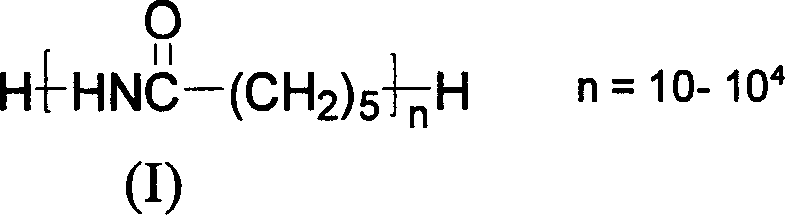

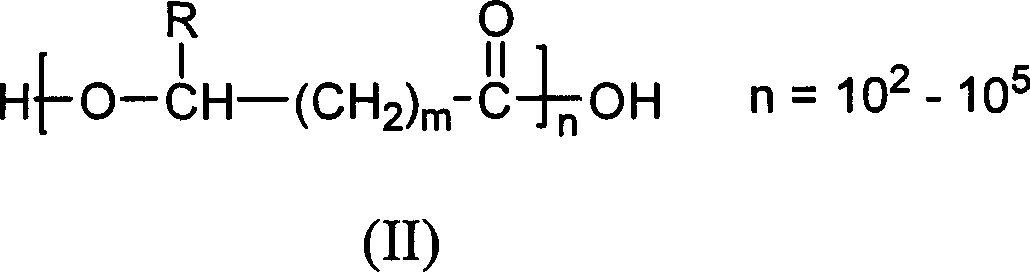

Novel block macromolecular material and preparation method thereof

A technology of block polymers and polymers, applied in the field of block polymer materials and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

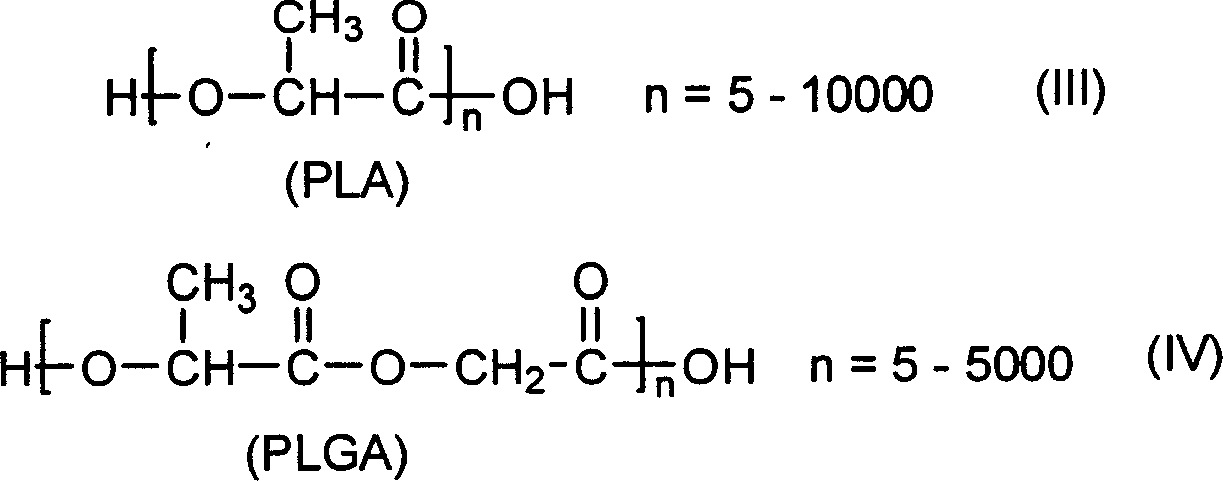

[0052] Preparation of low molecular weight PHB fragments

[0053] Weigh 2.5g of PHB polymer (Jiangsu Nantian Group) with a molecular weight of 500,000 in a 100ml round bottom flask, add 50mL of CHCl 3 , condensed and refluxed in an oil bath at 65°C for about 120min, let the PHB dissolve slowly, and added 1mL of concentrated H 2 SO 4 Put it into the above solution, raise the temperature and reflux for 30min, transfer the above solution to a separatory funnel after cooling, add about 15mL of distilled water to wash, add anhydrous MgSO 4 Water was removed and the filtered solution was distilled to remove CHCl 3 , to obtain PHB solids, add water to wash the PHB solids, and filter to obtain 1.3 g of PHB fragments with a molecular weight of 2000 for the preparation of block copolymers. NMR (500MHz, CDCl 3 ): δppm 1.3 (CH 3 ), 2.5-2.6 (CO-CH 2 ), 5.2-5.3 (COO-CH).

Embodiment 2

[0055] Preparation of low molecular weight PHB diol fragments

[0056] Weigh 2.5g of PHB (Jiangsu Nantian Group) polymer with a molecular weight of 500,000 in a 100mL round bottom flask, add 50mL of CHCl 3 and 5.0 mL of ethylene glycol. Condensate and reflux in an oil bath at 65°C for about 120 minutes to allow PHB to slowly dissolve. 1 mL of concentrated H was added dropwise 2 SO 4 Into the above solution, heat up and reflux for 30 minutes, and transfer the above solution to a separatory funnel after cooling. Add about 15mL of distilled water to wash, add anhydrous MgSO 4 In addition to water, the filtered solution was distilled to remove CHCl 3 , to obtain PHB solid. Water was added to wash the PHB solid, and filtered to obtain 1.3 g of PHB diol fragments with a molecular weight of 2000 for use in the preparation of block copolymers. NMR (500MHz, CDCl 3 ): δppm 1.3 (CH 3 ), 2.5-2.6 (CO-CH 2 ), 5.2-5.3 (COO-CH).

Embodiment 3

[0058] Preparation of low molecular weight PHBHHx diol fragments

[0059] Weigh 2.50g of PHBHHx polymer (Guangdong Lianyi Bioengineering Co., Ltd.) with a molecular weight of 750,000 in a 100mL round bottom flask, add 50mL of CHCl 3 and 5.0 mL of ethylene glycol. Condensate and reflux in an oil bath at 65°C for about 30 minutes, let PHBHHx dissolve slowly, add 1 mL of concentrated H 2 SO 4 into the above solution. Raise the temperature and reflux for 10 min, and transfer the above solution to a separatory funnel after cooling. Add about 15mL of distilled water to wash, add anhydrous MgSO 4 In addition to water, the filtered solution was distilled to remove CHCl 3 , to obtain PHB solid. Add water to wash the PHB solid, and filter to obtain 2.1 g of PHBHHx diol fragments with a molecular weight of 5000 for the preparation of block copolymers. NMR (500MHz, CDCl 3 ): δppm 0.9 (CH 3 ), 1.3 (CH 2 ), 2.5-2.6 (CO-CH 2 ), 5.2-5.3 (COO-CH).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com