Cross-linking type shape memory polyurethane

A cross-linked, polyurethane technology, applied in the field of polymer material preparation, can solve the problem of low cross-linking density of memory polyurethane, and achieve the effects of good shape fixation rate, fast recovery response speed and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1). In N 2 Under protection, add MDI to a three-necked flask equipped with a stirrer, put the three-necked flask into an oil bath and heat to 80°C, and then add dehydrated 1,4-dioxane with a mass fraction of 25 % PCL solution, mechanically stirred and reacted for 3 hours to prepare an MDI-terminated polyurethane prepolymer; cool the obtained MDI-terminated polyurethane prepolymer to 25°C, add γ-aminopropyltriethoxysilane to carry out React for 1 hour to obtain a polyurethane prepolymer terminated with silicon ethoxy groups; wherein: the molar ratio of PCL: MDI: γ-aminopropyltriethoxysilane is 1: 1.8: 1;

[0039] (2). Place the silicon ethoxy-terminated polyurethane prepolymer obtained in step (1) directly at room temperature for chain extension and cross-linking reaction for 12 hours, and dry to obtain a film of cross-linked polyurethane; place it at room temperature for one week to obtain a dense structure cross-linked shape memory polyurethane. Tensile test of this...

Embodiment 2

[0041] (1). With step (1) in embodiment 1;

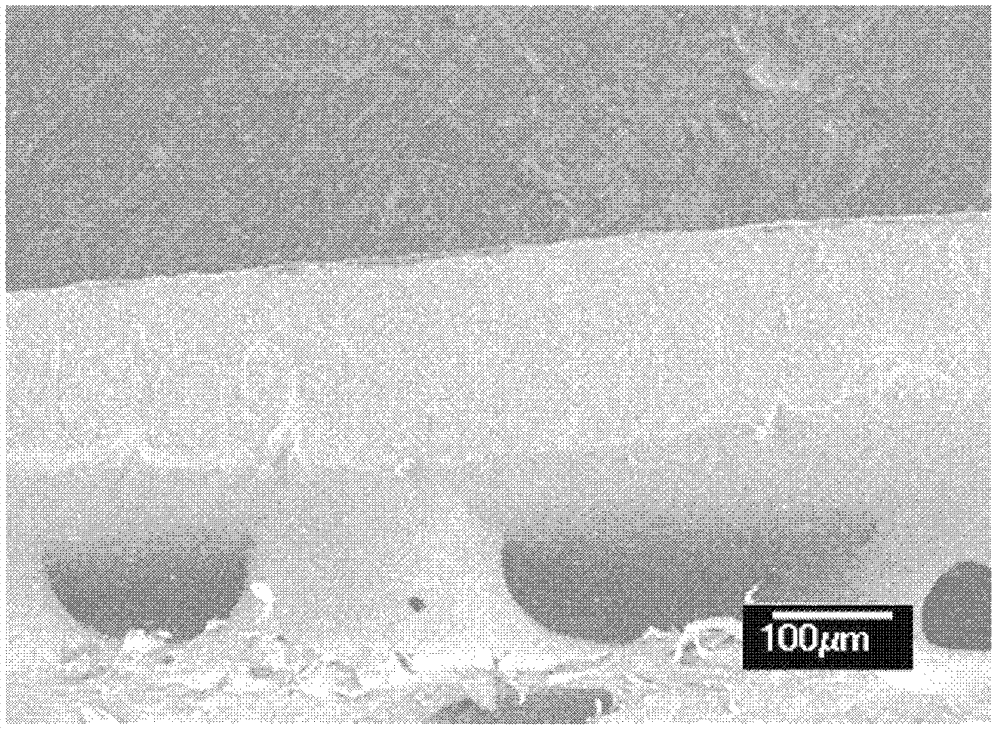

[0042] (2). Add aqueous HCl solution to the polyurethane prepolymer obtained in step (1), where: γ-aminopropyltriethoxysilane: HCl: H 2 The molar ratio of O is 1:0.05:3. After stirring evenly, carry out the hydrolysis chain extension crosslinking reaction at room temperature for 12 hours, and dry to obtain a crosslinked polyurethane film; Film of cross-linked shape memory polyurethane. Tensile test of this cross-linked shape memory polyurethane, the shape fixation rate (R f ) is 100%, the shape recovery rate (R r ) is 100%. The SEM photo of its cross-section is shown in figure 1 .

