Dyeing device for textile

A technology for dyeing and guiding fabrics, which is applied to the configuration of equipment for processing textile materials, processing textile material carriers, and spraying/jetting textile materials, etc. It can solve the problems of short residence time, slow rate of dye immersion into cloth, and slow dyeing rate. , to increase the residence time, improve the dyeing efficiency, and improve the dyeing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

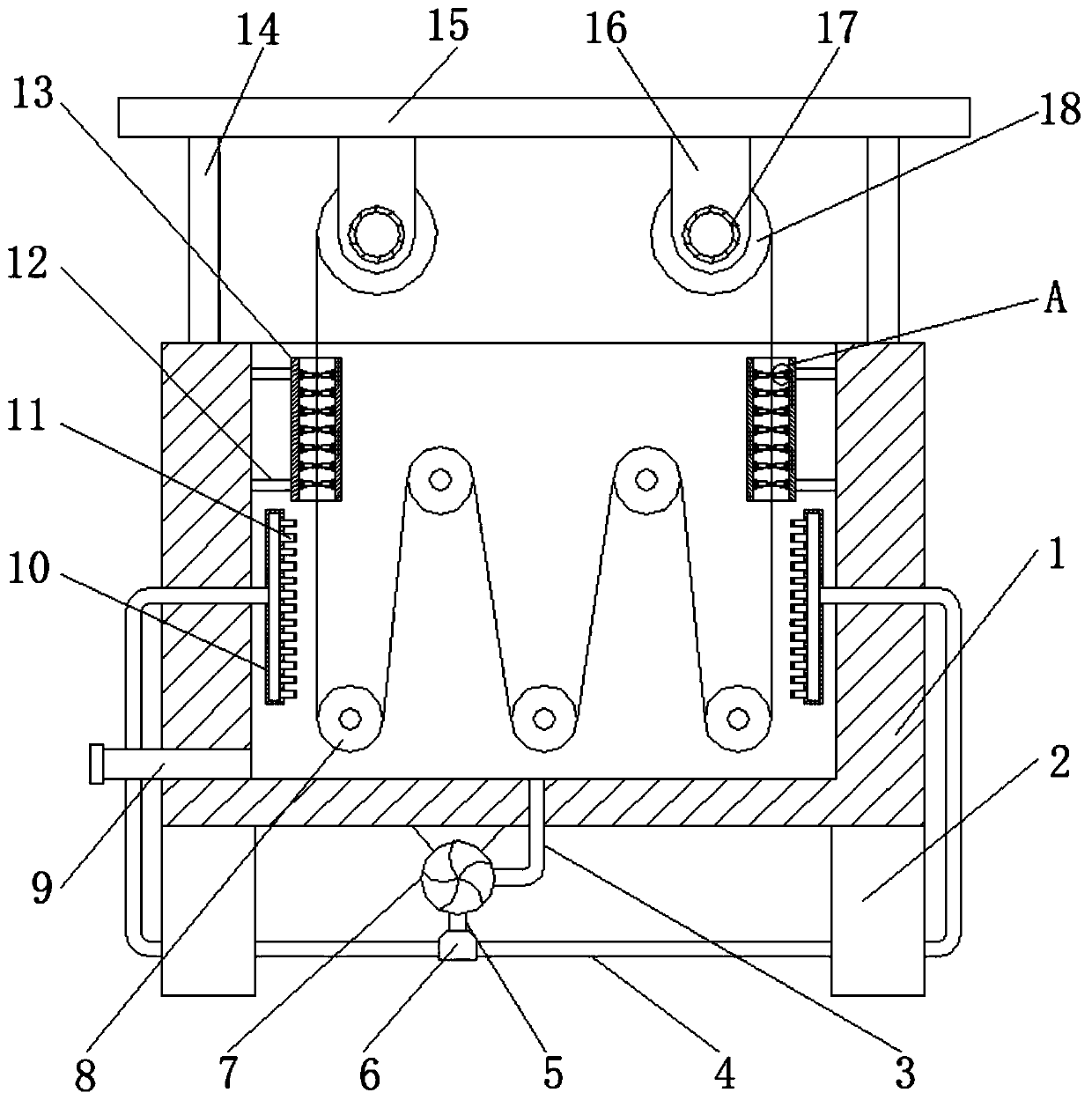

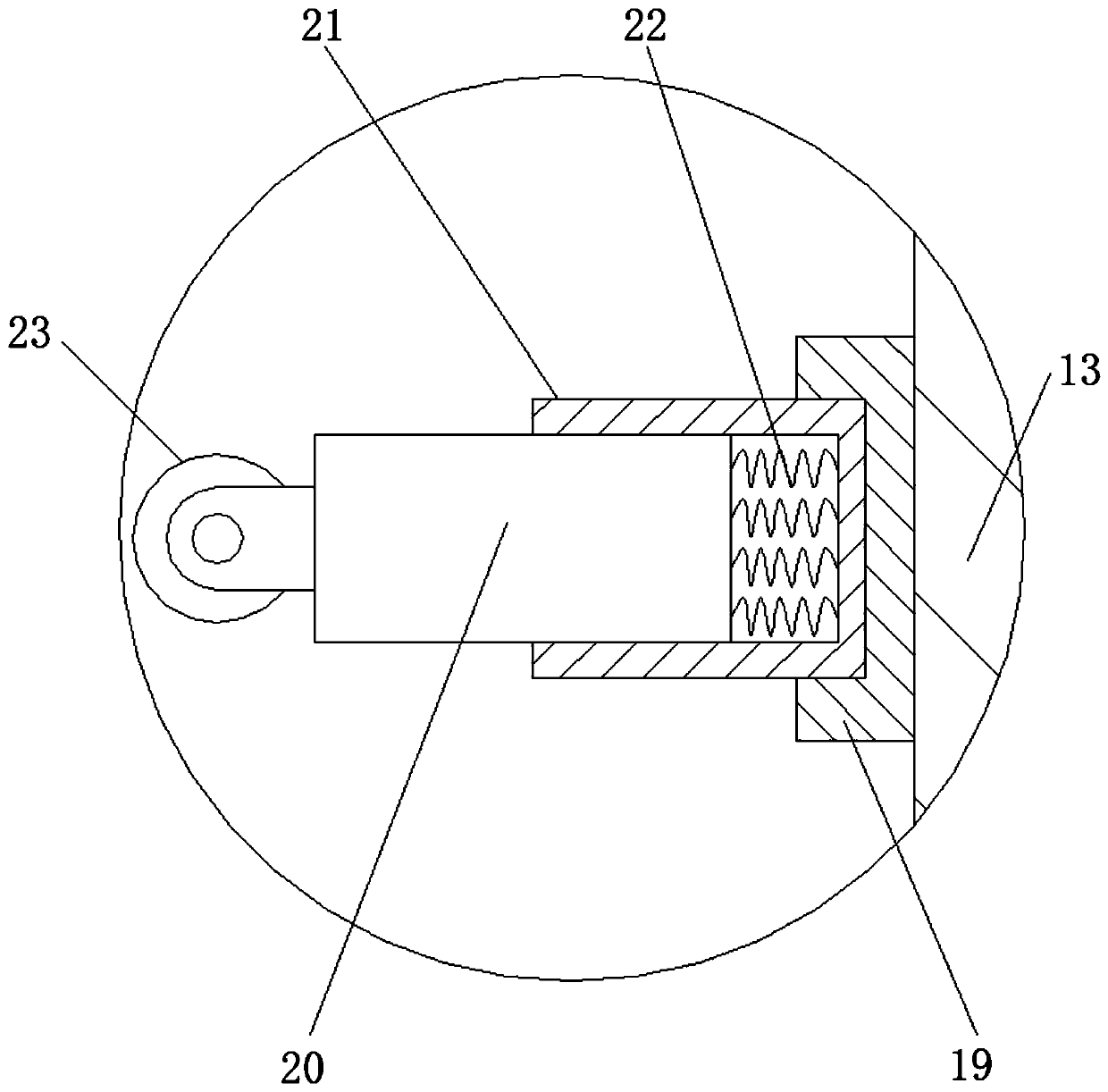

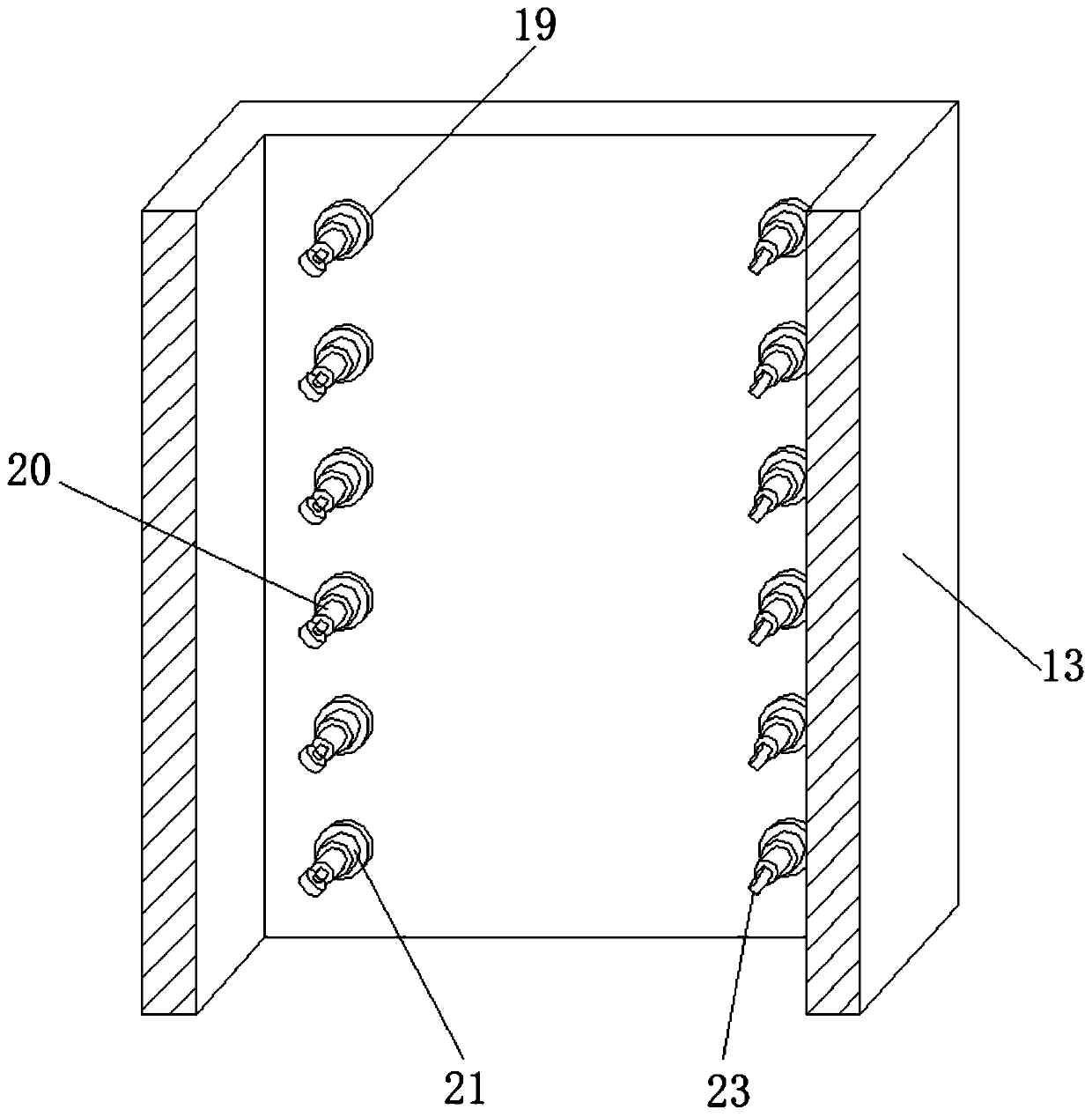

[0028] refer to Figure 1-4 , a textile dyeing device, comprising a dyeing box 1, the four corners of the top outer wall of the dyeing box 1 are welded with columns 14, and the top outer wall of the column 14 