Polyurethane/epoxy resin blend with shape memory, self-repairing and recyclability functions and preparation method thereof

An epoxy resin and polyurethane technology, which is applied in the field of polyurethane/epoxy resin blends and their preparation, can solve the problems of inability to take into account self-healing, low strength of TPU materials, etc., and achieve self-healing and recycling performance improvement and mechanical performance enhancement. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 14.466g of polycarbonate diol with a molecular weight of 1000 and heat and melt it, and dissolve 7.235g of isophorone diisocyanate and 0.042g of dibutyltin dilaurate in 20g of N,N-dimethylformamide and added dropwise to polycarbonate diol, stirred and reacted at 70°C for 3 hours to obtain a polyurethane prepolymer;

[0028] (2) Dissolve 0.449g of 4,4'-diaminodiphenyl disulfide and 0.021g of dibutyltin dilaurate in 20g of N,N-dimethylformamide, and add them dropwise to step (1) In the obtained polyurethane prepolymer, stirring and reacting at a temperature of 70° C. for 4 hours to obtain a TPU material whose main chain contains a disulfide bond;

[0029] (3) Dissolve 24g of epoxy resin and 6.848g of furfurylamine in 40g of N,N-dimethylformamide, stir and react at 100°C for 6h to obtain an epoxy resin prepolymer;

[0030] (4) Dissolve the TPU (7g) obtained in step (2) and the epoxy resin prepolymer (2.129g) obtained in step (3) in 40g N,N-dimethylformamide and ...

Embodiment 2

[0033] (1) Weigh 14.466g of polycarbonate diol with a molecular weight of 1000 and heat and melt it, and dissolve 7.235g of isophorone diisocyanate and 0.042g of dibutyltin dilaurate in 20g of N,N-dimethylformamide and added dropwise to polycarbonate diol, stirred and reacted at 70°C for 3 hours to obtain a polyurethane prepolymer;

[0034] (2) Dissolve 0.449g of 4,4'-diaminodiphenyl disulfide and 0.021g of dibutyltin dilaurate in 20g of N,N-dimethylformamide, and add them dropwise to step (1) In the obtained polyurethane prepolymer, stirring and reacting at a temperature of 70° C. for 4 hours to obtain a TPU material whose main chain contains a disulfide bond;

[0035] (3) Dissolve 24g of epoxy resin and 6.848g of furfurylamine in 40g of N,N-dimethylformamide, stir and react at 100°C for 6h to obtain an epoxy resin prepolymer;

[0036] (4) Dissolve the TPU (7g) obtained in step (2) and the epoxy resin prepolymer (2.129g) obtained in step (3) in 40g N,N-dimethylformamide and ...

Embodiment 3

[0039] The method for preparing polyurethane / epoxy resin blend with reference to embodiment 2, difference is that step (4): with step (2) gained TPU (7g) and step (3) gained epoxy resin prepolymer (2.129g) dissolve In 40g N,N-dimethylformamide, stir evenly at 70°C, and add 0.871g 4,4'-methylenebis(N-phenylmaleimide) at room temperature, stir After uniformity, it is poured into a mold and dried at a temperature of 70° C. to obtain a multifunctional polyurethane / epoxy resin blend.

