Biological treatment method for wool blend fabric

A wool blending and biological treatment technology, applied in the biological treatment field of wool blended fabrics, can solve problems such as hand feel reduction, dyeing influence, environmental pollution, etc., and achieve the effects of reducing pilling performance, lowering dyeing temperature, and improving dyeing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

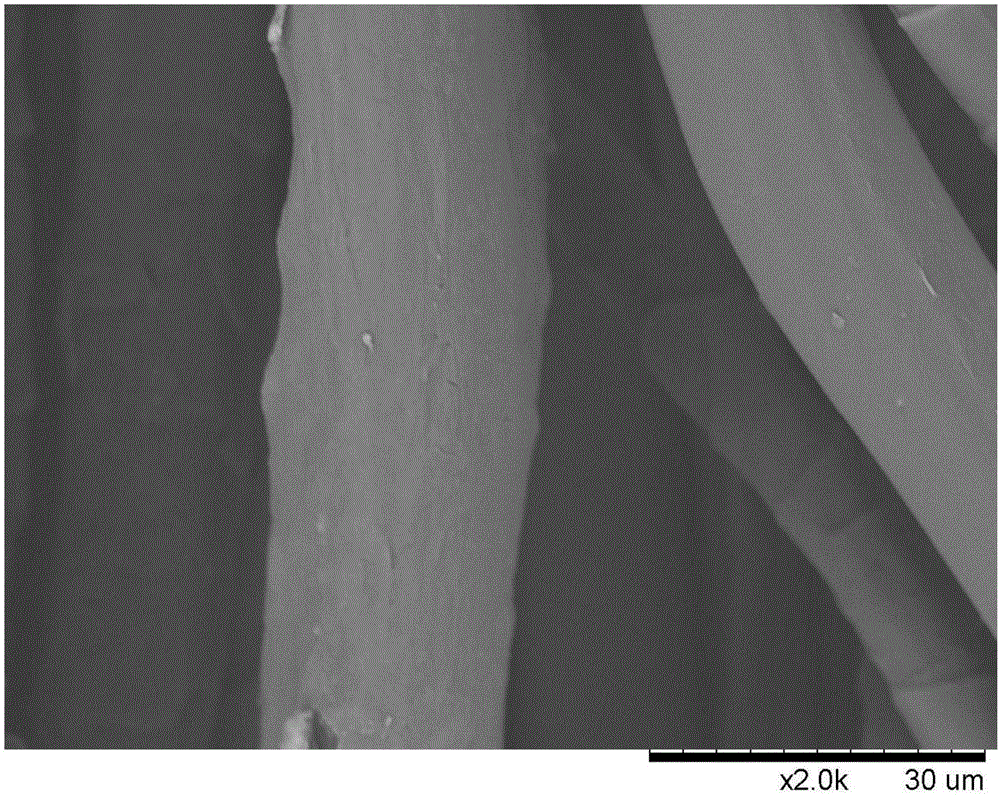

[0020] Strain Stenotrophomonas maltophilia DHHJ (CGMCCNo.2231), beef extract 5g / L, peptone 10g / L, NaCl 5g / L, agar 20g / L, pH7.4-7.6, liquid medium is beef extract 5g / L, peptone 10g / L, NaCl 5g / L, pH7.6. Fermentation medium components and dosage are glucose 10g / L, casein 2g / L, KCl0.4g / L, NaCl0.3g / L, NaCl 2 HPO 4 4g / L, KH 2 PO 4 0.3g / L, Tween-804g / L, pH7.5. Add 1% Stenotrophomonas maltophilia and 10% wool cloth to the fermented medium that has been prepared and sterilized, adjust the fermentation temperature to 30°C, the rotation speed to 300r, the fermentation time to 96h, and adjust the appropriate air pressure Strictly carry out the fermentation according to the amount of ventilation. After the end, rinse the fabric with hot water at 40°C, change the water for 20 minutes, 30 minutes, and 30 minutes for washing, and dry it naturally for later use. Among them, the SEM image of the wool cloth before dyeing after bacterial treatment is as follows figure 1 shown.

[0021] Af...

Embodiment 2

[0023] Strain Stenotrophomonas maltophilia DHHJ (CGMCCNo.2231), beef extract 5g / L, peptone 10g / L, NaCl 5g / L, agar 20g / L, pH7.4-7.6, liquid medium is beef extract 5g / L, peptone 10g / L, NaCl 5g / L, pH7.6. Fermentation medium components and dosage are glucose 10g / L, casein 2g / L, KCl0.4g / L, NaCl0.3g / L, NaCl 2 HPO 4 4g / L, KH 2 PO 4 0.3g / L, Tween-804g / L, pH7.5. Add 1% Stenotrophomonas maltophilia and 8% wool cloth to the fermented medium that has been prepared and sterilized, adjust the fermentation temperature to 35°C, the rotation speed to 400r, the fermentation time to 72h, and adjust the appropriate air pressure Strictly carry out the fermentation according to the amount of ventilation. After the end, rinse the fabric with hot water at 40°C, change the water for 20 minutes, 30 minutes, and 30 minutes for washing, and dry it naturally for later use.

[0024] After the dye bath is configured, add a specified amount of dye solution into a clean dye cup, raise the temperature to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com