] A preparation method of methomyl of the present invention comprises the following steps:

[0031] Add 107.16g (98.13%, 1mol) methylthioglyoxaldoxime, 1.42g (98%, 0.005mol) tetrabutylammonium chloride and 321.48g water successively into a 1000mL three-necked flask, drop the temperature to 25°C and add 59.54g (99.64%, 1.04mol) methyl isocyanate, after the dropwise addition, keep warm for 1 hour. After the reaction was completed, the temperature was raised to 50-60°C, the material was completely dissolved, cooled and crystallized, filtered, the filtrate was extracted with 53.58g of chloroform, the precipitated solid was combined with the filter cake, and then dried in a vacuum oven at 50°C for 12 hours to obtain 161.37g white crystal methomyl product, content 98.21%, yield 97.7%.

Embodiment 3

[0033] A preparation method of methomyl of the present invention comprises the following steps:

[0034] Add 107.16g (98.13%, 1mol) methylthioacetaldoxime, 0.17g (99%, 0.0005mol) tetrabutylammonium bisulfate and 428.64g water in turn to a 1000mL three-necked flask, drop the temperature to 18°C and add 60.68g (99.64%, 1.06mol) methyl isocyanate, after the dropwise addition, keep warm for 0.5h. After the reaction, heat up to 50-60°C, cool and crystallize the material after complete dissolution, filter, extract the filtrate with 107.16g of methyl isobutyl ketone, combine the precipitated solid with the filter cake, and then dry it at 50°C in a vacuum drying oven After 12 hours, 162.71 g of white crystal methomyl product was obtained, with a content of 98% and a yield of 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com