Embodiment 3

[0044] (1). With step (1) in embodiment 1;

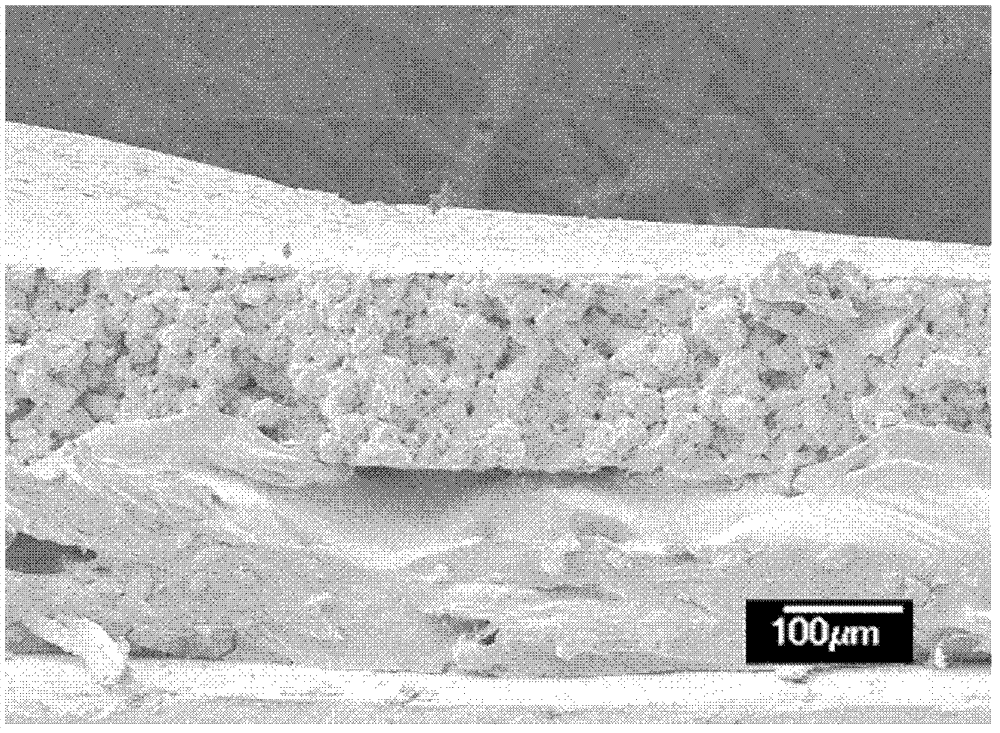

[0045] (2). Add aqueous HCl solution to the polyurethane prepolymer obtained in step (1), where: γ-aminopropyltriethoxysilane: HCl: H 2 The molar ratio of O is 1:0.05:35. After stirring evenly, carry out the hydrolytic chain extension cross-linking reaction at room temperature for 36 hours, and dry to obtain a cross-linked polyurethane film; A cross-linked shape memory polyurethane with a porous structure of micropores. Tensile test of this cross-linked shape memory polyurethane, the shape fixation rate (R f ) is 100%, the shape recovery rate (R r ) is 100%. The SEM photo of its cross-section is shown in figure 2 .

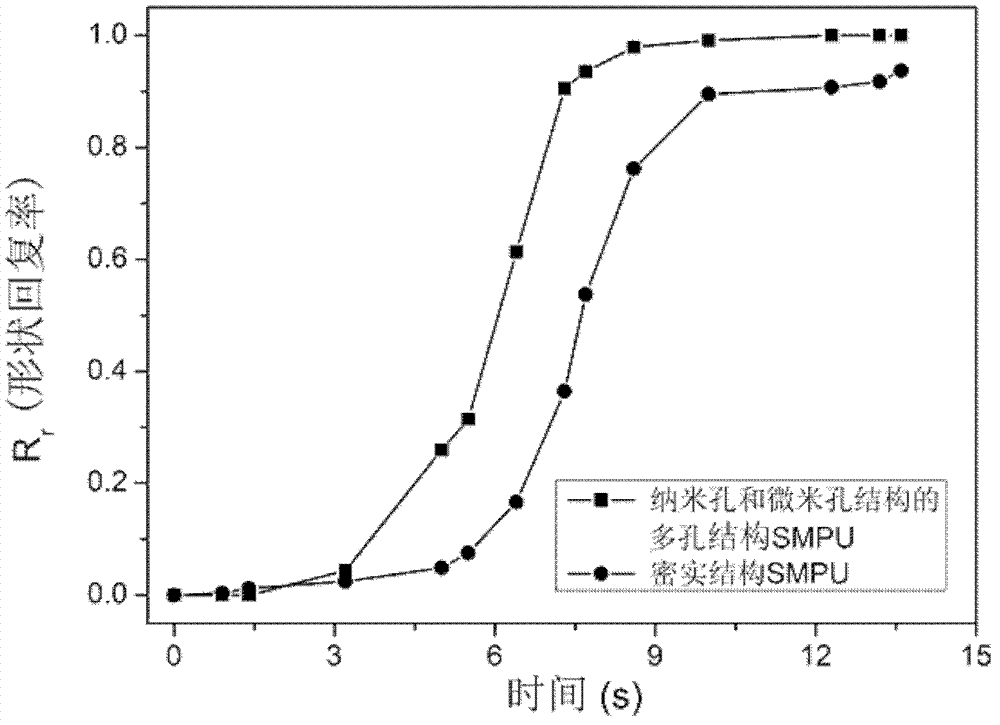

[0046] The cross-linked shape-memory polyurethane material with a porous structure of nanopores and micropores prepared in Example 3 and the dense structure shape-memory polyurethane material prepared in Example 2 of the same size were bent to the same shape at 50°C. appearance, and record the recovery process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com