Low Salt and Low Alkali Reactive Dyeing Process by Air Dyeing

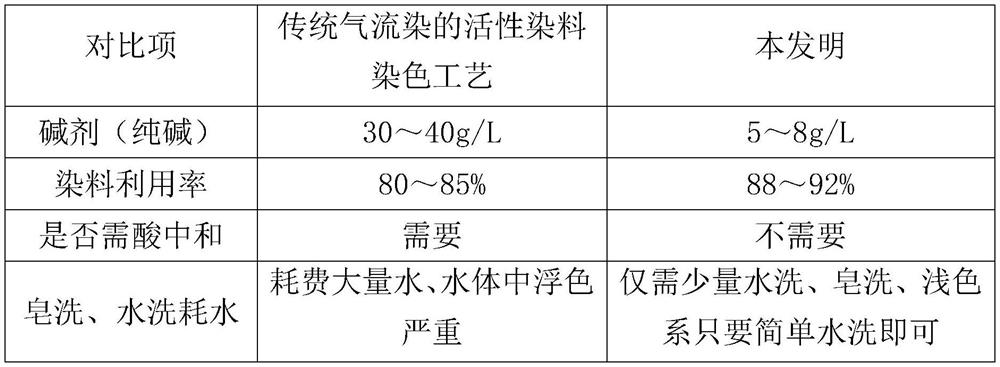

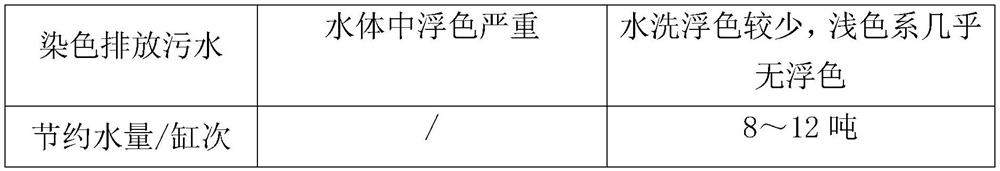

A technology of alkali activity and air flow, which is applied in the fields of dyeing, textile and papermaking, and spray/jet textile material treatment. It can solve the problems of difficult sewage treatment, low dye utilization rate, waste of water resources, etc., and reduce the difficulty of sewage treatment. , The effect of improving the utilization rate of dyestuffs and reducing the water consumption of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1. The low-salt and low-alkali active dyeing process of air dyeing comprises the following steps,

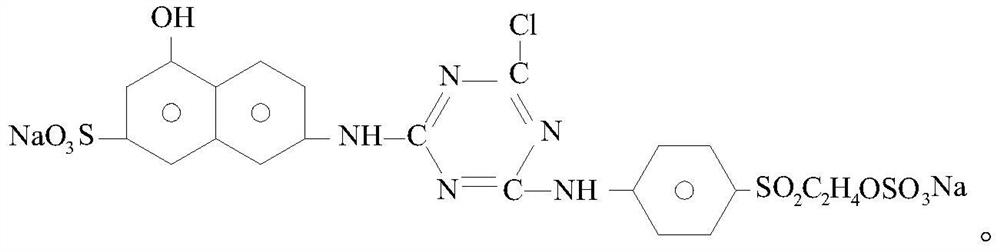

[0024] A. Choose the following dyes

[0025] For product A;

[0026] B, carry out pretreatment to all-cotton cloth according to conventional process, obtain B product;

[0027] C. Put product B into the air-flow atomization dyeing machine, connect product B end to end to form a rope, add 1.2% owf product A into the tank, the bath ratio is 1:4; The mass fraction of powder is 15%%; add soda ash until the concentration of soda ash in the tank is 2g / L; heat up to 30°C, and dye for 20min; add soda ash again until the concentration of soda ash in the tank is 5g / L; heat up to 55°C, Dyeing for 20 minutes; Drain to obtain product C;

[0028] D. Soap product C for 10 minutes and drain to obtain product D;

[0029] E. Wash and dry product D according to the conventional process to obtain a finished product.

Embodiment 2

[0030] Example 2. The low-salt and low-alkali active dyeing process of air dyeing comprises the following steps,

[0031] A. Choose the following dyes

[0032] For product A;

[0033] B. Pretreating the rayon cloth according to the conventional process to obtain product B;

[0034] C. Put product B into the air-flow atomization dyeing machine, connect product B end to end to form a rope, add 2.8% owf product A into the tank, the bath ratio is 1:3; The mass fraction of powder is 25%; add soda ash until the concentration of soda ash in the vat is 4g / L; heat up to 30°C and dye for 15min; add soda ash again until the concentration of soda ash in the vat is 8g / L; heat up to 65°C and dye 30min; Drain liquid to obtain product C;

[0035] D. Soap product C for 15 minutes and drain to obtain product D;

[0036] E. Wash and dry product D according to the conventional process to obtain a finished product.

Embodiment 3

[0037] Example 3. The low-salt and low-alkali active dyeing process of air dyeing is characterized in that: comprising the following steps,

[0038] A. Choose the following dyes

[0039] For product A;

[0040] B, carry out pretreatment to polyester-cotton cloth according to routine process, obtain B product;

[0041] C. Put product B into the air-flow atomization dyeing machine, connect product B end to end to form a rope, add 1.5% owf product A into the tank, the bath ratio is 1:4; The mass fraction of powder is 18%; add soda ash until the concentration of soda ash in the vat is 3g / L; heat up to 30°C and dye for 20min; add soda ash again until the concentration of soda ash in the vat is 6g / L; heat up to 55°C and dye 30min; Drain liquid to obtain product C;

[0042] D. Soap product C for 10 minutes and drain to obtain product D;

[0043] E. Wash and dry product D according to the conventional process to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com