Hydroxyapatite/polyurethane shape memory bone repair scaffold and preparation method thereof

A technology of hydroxyapatite and polyurethane, applied in medical science, prosthesis, etc., can solve the problems of increased mechanical properties, insufficient mechanical properties, insufficient compressive modulus, shear modulus, and insufficient flexural modulus, etc. Attachment and regeneration, good shape memory performance, and the effect of avoiding bone defect restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The concrete preparation steps of embodiment 1-8:

[0040]Mix the four raw materials of hydroxyapatite, hexamethylene diisocyanate, organic crosslinking agent and polycaprolactone diol and then stir them. The stirring speed is 1000rmp / min, the stirring temperature is 90°C, and the stirring time is 40min. ;Add water to the mixed raw materials and continue to stir. The stirring speed is 1000rmp / min, the stirring temperature is 90°C, and the stirring time is 10-30s. Stop stirring after fine bubbles are found; pour the mixed raw materials into the tetrafluoroethylene mold in the Treat at 80° C. for 24 hours to obtain the hydroxyapatite / polyurethane shape memory bone repair scaffold.

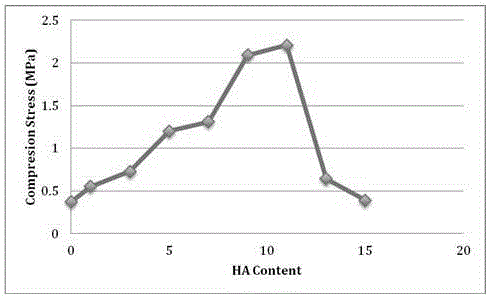

[0041] Comparative example and the compressive strength contrast of embodiment 1-8 please see figure 1 , the mechanical strength of the sample of Example 6 is the best.

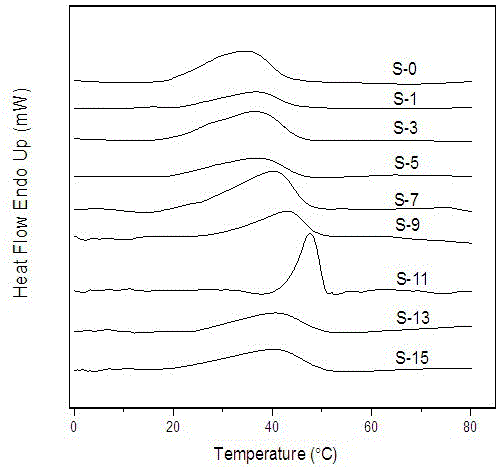

[0042] The response temperature contrast of comparative example and embodiment 1-8 please see figure 2 , because the po...

Embodiment 17

[0048] Example 17 is basically the same as Example 9, except that the loaded drugs are 100 ng / ml of vascular endothelial growth factor, interleukin growth factor and 100 ng / ml of bone morphogenic protein.

[0049] It can be understood that the hydroxyapatite / polyurethane shape memory bone repair scaffold of Examples 1-8 can also be loaded with other active drugs, including various cultured and / or differentiated cells with osteogenic potential.

Embodiment 18

[0050] Example 18: Weigh 100 g of polycaprolactone diol with a molecular weight of 3000 (English abbreviation: PCL3000), 3.81 g of hexamethylene isocyanate (English abbreviation: HDI), and polycaprolactone triol with a molecular weight of 500 7.48 g and 1 g of hydroxyapatite were placed in a three-neck flask, stirred mechanically at 1000 rpm / min, and reacted in an oil bath at 90°C for 40 min; continued at 90°C, added 0.74g of water as a foaming agent, and stirred at 1000 rpm / min, 30s, stop stirring when fine bubbles are found; pour it into a tetrafluoroethylene mold and treat it in an oven at 80°C for 24 hours to obtain a hydroxyapatite / polyurethane shape memory bone repair scaffold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com