Method for dyeing polylactic acid fiber fabrics with disperse dye under low temperature

A polylactic acid fiber and disperse dye technology, applied in the field of fabric dyeing, can solve the problems of increased loss of fiber physical and mechanical properties, and achieve the effect of low loss of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

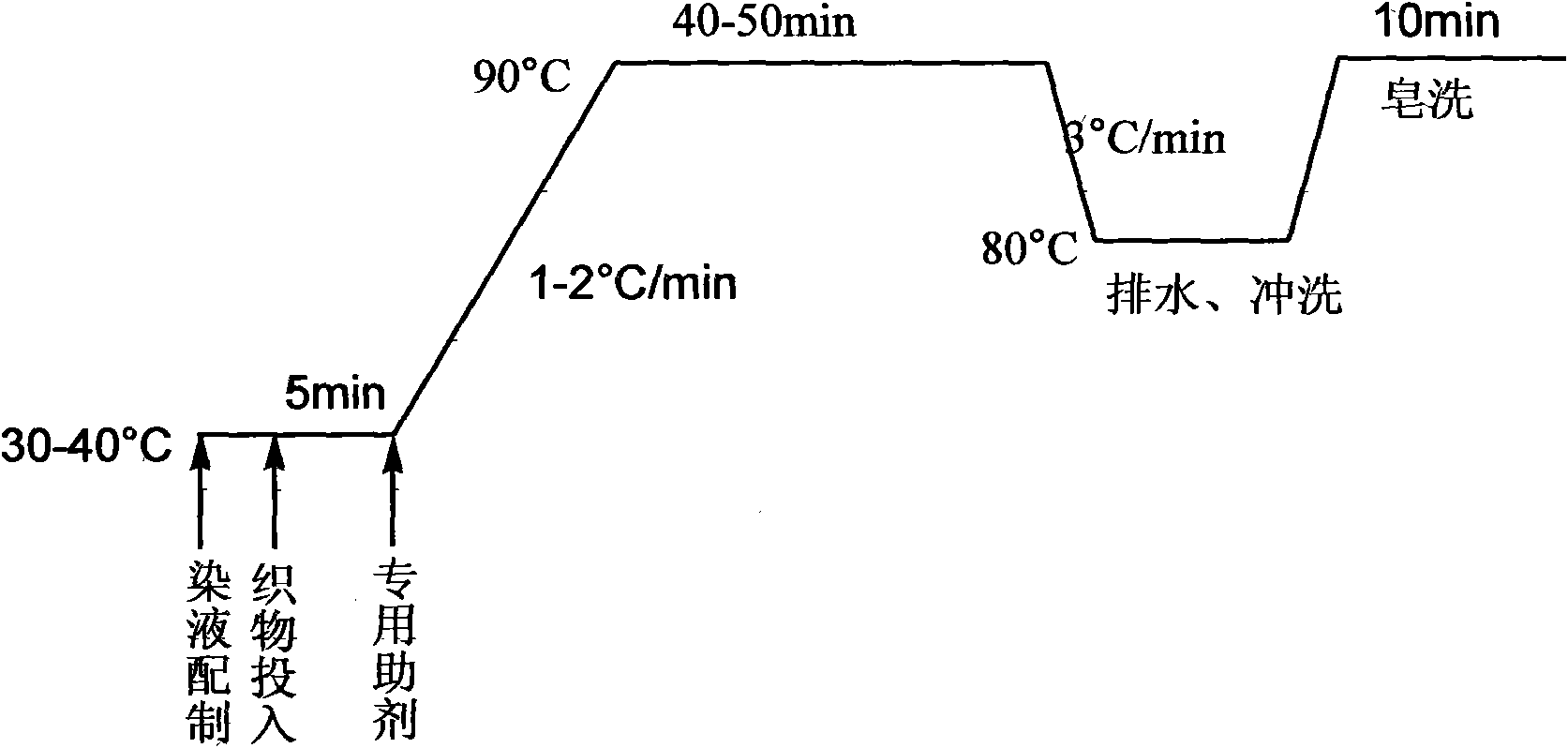

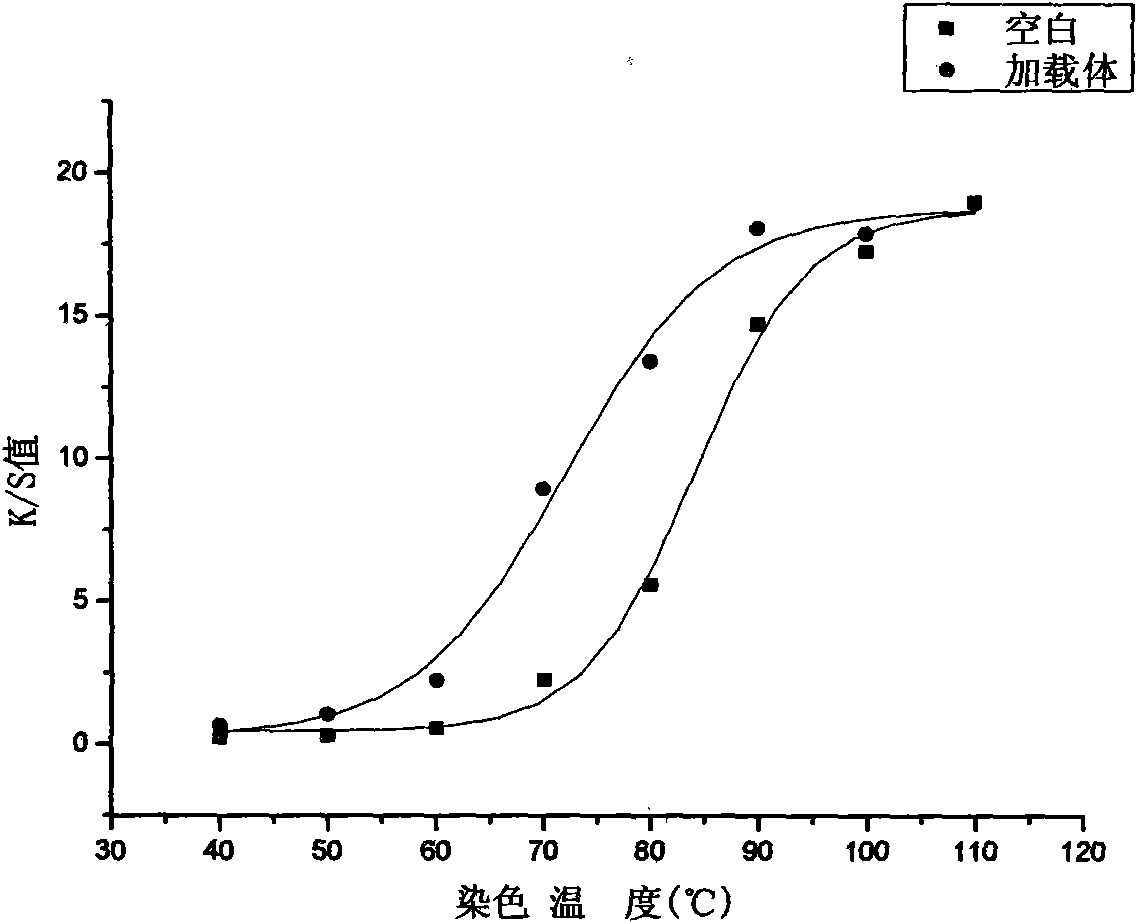

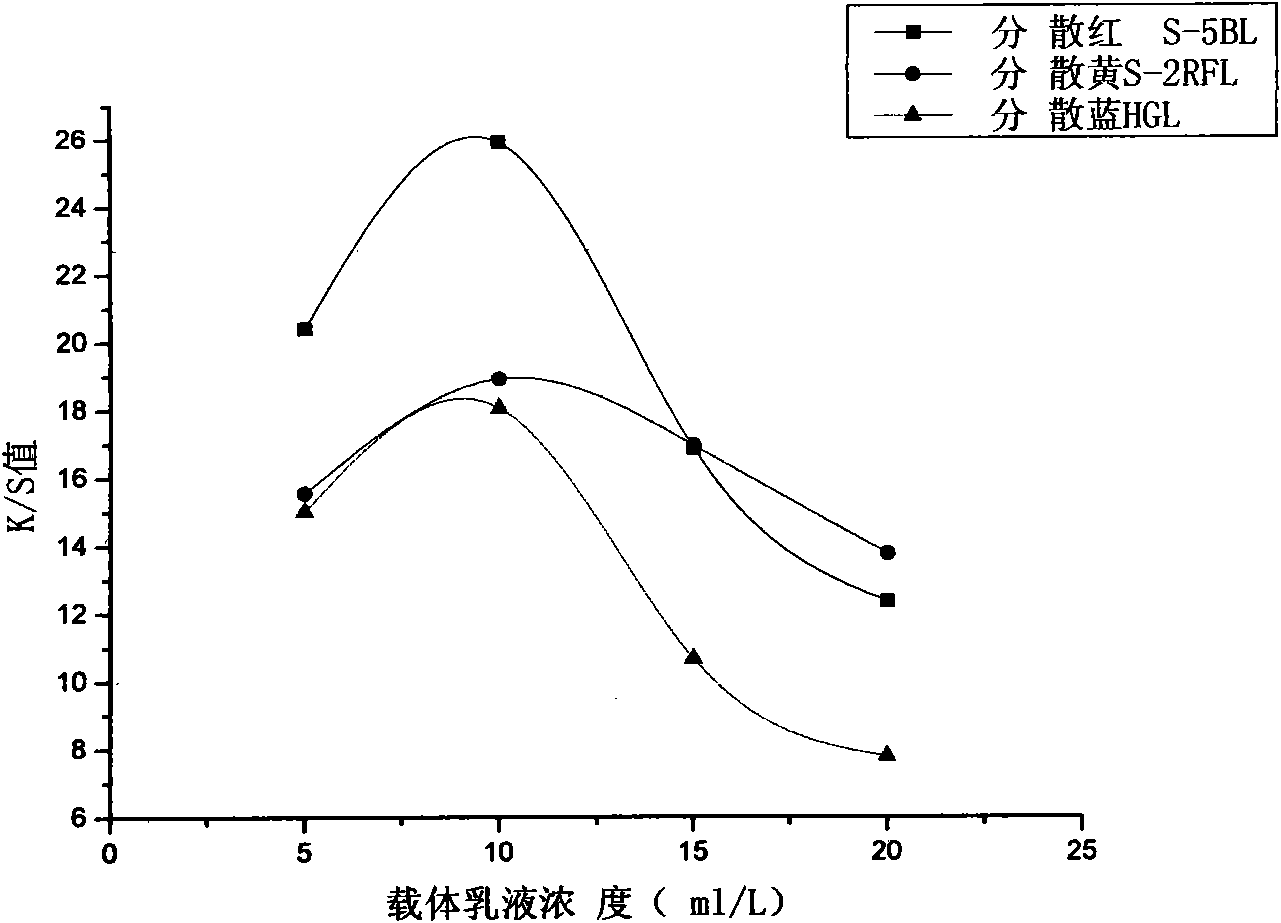

[0037] combine figure 1 As shown, the method for low-temperature dyeing of polylactic acid fiber fabrics with disperse dyes of the present invention comprises the following steps: according to the weight of the polylactic acid fiber fabrics dyed and the bath ratio of 10-20: 1, a certain amount of water is injected through calculation, and the Disperse dyes with good chemical materials, 1-2g / l dispersant, 1g / l ammonium sulfate, and then put them into the fabric to start running and wetting. After 5 minutes, add 10ml / l of special additives to raise the temperature at 1-2°C / min to 90°C, keep warm for 40-50 minutes, then cool down to 80°C at 3°C / min, drain and heat to 90°C, soap at a bath ratio of 1:10-20 for 10 minutes.

[0038] Dyeing Process Prescription:

[0039] Disperse dyes 0.5-4% (owf)

[0040] Special additive 10ml / l

[0041] Dispersant 1-2g / l

[0042] Ammonium sulfate 1g / l

[0043] Bath ratio 10-20:1

[0044] Soaping process prescription:

[0045] Soaping agent 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com