Special coated controlled-release fertilizer for peanuts in saline-alkali soil and preparation method of special coated controlled-release fertilizer

A special bag, saline-alkali land technology, applied in the field of controlled-release fertilizer, can solve the problems of time-consuming top dressing, difficult control of diseases and insect pests, weak plants, etc., and achieve the effect of saving labor costs and improving fertilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

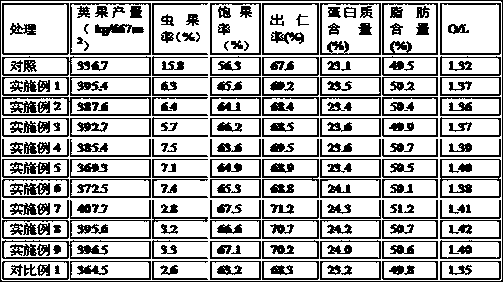

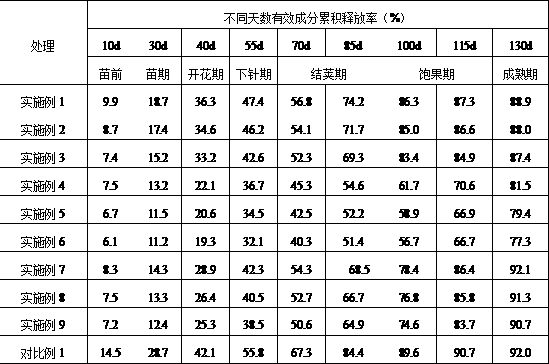

Examples

Embodiment 1

[0033] Coated controlled-release fertilizer for peanuts in saline-alkali soil is composed of an outer layer, a middle layer and an inner layer, and the raw materials and proportions of each layer are as follows:

[0034] Outer layer: 30 parts of urea formaldehyde powder, 40 parts of fermented manure of livestock and poultry, 30 parts of urea, 15 parts of hyperbranched polyamide, 0.5 part of ferrous sulfate, 0.05 part of chitosan oligosaccharide, 0.3 part of Shilax,

[0035] Middle layer: 85 parts of gypsum, 15 parts of humic acid, 0.5 parts of Shilashi, 65 parts of urea-formaldehyde powder,

[0036] Inner layer: 80 parts of potassium dihydrogen phosphate, 30 parts of urea, 20 parts of seaweed extract, 20 parts of adhesive.

[0037] The hyperbranched polyamide is an aliphatic hyperbranched polyamide, and the branching algebra is 2.0.

[0038] Preparation:

[0039] (1) Mix potassium dihydrogen phosphate, urea, seaweed extract and binder in the inner layer raw materials, granul...

Embodiment 2

[0043]Coated controlled-release fertilizer for peanuts in saline-alkali soil is composed of an outer layer, a middle layer and an inner layer, and the raw materials and proportions of each layer are as follows:

[0044] Outer layer: 30 parts of urea formaldehyde powder, 40 parts of fermented manure of livestock and poultry, 30 parts of urea, 15 parts of hyperbranched polyamide, 0.5 part of ferrous sulfate, 0.05 part of chitosan oligosaccharide, 0.3 part of Shilax,

[0045] Middle layer: 85 parts of gypsum, 15 parts of humic acid, 0.5 parts of Shilashi, 65 parts of urea-formaldehyde powder,

[0046] Inner layer: 80 parts of potassium dihydrogen phosphate, 30 parts of urea, 20 parts of seaweed extract, 20 parts of adhesive.

[0047] The hyperbranched polyamide is an aliphatic hyperbranched polyamide, and the branching algebra is 3.0.

[0048] The preparation method is the same as in Example 1.

Embodiment 3

[0050] Coated controlled-release fertilizer for peanuts in saline-alkali soil is composed of an outer layer, a middle layer and an inner layer, and the raw materials and proportions of each layer are as follows:

[0051] Outer layer: 30 parts of urea formaldehyde powder, 40 parts of fermented manure of livestock and poultry, 30 parts of urea, 15 parts of hyperbranched polyamide, 0.5 part of ferrous sulfate, 0.05 part of chitosan oligosaccharide, 0.3 part of Shilax,

[0052] Middle layer: 85 parts of gypsum, 15 parts of humic acid, 0.5 parts of Shilashi, 65 parts of urea-formaldehyde powder,

[0053] Inner layer: 80 parts of potassium dihydrogen phosphate, 30 parts of urea, 20 parts of seaweed extract, 20 parts of adhesive.

[0054] The hyperbranched polyamide is an aliphatic hyperbranched polyamide with a branching algebra of 4.0.

[0055] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com