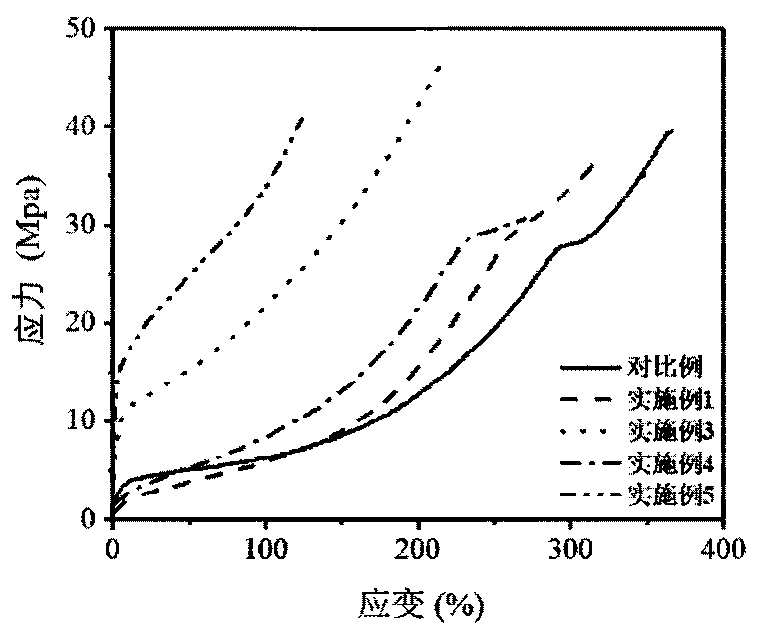

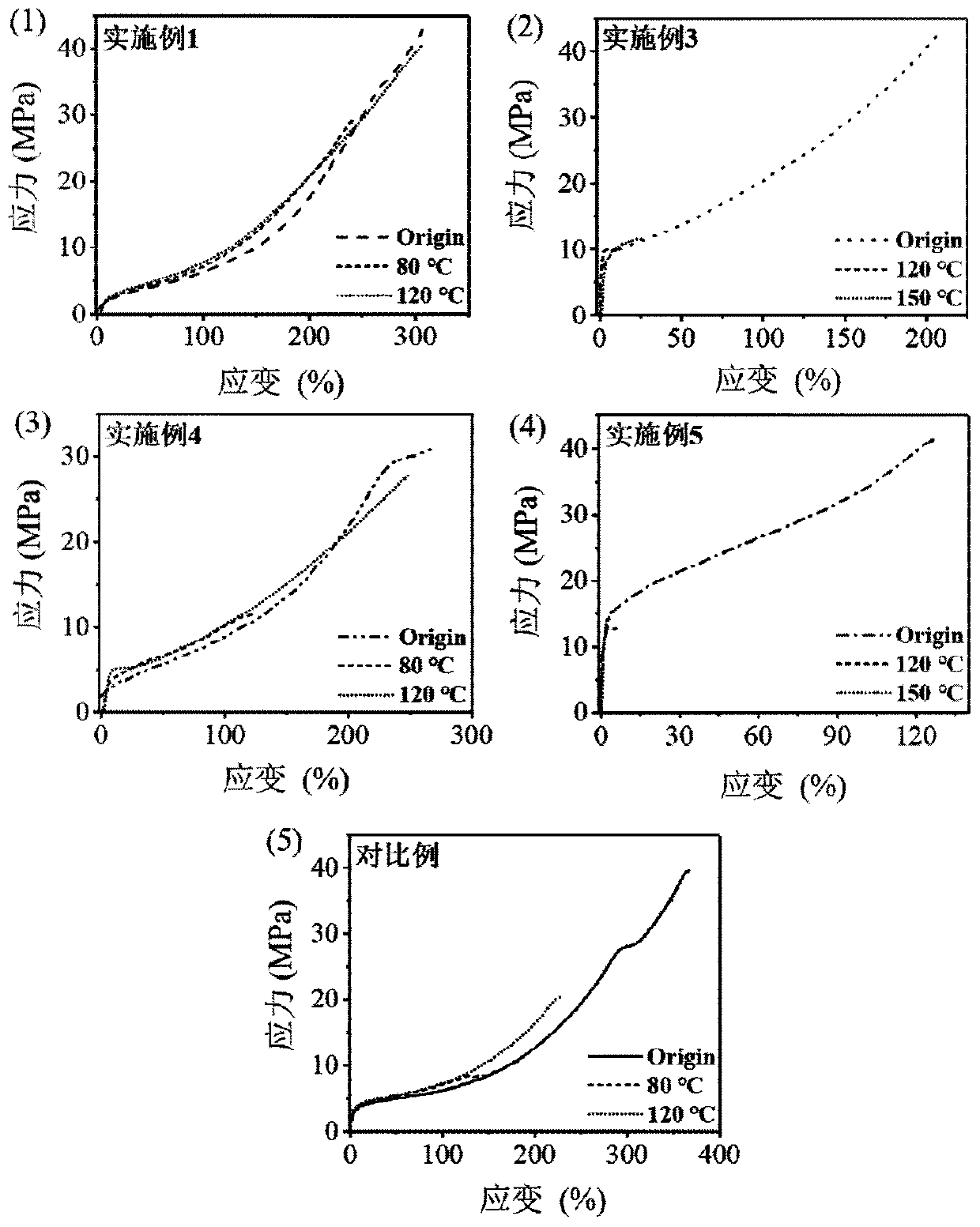

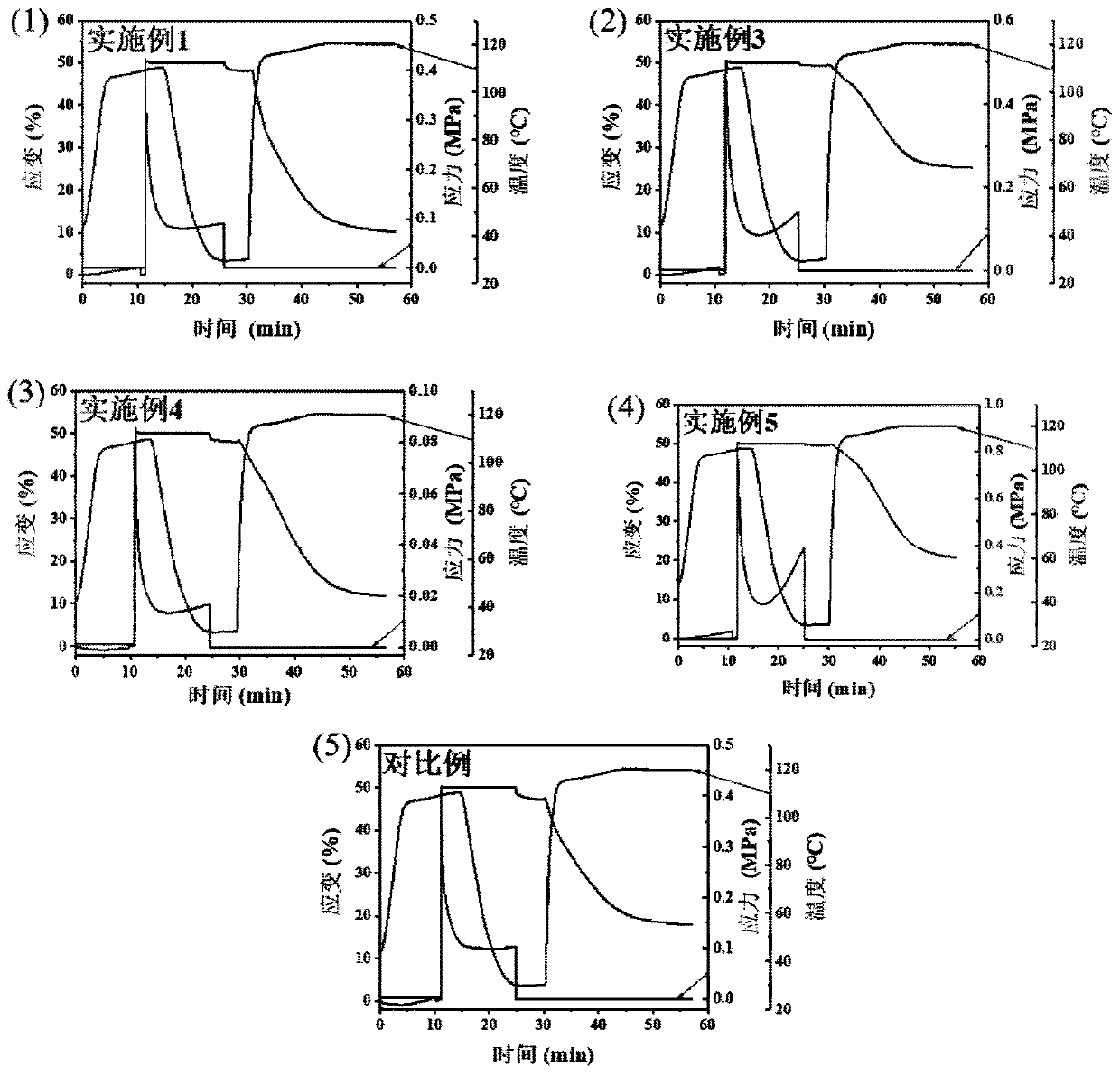

[0040] The self-repair, shape memory performance test and mechanical performance test before and after recovery of the blend are carried out as follows: the prepared blend sample is cut in the middle with a sharp blade, and the samples are respectively tested at 120 ° C and 150 ° C After heating and repairing for 6 hours, the sample was heat-treated at 60°C for 72 hours before tensile testing, and the repairing effects of the tensile test reached 23.59% and 27.32% respectively; the sample was heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com