Production method and equipment of methyl isocyanate

A technology of methyl isocyanate and production method, applied in the field of methyl isocyanate, can solve the problems of large pollutant discharge, low chemical synthesis reaction yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

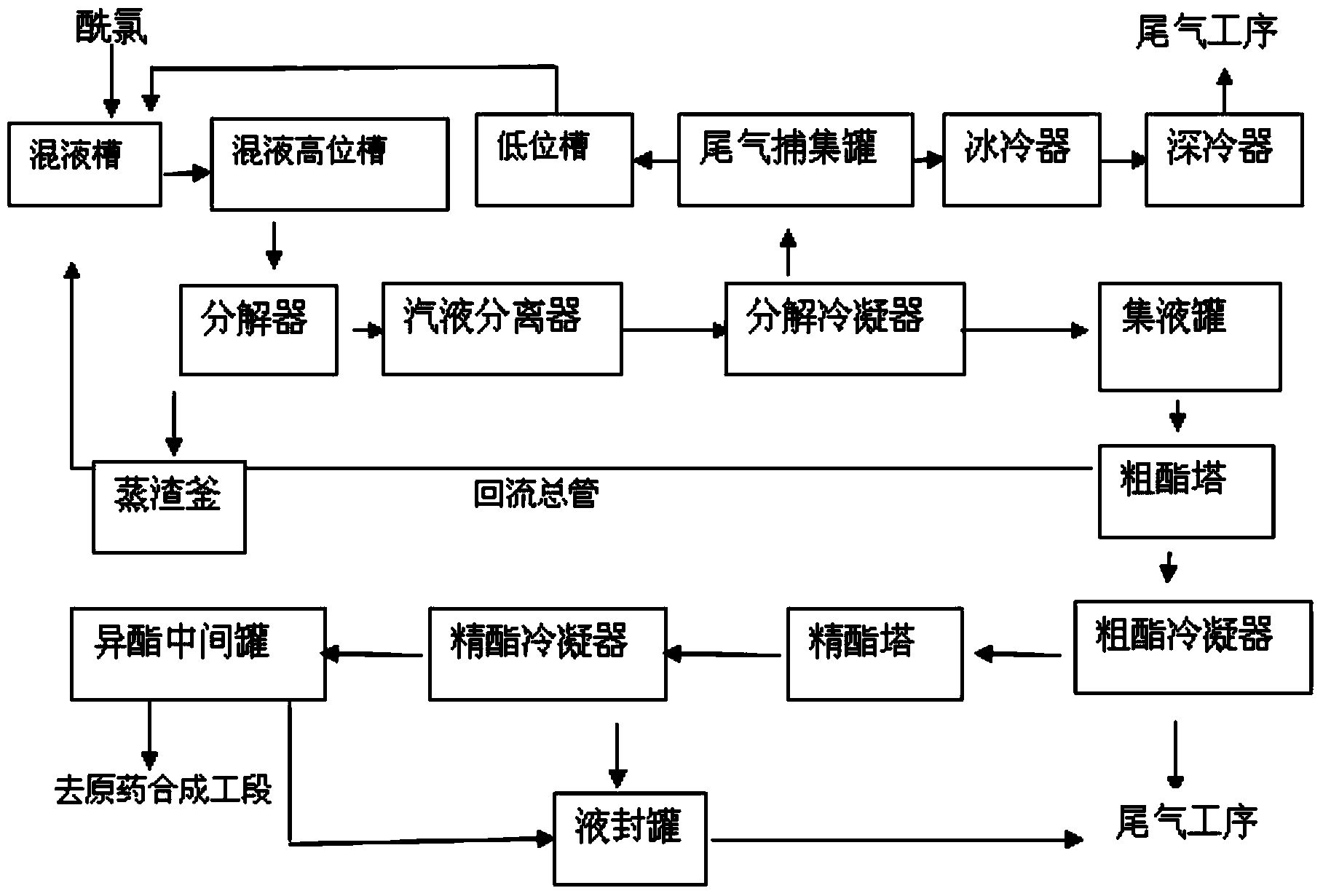

Image

Examples

Embodiment 1

[0023] The production method of methyl isocyanate of the present invention, it comprises the steps:

[0024] (1) with CO 2 , O 2 and coke to produce CO, then CO and chlorine to produce phosgene, and then phosgene and monomethylamine to synthesize methylcarbamoyl chloride; the mass ratio of phosgene and monomethylamine is 3:1; the synthesis reaction of phosgene and monomethylamine The temperature is 250°C.

[0025] (2) After methylcarbamoyl chloride is synthesized, send it to the mixing tank and add solvent for mixing. There is a small amount of methylammonium hydrochloride solid residue in the mixture of acid chloride and solvent, and it is filtered by adding wire mesh filler and 350 mesh filter cloth in two stages The filter is continuously filtered to remove slag and sent to the decomposer; in step (2), the solvent that dissolves methyl isocyanate and enters the slag removal and purification production system is chloroform.

[0026] (3) The mixture of acid chloride and so...

Embodiment 2

[0032] The production method of methyl isocyanate of the present invention, step is the same as embodiment one, difference is: step (1) uses CO 2 , O 2and coke to produce CO, then CO and chlorine to produce phosgene, and then phosgene and monomethylamine to synthesize methylcarbamoyl chloride; the mass ratio of phosgene and monomethylamine is 3.3:1; the synthesis reaction of phosgene and monomethylamine The temperature is 260°C. Step (3) Control the temperature in the decomposer to 140°C; the temperature of the decomposer is controlled from 150 to 180°C to 140°C, which can reduce the production of methyl isocyanate polymers and increase the yield of methyl isocyanate by 93%. A gas-liquid separator is used to guide the high-boiling point substances in the decomposition reaction system to the slag steaming kettle, and the liquid material containing solid slag generated in the material circulation is directed into the slag steaming kettle. When 2000L is collected, the steam is t...

Embodiment 3

[0034] The production method of methyl isocyanate of the present invention, step is the same as embodiment one, difference is: the production method of methyl isocyanate of the present invention, step is the same as embodiment one, difference is: step (1) uses CO 2 , O 2 and coke to produce CO, then CO and chlorine to produce phosgene, and then phosgene and monomethylamine to synthesize methylcarbamoyl chloride; the mass ratio of phosgene and monomethylamine is 3.5:1; the synthesis reaction of phosgene and monomethylamine The temperature was 255°C. Step (3) Control the temperature in the decomposer to 130°C, and control the temperature of the decomposer from 150 to 180°C to 1,30°C, which can reduce the production of methyl isocyanate polymers and increase the yield of methyl isocyanate by 95%. A gas-liquid separator is used to guide the high-boiling point substances in the decomposition reaction system to the slag steaming kettle, and the liquid material containing solid slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com