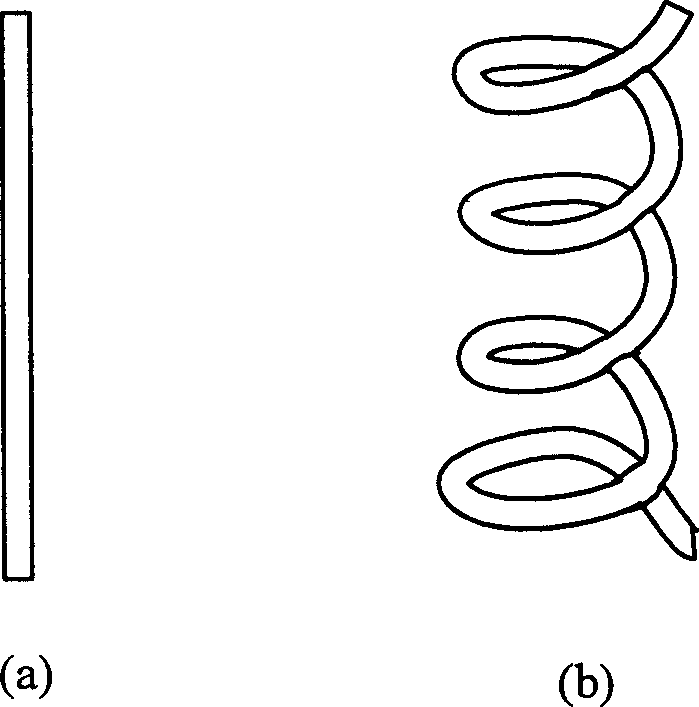

Preparation method of degradable polymer material for stent in shape memory pipe cavity

A technology of polymer materials and memory tubes, applied in medical science, prostheses, etc., to achieve good biocompatibility and good shape memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

