A polylactic acid-based super-tough blending material with shape memory effects or a polylactic acid-based super-tough high-strength blending nanometer composite material with shape memory effects, and preparing methods thereof

A memory effect, polylactic acid-based technology, applied in the field of polymer materials and their preparation, can solve the problems such as shape memory effect and reduced toughness of composite materials that are not mentioned, and achieve easy promotion, high toughness and strength, and good shape memory performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] PLA and GPOE were mechanically mixed at a mass ratio of 80:20, and then the premixed material was put into a multi-sided channel convective screw extruder for melt blending to obtain a PLA-based blended material. The screw speed of the extruder is 20r / min, and the barrel temperature is 170-190°C.

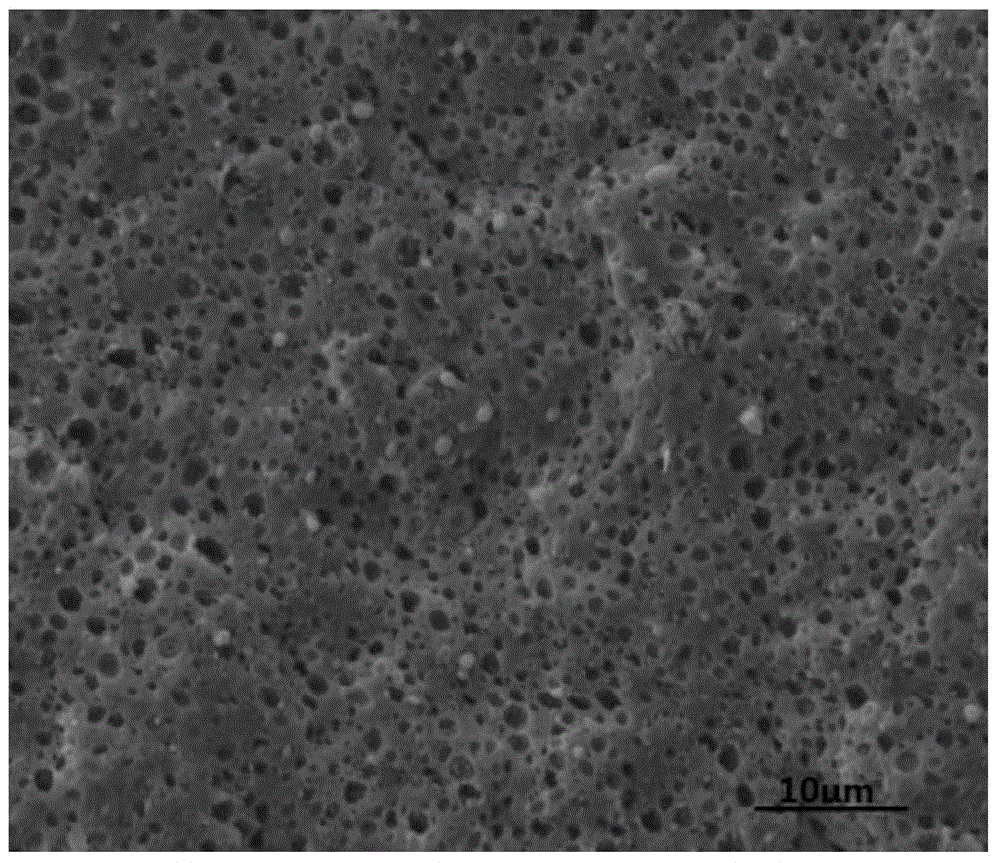

[0030] Figure la is the SEM photo of the prepared 80:20 PLA / GPOE blend material, in which the GPOE phase is etched. It can be seen that the phase morphology of GPOE is micron-sized droplets with an average diameter of about 1.2 μm. The tensile curve of the prepared 80:20PLA / GPOE blend material is shown in Figure 3a The "PLA80" curve shows that the tensile strength of the blended material is 33.6MPa, and the elongation at break is 171.6%, while the elongation at break of PLA is only 2.1% (see Figure 3a "PLA100" curve); by Figure 3b It can be seen that the Izod notched impact strength of the blended material at -20°C is 21.7kJ / m 2 , is PLA (0.82kJ / m 2 ) 26 times, that i...

