Application method of methylamino formyl chloride decomposition tail gas hydrogen chloride in cartap synthesis

A technology of methylcarbamoyl chloride and an application method, which is applied in the synthesis of saquat, in the field of methylcarbamoyl chloride decomposing tail gas hydrogen chloride, can solve the problems of high energy consumption, high by-produced hydrochloric acid, large equipment investment, etc. The effect of less hydrochloric acid production, less equipment investment, and fewer preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

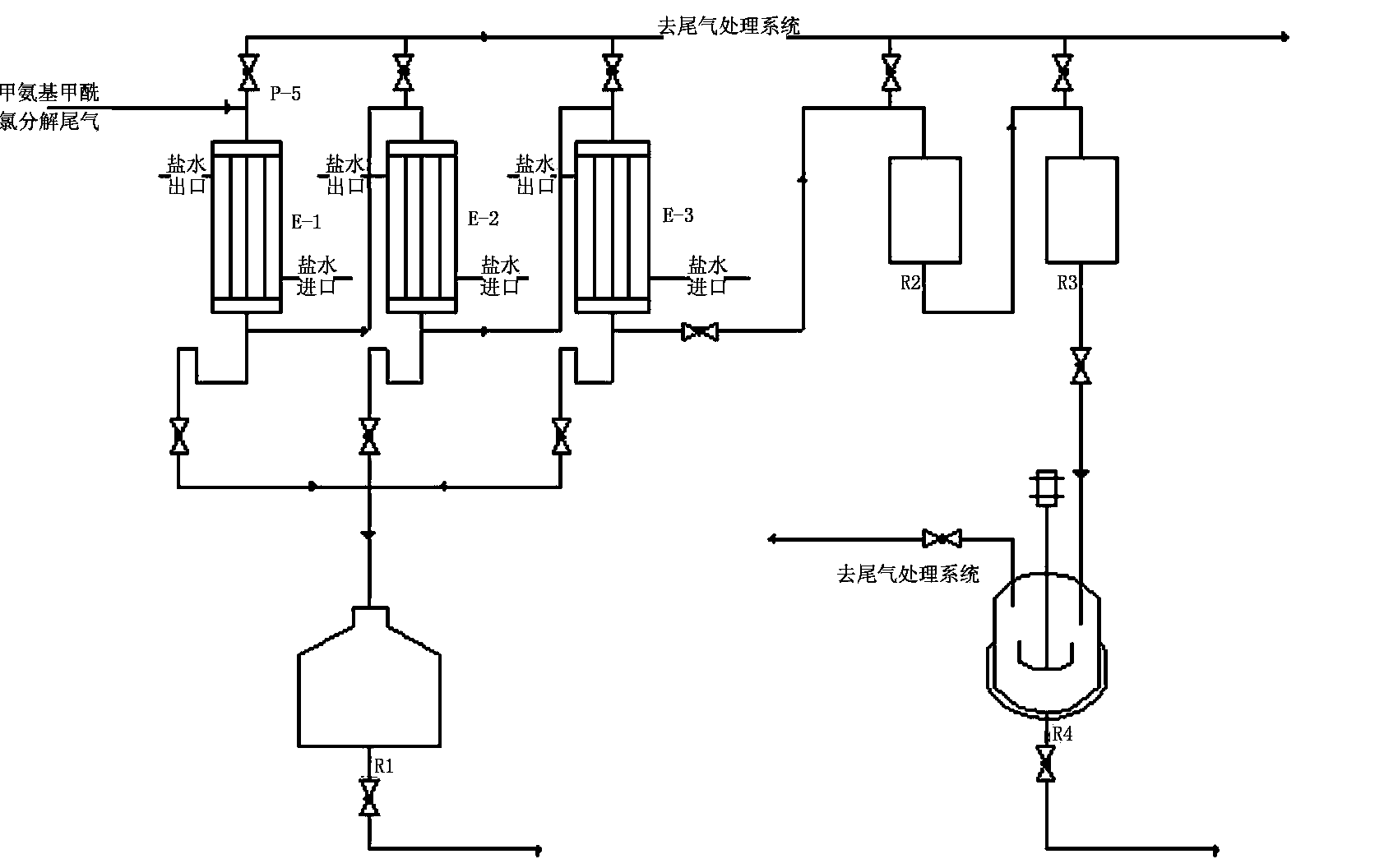

Image

Examples

Embodiment 1

[0018] Collect the mixed tail gas containing hydrogen chloride, chloroform and methyl isocyanate generated by the decomposition of carbamoyl chloride into the tail gas collection tank, and then condense through the condenser, and the condensed chloroform and methyl isocyanate condensate is transferred to methylamino The formyl chloride mixing tank enters the methyl isocyanate production system for recycling; the hydrogen chloride gas that has not been condensed is used to prepare cartap after being stabilized in the secondary buffer tank.

[0019] Add 346.0Kg of dichloroethane solution with a mass fraction of thiocyanide of 25%, 1000Kg of water, and 2.5Kg of benzyltrioctylammonium chloride into the catalytic hydrolysis kettle in sequence. Then turn on the stirring speed at 45-50r / min, pass through the separated carbamoyl chloride to decompose the tail gas hydrogen chloride, at this time the tail gas pressure is 0.04 MPa, and the flow rate is 20m 3 / h, the exhaust time is...

Embodiment 2

[0021] Collect the mixed tail gas containing hydrogen chloride, chloroform and methyl isocyanate generated by the decomposition of carbamoyl chloride into the tail gas collection tank, and then condense through the condenser, and the condensed chloroform and methyl isocyanate condensate is transferred to methylamino The formyl chloride mixing tank enters the methyl isocyanate production system for recycling; the hydrogen chloride gas that has not been condensed is used to prepare cartap after being stabilized in the secondary buffer tank.

[0022] Add 346.0Kg of dichloroethane solution with a mass fraction of thiocyanide of 25%, 1000Kg of water, and 2.5Kg of benzyltrioctylammonium chloride into the catalytic hydrolysis kettle in sequence. Then turn on the stirring speed at 45-50r / min, pass through the separated carbamoyl chloride to decompose the tail gas hydrogen chloride, at this time the tail gas pressure is 0.04 MPa, and the flow rate is 20m 3 / h, the exhaust time is...

Embodiment 3

[0024] Collect the mixed tail gas containing hydrogen chloride, chloroform and methyl isocyanate generated by the decomposition of carbamoyl chloride into the tail gas collection tank, and then condense through the condenser, and the condensed chloroform and methyl isocyanate condensate is transferred to methylamino The formyl chloride mixing tank enters the methyl isocyanate production system for recycling; the hydrogen chloride gas that has not been condensed is used to prepare cartap after being stabilized in the secondary buffer tank.

[0025] Add 346.0Kg of dichloroethane solution with a mass fraction of thiocyanide of 25%, 1000Kg of water, and 2.5Kg of benzyltrioctylammonium chloride into the catalytic hydrolysis kettle in sequence. Then turn on the stirring speed at 45-50r / min, pass through the separated carbamoyl chloride to decompose the tail gas hydrogen chloride, at this time the tail gas pressure is 0.03 MPa, and the flow rate is 20m 3 / h, the exhaust gas tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com