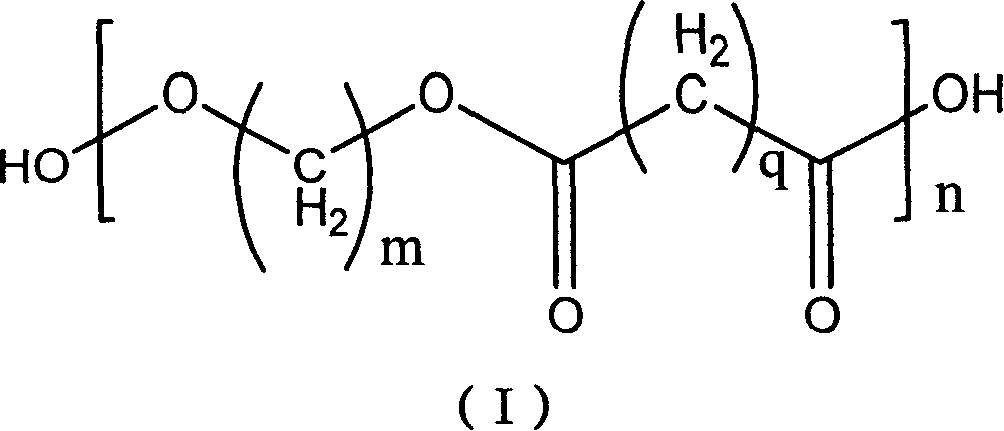

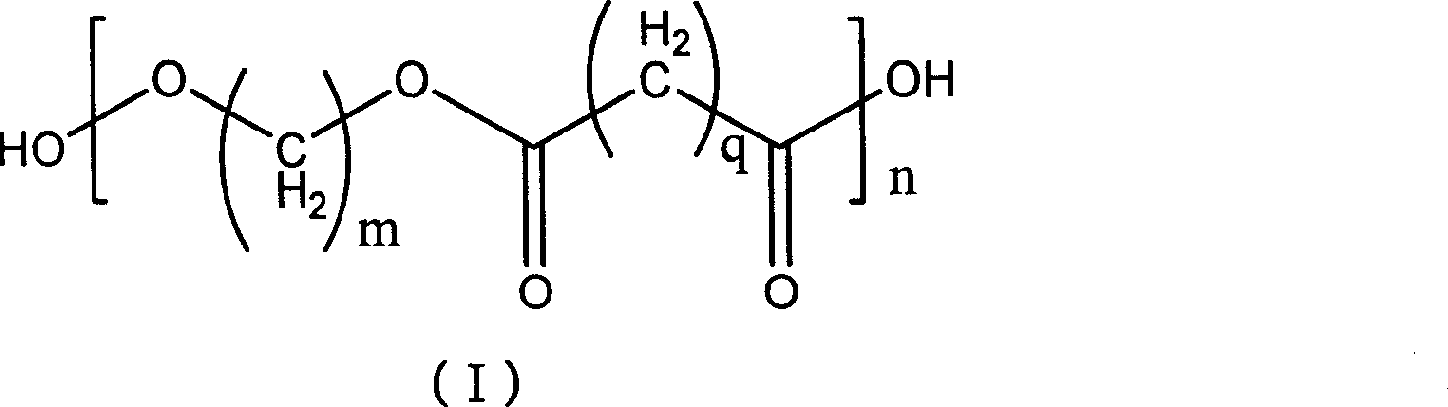

Method used

Image

Examples

Embodiment 1

[0028] L-lactide (LLA), glycolide (GL) refined by ethanol recrystallization method, ethylene glycol, stannous octoate as raw materials, L-lactide (LLA), glycolide (GL) Molar ratio is 1: 6, and the ratio of ethylene glycol and L-lactide (LLA) and glycolide (GL) molar weight sum is 1: 20, add catalyst stannous octoate (0.05wt%, with LLA and GL total mass) at 140°C and N 2 Under protection, the pressure was reduced to 50 Pa, and the melt polymerization was carried out for 12 hours. After the reaction, add tetrahydrofuran to dissolve, then add methanol to precipitate and purify the product, and dry it in vacuum to obtain a white powdery hydroxyl-terminated PLGA for future use; Polyester polybutylene succinate (PBS), hexamethylene diisocyanate (HDI) as raw materials, the molar ratio of PLGA and polybutylene succinate (PBS) is 1:3, hexamethylene The molar ratio of HDI to PLGA and PBS is 1:2, at 150°C and N 2 Under protection, the pressure was reduced to 50 Pa, and the melting rea...

Embodiment 2

[0031] D, L-lactide (DLLA), glycolide (GL), 1,3-propanediol and stannous chloride refined by ethanol recrystallization method are used as raw materials, D, L-lactide (DLLA), The molar ratio of glycolide (GL) is 1:1, the ratio of ethylene glycol to D, L-lactide (DLLA) and glycolide (GL) molar weight sum is 1:25, add catalyst chlorinated Tin (0.1wt%, based on the total mass of DLLA and GL) at 160 ° C and N 2 Under protection, the pressure was reduced to 65 Pa, and the melt polymerization was carried out for 18 hours. After the reaction, add tetrahydrofuran to dissolve, then add methanol to precipitate and purify the product, and dry it in vacuum to obtain a white powdery hydroxyl-terminated PLGA for future use; Polyester polybutylene adipate (PBA), hexamethylene diisocyanate (HDI) as raw material, the molar ratio of PLGA, polybutylene adipate (PBA) is 1:1, hexamethylene The molar ratio of HDI to PLGA and PBA is 1:1, at 160°C and N 2 Under protection, the pressure was reduced ...

Embodiment 3

[0034] D, L-lactide (DLLA), glycolide (GL), 1,4-butanediol, stannous octoate refined by ethanol recrystallization method as raw materials, D, L-lactide (DLLA) , The molar ratio of glycolide (GL) is 6: 1, the ratio of ethylene glycol and D, L-lactide (DLLA) and glycolide (GL) molar weight sum is 1: 30, add catalyst octanoic acid sulfide Tin (0.1wt%, based on the total mass of DLLA and GL) at 180 ° C and N 2 Under protection, the pressure was reduced to 70 Pa, and the melt polymerization was carried out for 20 hours. After the reaction, add tetrahydrofuran to dissolve, then add methanol to precipitate and purify the product, and dry it in vacuum to obtain a white powdery hydroxyl-terminated PLGA for future use; Polyester adipate (PHA), lysine diisocyanate (LDI) as raw material, PLGA, polyhexamethylene adipate (PHA) molar ratio is 3:1, lysine diisocyanate (LDI) The molar ratio of isocyanate (LDI) to PLGA and PHA is 2:1, at 180°C and N 2 Under protection, the pressure was reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com