Digital printing pulp and digital printing method

A technology of digital printing and slurry, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of high cost, complicated digital printing process and single function, achieve good health care function, improve anti-oxidation effect, and improve antibacterial performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

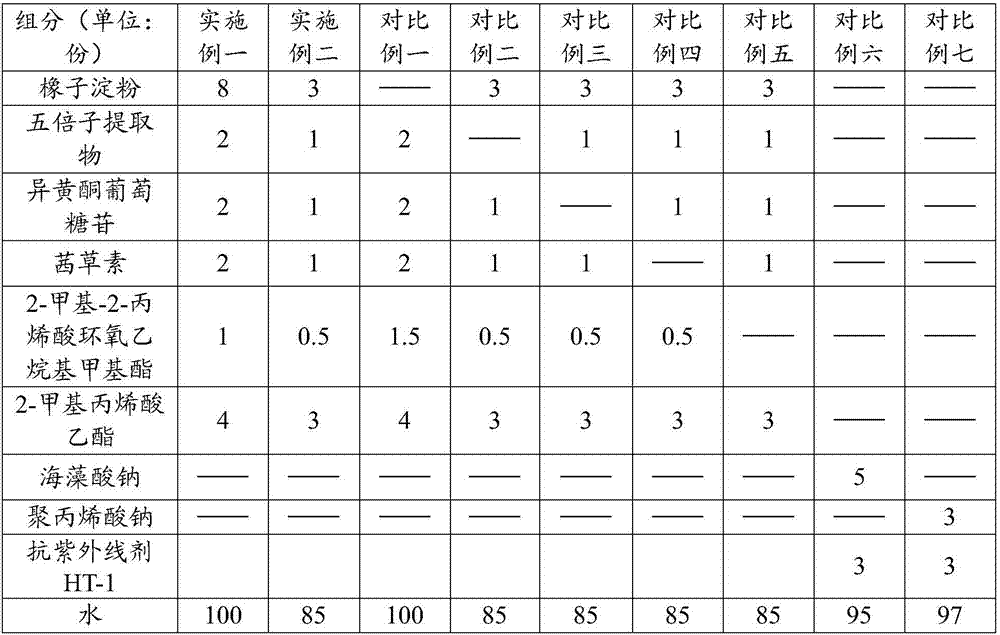

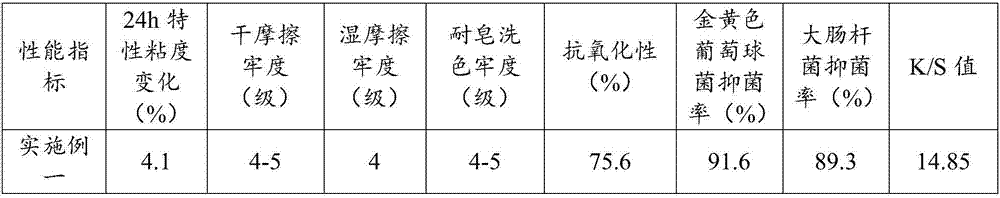

Examples

Embodiment 3

[0032] Silk power spinning fabric (76g / m 2 ) as an example, using Embodiment 1 and Embodiment 2, the digital printing slurry processing and finishing described in Comparative Example 1 to Comparative Example 5, the specific steps are: pre-treatment of fabric sizing—drying—digital printing—steaming—washing—drying dry - finished product.

[0033] Fabric sizing pre-treatment: soak the silk electrospun fabric in the digital printing slurry, the temperature of the digital printing slurry is 30°C;

[0034] Drying: select the temperature as 105°C, and the drying time is 10 minutes;

[0035] digital printing;

[0036] Steaming: select the temperature as 105°C, and the steaming time is 30 minutes;

[0037] Washing: choose pure water washing at 50°C;

[0038] Drying: select the temperature as 105°C, and the drying time is 10 minutes;

[0039] Finally, get the finished product, and conduct a performance test on the finished product, the test method is as follows:

[0040] Oxidation...

Embodiment 2

[0052] Compared with Example 2 and Comparative Example 2, it can be seen that after the gallnut extract is added, the fabric has a bacteriostatic rate of 88.7% to Staphylococcus aureus, and a bacteriostatic rate of 87.0% to Escherichia coli. antibacterial properties. After the digital printing slurry in Comparative Example 2 was placed for 24 hours, the viscosity dropped by 30%, and the stability of the digital printing slurry became worse, while after the digital printing slurry in Example 1 was placed for 24 hours, the viscosity decreased With only 4%, gallnut extract also has the effect of maintaining the stability of the digital printing slurry.

[0053] Comparing Example 2 with Comparative Example 3, it can be seen that after adding isoflavone glucoside, the oxidation resistance of the fabric is increased from 11.3% to 66.3%, and isoflavone glucoside can obviously improve the oxidation resistance of the fabric.

[0054]Embodiment two compares with comparative example fou...

Embodiment 1

[0064] Add antibacterial agent, antioxidant and color-fixing agent in the described digital printing slurry in embodiment one or embodiment two, described antibacterial agent, antioxidant and color-fixing agent do not form crystalline structure in colloidal solution and can play Respective functions, the digital printing slurry remains stable and can be used normally, and compared with the traditional digital printing pretreatment agent, the digital printing slurry in embodiment 1 or embodiment 2 has high stability. Digital printing is carried out using the digital printing paste in Embodiment 1 or Embodiment 2, and the steps of fabric sizing pre-treatment and post-finishing in the traditional digital printing process are combined into one step as the fabric sizing pre-treatment step, the process is simple and the energy consumption is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com