Embodiment 2

[0032]PLA and GPOE were mechanically mixed at a mass ratio of 90:10, and then the premixed material was put into a multi-sided channel convective screw extruder for melt blending to obtain a PLA-based blended material. The screw speed of the extruder is 20r / min, and the barrel temperature is 170-190°C.

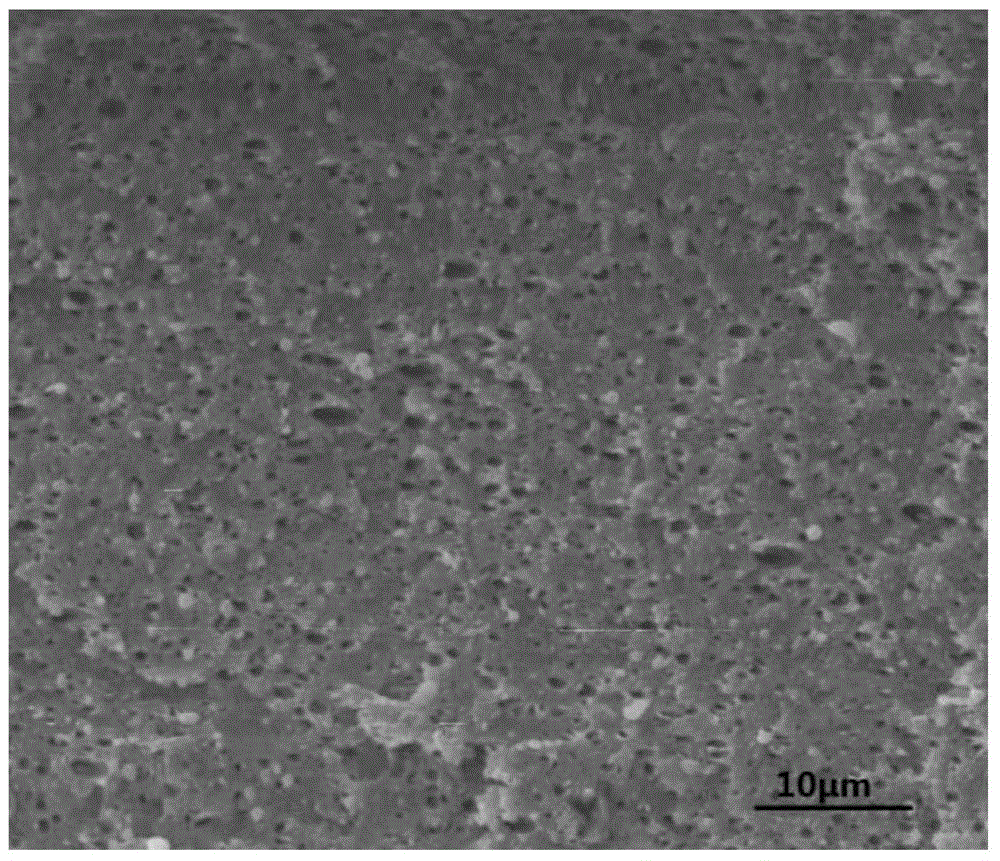

[0033] Figure 1b It is the SEM photo of the prepared 90:10 PLA / GPOE blend material, in which the GPOE phase is etched. It can be seen that the phase morphology of GPOE is micron-sized droplets with an average diameter of about 0.67 μm. The tensile curve of the prepared 90:10PLA / GPOE blend material is shown in Figure 3a The "PLA90" curve shows that the tensile strength of the blended material is 42.2MPa, and the elongation at break is 107.7%; Figure 3b It can be seen that the Izod notched impact strength of the blended material at -20°C is 16.8kJ / m 2 , is PLA (0.82kJ / m 2 ) 20 times, that is, the addition of 10% GPOE and the micron-scale droplet phase morphology greatly ...

