Preparation method of novel polymer-based multilayer shape memory material

A polymer material and polymer-based technology, applied in the field of preparation of new polymer-based multilayer shape memory materials, can solve problems such as extended production cycle, low production efficiency, and difficult characterization, and achieve improved shape memory performance and good fixation , the effect of enriching layer interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

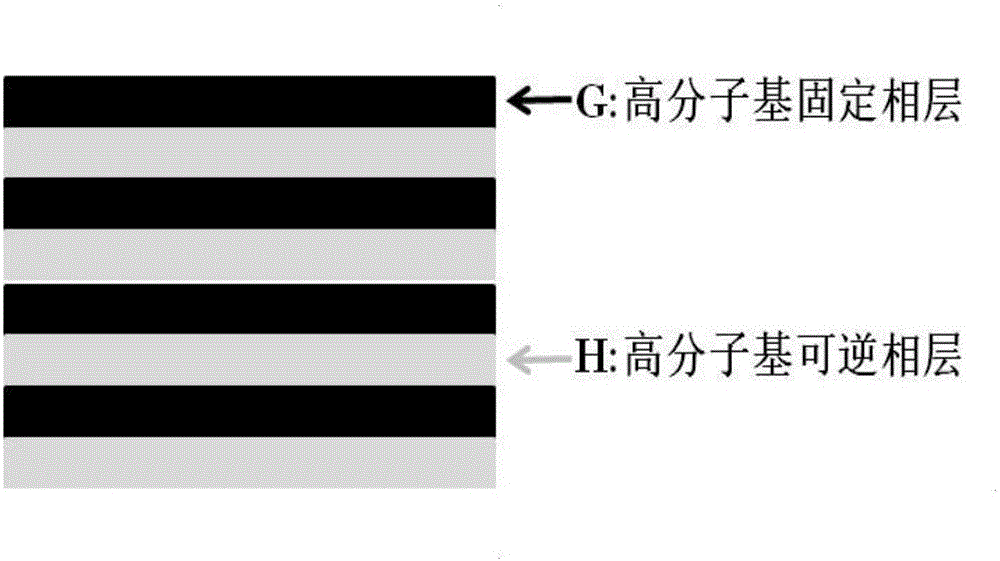

[0041] (1) Styrene-ethylene-butylene-styrene block copolymer (SEBS) (D-1161JP, KRATON ) was selected as the polymer-based stationary phase layer material; polycaprolactone (PCL) (6800, Perstorp Corp) As a polymer-based reversible phase layer material. Before use, the raw materials were placed in a vacuum oven and dried at 80 °C and 40 °C for 24 h to remove moisture.

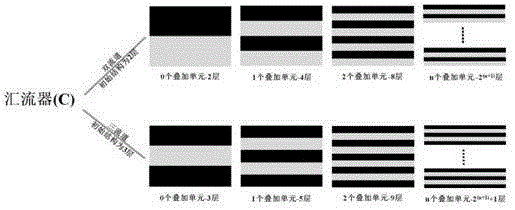

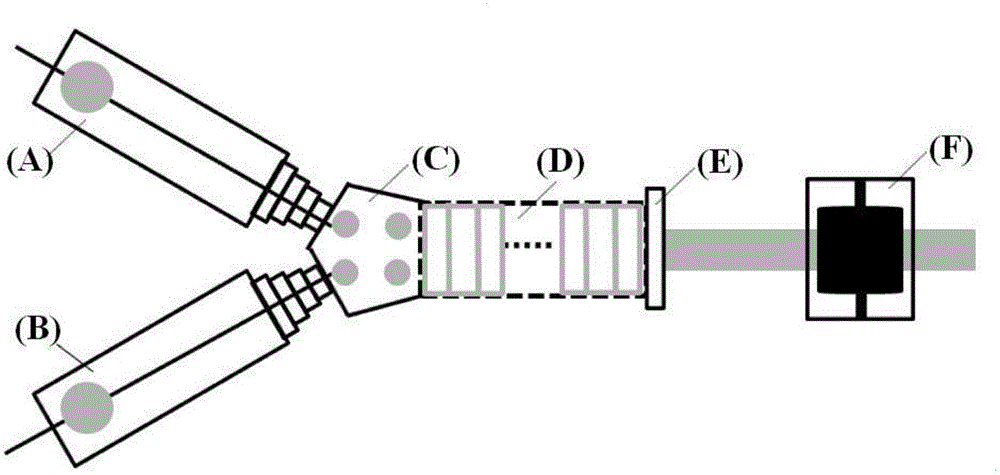

[0042] (2) Put SEBS and PCL into two extruders (A, B) of the multi-layer extrusion system respectively (see figure 1 ), adjust the speed ratio of the extruder to 1:1, and control the temperature of each section of the extruder at 80-175-190-190˚C and 50-175-190-190˚C respectively. After the material in the extruder is melted and plasticized, the two melts are superimposed in the three-channel confluence C to obtain an initial structure with 3 layers, and then cut and layered by 8 layer multipliers D After being superimposed, it flows out from the outlet die E of the rectangular flow channel, in which the temper...

Embodiment 2

[0047] (1) Styrene-polybutadiene-styrene block copolymer (SBS) (YH-791, Balin Petrolem) was selected as the polymer-based stationary phase layer material; polycaprolactone (PCL) (6800, Perstorp Corp ) as a polymer-based reversible phase layer material. Before use, the raw materials were placed in a vacuum oven and dried at 80 °C and 40 °C for 24 h to remove moisture.

[0048] (2) Put SBS and PCL into two extruders (A, B) of the multi-layer extrusion system respectively (see figure 1 ), adjust the speed ratio of the extruder to 7:1, and control the temperature of each section of the extruder at 80-165-180-180°C and 50-165-180-180°C respectively. After the material in the extruder is melted and plasticized, the two melts are superimposed in the three-channel confluence C to obtain an initial structure with 3 layers, and then cut and layered by 12 layer multipliers D After being superimposed, it flows out from the outlet die E of the spiral flow channel, in which the temperatur...

Embodiment 3

[0053] (1) Polyolefin elastomer (POE) (8150, DuPont) was selected as the polymer-based stationary phase layer material; polycaprolactone (PCL) (6800, Perstorp Corp) was selected as the polymer-based reversible phase layer material. Before use, the raw materials were placed in a vacuum oven and dried at 80 °C and 40 °C for 24 h to remove moisture.

[0054] (2) Put POE and PCL into two extruders (A, B) of the multi-layer extrusion system respectively (see figure 1 ), adjust the speed ratio of the extruder to 1:1, and control the temperature of each section of the extruder at 80-175-190-190˚C and 50-175-190-190˚C respectively. After the material in the extruder is melted and plasticized, the two melts are superimposed in the three-channel confluence C to obtain an initial structure with 3 layers, and then cut and layered by 12 layer multipliers D After being superimposed, it flows out from the outlet die E of the rectangular flow channel, in which the temperature of the confluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com