is welded with a top plate 15, and the bottom outer wall of the top plate 15 is close to both sides The positions of the fixed seats 16 are welded, and the number of the fixed seats 16 is two, and the outer wall of one side of the fixed seats 16 is connected with a motor 17 by bolts, and one end of the output shaft of the motor 17 is provided with a take-up roller 18, and the cloth dyeing box The inner wall of 1 is welded with equidistant and staggered horizontal bars, and the outer wall of the horizontal bar is rotatably connected with cloth guide roller 8, and the bottom outer wall of cloth dyeing box 1 is connected with water pump 7 by bolts, and one side of the outer wall of water pump 7 is connected by bolts. A suction pipe 3 is connected, one end of the suction pipe...

Embodiment 2

[0032] refer to Figure 5 , a cloth dyeing device for textile use. Compared with Embodiment 1, this embodiment also includes a blower 24 connected to the top outer wall of the dyeing box 1 by bolts, and an air guide pipe is arranged on one side of the outer wall of the blower 24 to guide the air. One end outer wall of the pipe is welded with a wind guide cover 25 .

[0033] Working principle: After dip-dyeing, you can open the liquid-changing tube 9 to export the dye, and then drive the motor 17 to work again, so that the cloth on the winding roller 18 is led to the other winding roller 18, and at the same time, the blower 24 is driven to work, which can be passed through the guide. The air cover 25 leads air and blows to the cloth, which effectively accelerates the air-drying speed of the cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com