Embodiment 3

[0035] PLA and GPOE were mechanically mixed at a mass ratio of 70:30, and then the premixed material was put into a multi-sided channel convective screw extruder for melt blending to obtain a PLA-based blended material. The screw speed of the extruder is 50r / min, and the barrel temperature is 170-190°C.

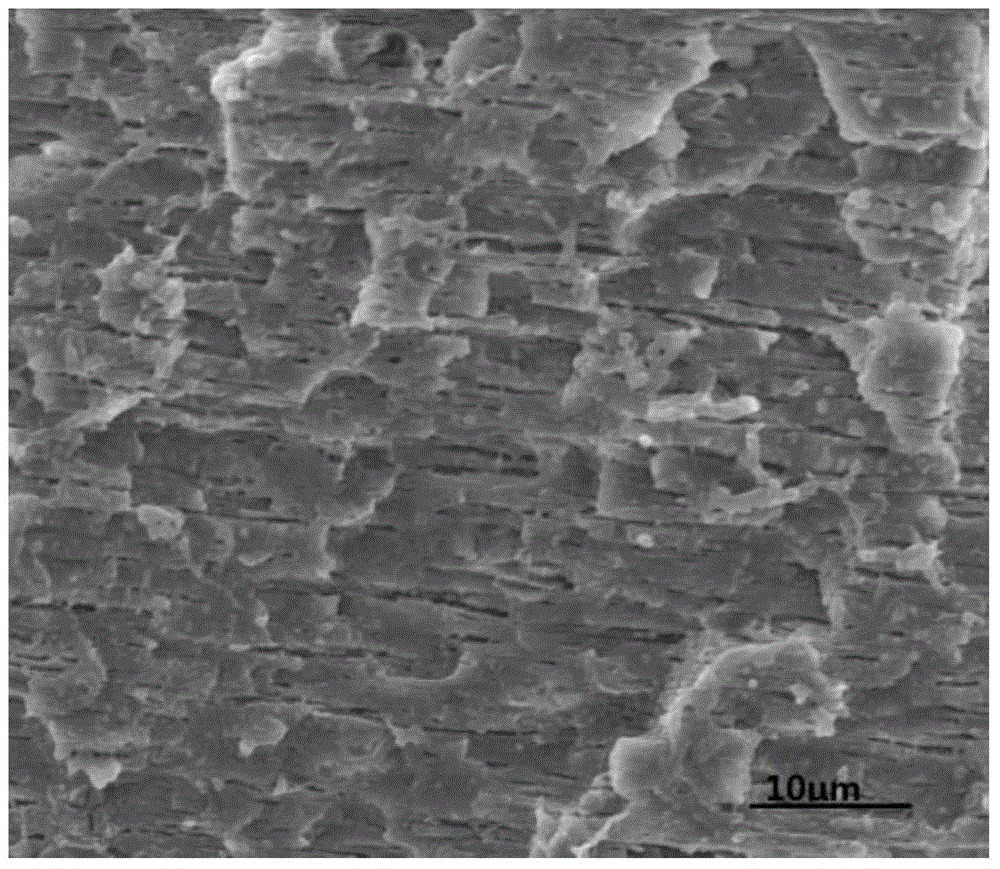

[0036] Figure lc is the SEM photo of the prepared 70:30 PLA / GPOE blend material, in which the GPOE phase is etched. It can be seen that the phase morphology of GPOE is fiber, and its average aspect ratio is about 19.5. The tensile curve of the prepared 70:30PLA / GPOE blend material is shown in Figure 3a The "PLA70" curve shows that the tensile strength of the blended material is 27.1 MPa, and the elongation at break is 211.1%; Figure 3b It can be seen that the Izod notched impact strength of the blended material at -20°C is 31.7kJ / m 2 , is PLA (0.82kJ / m 2 ) 39 times, that is, the addition of 30% GPOE and the appearance of fiber phase form greatly improved the toughness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com