Method for union dyeing of raw silk/Eco-wash wool (mercerized wool) interwoven fabric

A technique of same-color dyeing and woolen dyeing, applied in dyeing, textile and papermaking, etc., to achieve the effect of high color fastness, good same-color property and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Using bright red, silk wool plain weave fabric (raw silk 20%, Eco-wash wool 80%)

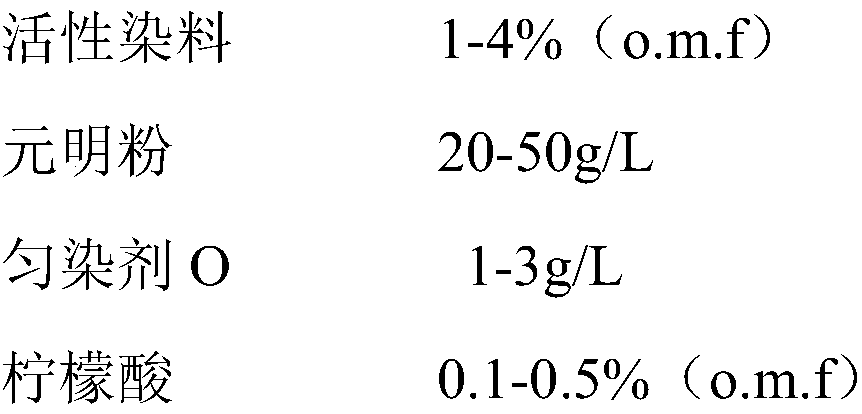

[0032] The dyeing process formula is:

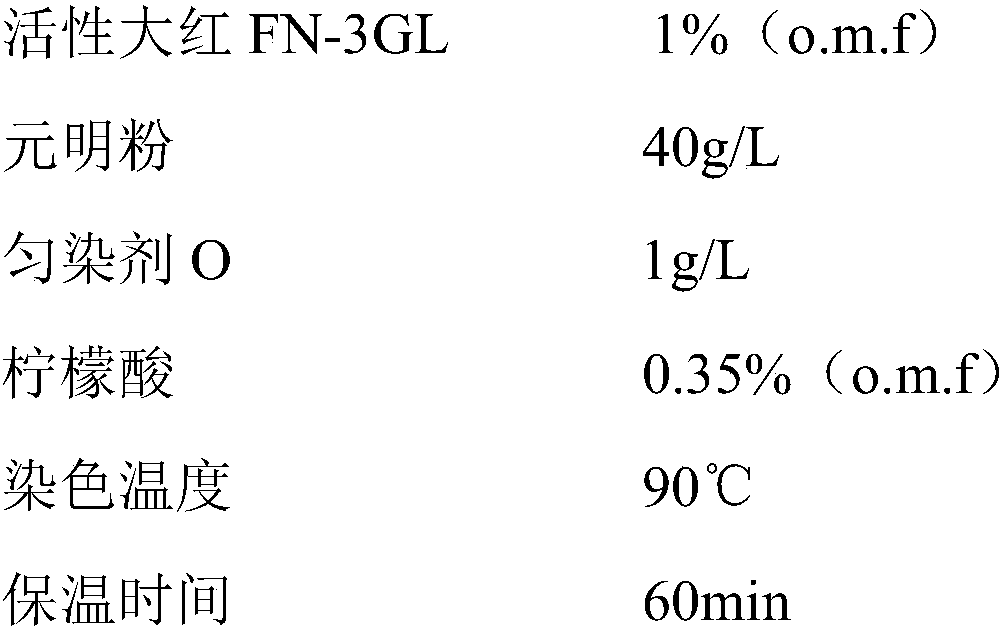

[0033]

[0034] According to the above dyeing formula, add reactive scarlet FN-3GL and leveling agent O to prepare the dyeing solution, add citric acid to adjust the pH value of the dyeing solution to 5.4-6.3; -2°C / min heating rate to 90°C, start to keep warm, add 1 / 2 of the sodium bicarbonate when keeping warm for 15 minutes, add the rest of sodium bicarbonate when keeping warm for 30 minutes, and keep warm for 60 minutes.

[0035] Take out the fabric after dyeing and carry out soaping, soaping process formula is:

[0036]

Embodiment 2

[0038] Dyeing process is identical with embodiment 1, difference is:

[0039] Rose red, silk wool plain weave fabric (raw silk 20%, Eco-wash wool 80%)

[0040] The dyeing process formula is:

[0041]

Embodiment 3

[0043] Dyeing process is identical with embodiment 1, difference is:

[0044] Light blue, silk wool plain weave (raw silk 20%, Eco-wash wool 80%)

[0045] The dyeing process formula is:

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com