PVA hydrogel, composite material using same and preparation method and application of PVA hydrogel

A composite material and hydrogel technology, applied in pharmaceutical formulations, catheters, medical science and other directions, can solve the problems of poor mechanical properties and complex preparation process, and achieve the effect of simple manufacturing process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

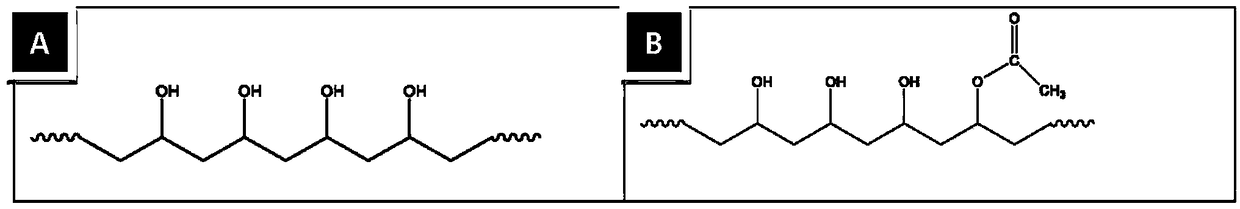

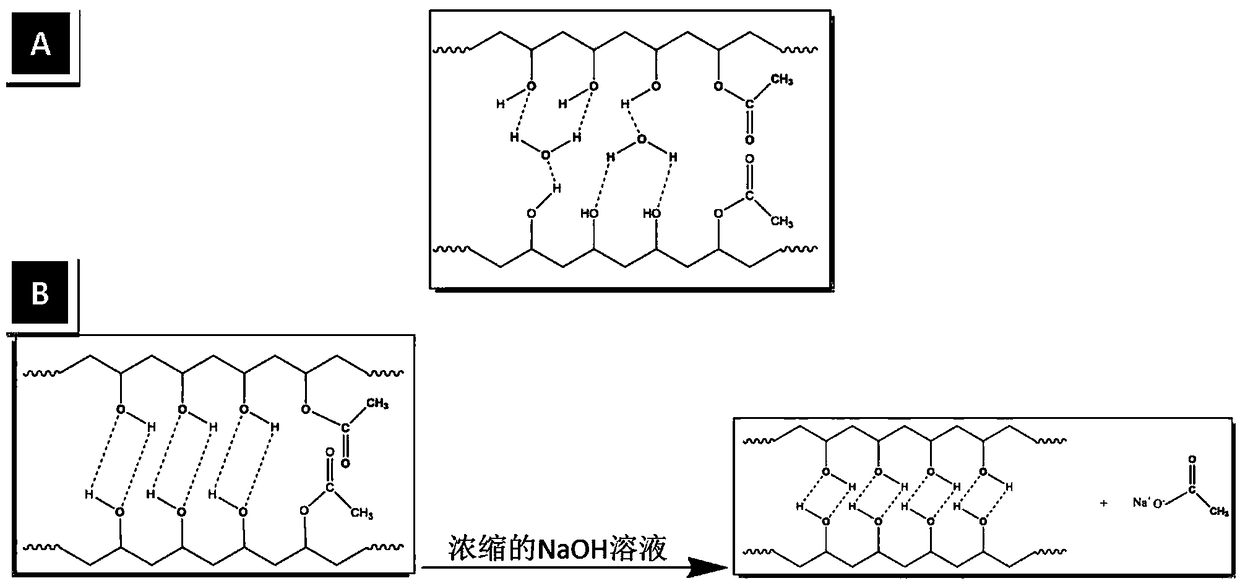

Method used

Image

Examples

Embodiment 1

[0060] A viscous solution of PVA was formed by dissolving PVA with a molecular weight of 205,000 in distilled water to make 10% PVA (100 mg / mL; 10 g of PVA in 100 ml of distilled water) and placing in a shaking bath heated at 60°C overnight. Then pour 20ml of 10% PVA solution into a glass dish with a diameter of 10cm, dry it overnight at room temperature, then immerse it in a NaOH solution with a molar concentration of 1M for 10-20 minutes, wash it with pure water after gelation, and wash it Drain and store in airtight.

Embodiment 2

[0062] The PVA hydrogel was prepared using the same method as in Example 1, except that the concentration of NaOH was changed to 3M.

Embodiment 3

[0064] The PVA hydrogel was prepared using the same method as in Example 1, except that the concentration of NaOH was changed to 5M.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com