Liquid crystal epoxy resin - carbon fiber composite material and preparation method thereof

An epoxy resin and composite material technology, applied in the field of shape memory polymer material preparation, can solve problems such as high cost and weak mechanical properties, and achieve the effects of excellent performance, improved thermodynamic performance, and strong interface adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

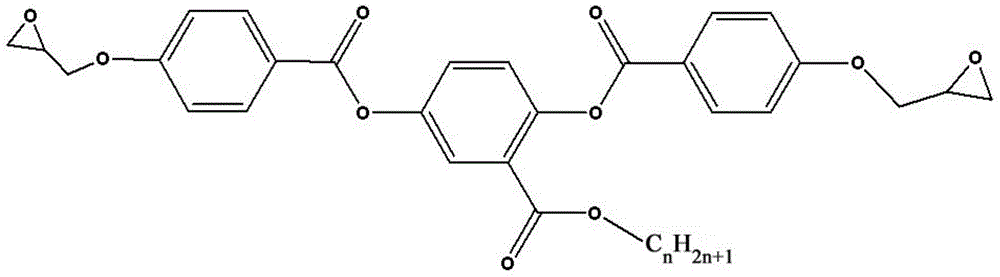

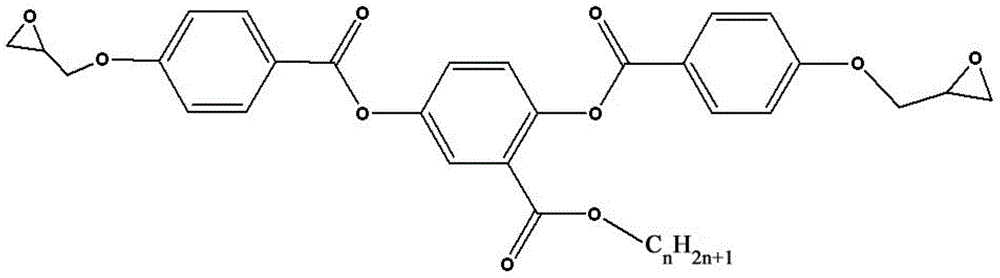

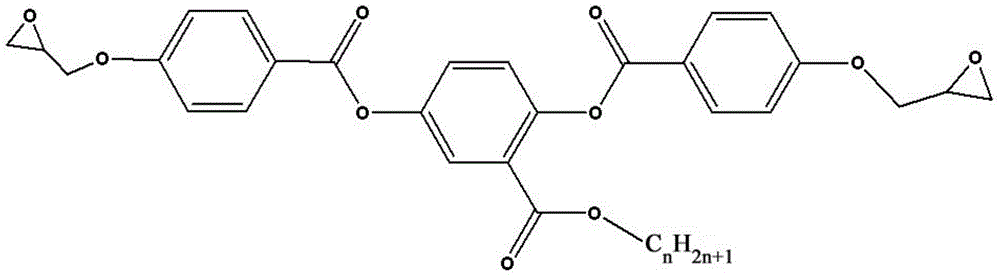

Image

Examples

Embodiment 1

[0032] 1) Soak and clean the chopped carbon fibers with a length of 1 mm in dichloromethane for 100 hours, then take out the chopped carbon fibers and soak them in distilled water for 36 hours, then take out the chopped carbon fibers and dry them in vacuum at 80°C for 36 hours; the dried chopped carbon fibers Place in concentrated nitric acid and stir and reflux at 100°C for 2 hours, then reflux the obtained chopped carbon fibers with distilled water for 24 hours at 100°C, filter, wash the obtained chopped carbon fibers with water, and dry them in vacuum at 100°C for 24 hours; The dried chopped carbon fibers were placed in thionyl chloride, added catalyst dimethylformamide (DMF) and heated to reflux for 3 hours, filtered and washed with tetrahydrofuran to remove excess thionyl chloride, and the solid retentate was acyl chloride Chopped carbon fibers; then put the acid-chlorinated chopped carbon fibers into 4-dimethylaminopyridine (DMAP) containing 0.5% by mass fraction, 20% by ...

Embodiment 2

[0039] 1) Soak and clean the chopped carbon fibers with a length of 6 mm in dichloromethane for 120 hours, then take out the chopped carbon fibers and soak them in distilled water for 40 hours, then take out the chopped carbon fibers and dry them in vacuum at 90°C for 30 hours; the dried chopped carbon fibers Place in concentrated nitric acid, stir and reflux at 105°C for 1.5h, then reflux the obtained chopped carbon fibers with distilled water at 100°C for 24h, filter, wash the obtained chopped carbon fibers with water, and dry them in vacuum at 100°C for 24h; then The chopped carbon fibers after vacuum drying were placed in thionyl chloride, and the catalyst dimethylformamide (DMF) was added and heated to reflux for 3 hours, filtered and washed with tetrahydrofuran to remove excess thionyl chloride, and the solid retained product was acid chloride Chopped carbon fiber; then put the acid chlorinated chopped carbon fiber into 4-dimethylaminopyridine (DMAP) containing 0.8% by ma...

Embodiment 3

[0046] 1) Soak and clean the chopped carbon fibers with a length of 12 mm in dichloromethane for 140 hours, then take out the chopped carbon fibers and soak them in distilled water for 48 hours, then take out the chopped carbon fibers and dry them in vacuum at 100°C for 24 hours; the dried chopped carbon fibers Place in concentrated nitric acid, stir and reflux at 110°C for 1 hour, then reflux the obtained chopped carbon fibers with distilled water at 100°C for 24 hours, filter, wash the obtained chopped carbon fibers with water, and dry them under vacuum at 100°C for 24 hours; The dried chopped carbon fibers were placed in thionyl chloride, added catalyst dimethylformamide (DMF) and heated to reflux for 3 hours, filtered and washed with tetrahydrofuran to remove excess thionyl chloride, and the solid retentate was acyl chloride Chopped carbon fibers; then put the acid-chlorinated chopped carbon fibers into 4-dimethylaminopyridine (DMAP) containing 1% by mass fraction, 30% by m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com