Brocade cotton fabric short-process dyeing method

A dyeing method and technology of nylon-cotton fabrics, applied in the field of printing and dyeing in the textile manufacturing industry, can solve the problems of high energy consumption, unstable product quality, and high requirements for dyeing and chemical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

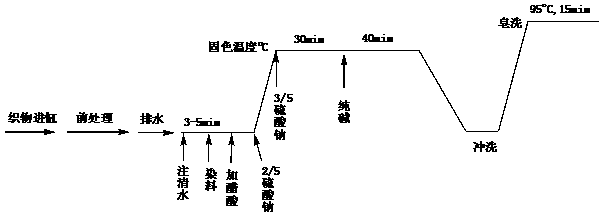

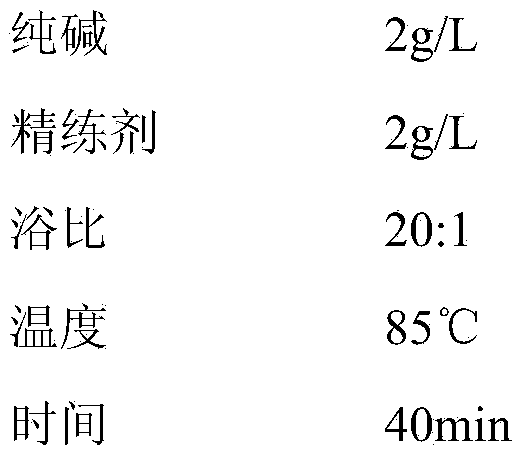

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: middle temperature type reactive dye dyeing

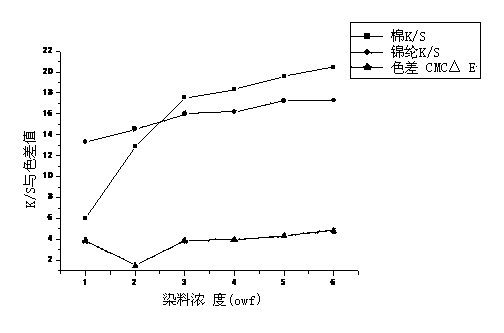

[0064] 1.1 Orthogonal test

[0065] In order to systematically study the effects of various factors on the coloring of nylon and cotton fabrics during the one-bath dyeing of reactive dyes, the orthogonal design method was used to study the mixed samples of nylon and cotton according to the dyeing temperature from low to high. The results are shown in Table 3- 5. The medium-temperature reactive dyes used in the following experiments are reactive BES red (supplied by Shangyu Yide Chemical Co., Ltd.).

[0066] Table 3 Orthogonal Design Test (1)

[0067]

[0068] Table 4 Orthogonal Design Test (2)

[0069]

[0070] Table 5 Orthogonal Design Test (3)

[0071]

[0072]

[0073] (1) Electrolyte influence

[0074] From the data in Table 3-5 above, it is found that the electrolyte has a significant effect on the dyeing of cotton fabrics. As the electrolyte concentration increases, the K / S value of cotto...

Embodiment 2

[0134] Embodiment 2: high temperature type reactive dye dyeing

[0135] 2.1 Orthogonal design experiment

[0136] Table 12 Reactive Red KE-3B Orthogonal Design Experiment Visual Analysis Table (Cotton K / S Value)

[0137] factor sodium sulfate Sodium carbonate pH adjustment temperature(℃) Experimental results Experiment 1 0 15 blank 85 8.43 Experiment 2 0 20 Ammonium sulfate 1g / L 90 6.08

[0138] Experiment 3 0 25 Ammonium acetate 1ml / L 95 6.21 Experiment 4 30 15 Ammonium sulfate 1g / L 95 13.54 Experiment 5 30 20 Ammonium acetate 1ml / L 85 16.71 Experiment 6 30 25 blank 90 10.22 Experiment 7 60 15 Ammonium acetate 1ml / L 90 12.1 Experiment 8 60 20 blank 95 16.12 Experiment 9 60 25 Ammonium sulfate 1g / L 85 19.75 Mean 1 6.907 11.357 11.59 14.963 Mean 2 13.49 12.97 13.123 9.467 Mean 3 15.99 12.06 11.673 11.957 extreme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com