Filtering and recycling device for leather dyeing

The technology of a recovery device and a filter device is applied in the field of filter recovery device for leather dyeing, which can solve the problems of poor filtering effect and low recovery rate, and achieve the effect of accelerating full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

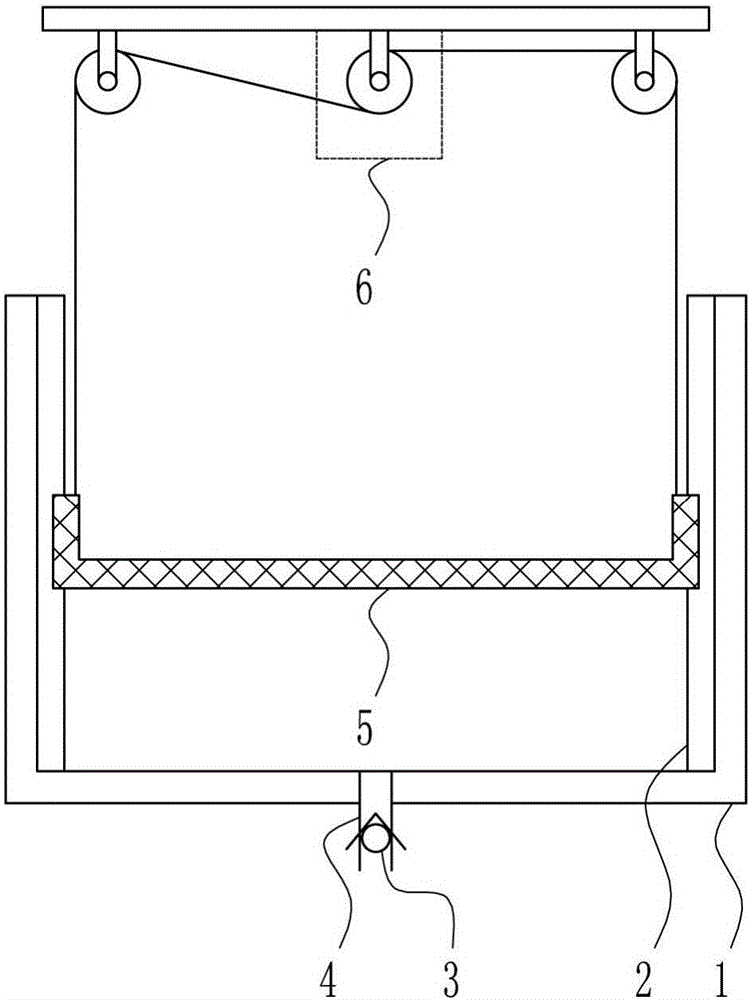

[0043] A filter recovery device for leather dyeing, such as Figure 1-9 As shown, it includes filter box 1, guide rail 2, one-way valve 3, first hose 4, filter device 5 and stirring device 6, the bottom of filter box 1 is connected with first hose 4, on the first hose 4 A one-way valve 3 is provided, and a guide rail 2 is provided on the left and right inner walls of the filter box 1 , a filter device 5 is provided on the guide rail 2 , and a stirring device 6 is provided on the filter device 5 .

Embodiment 2

[0045] A filter recovery device for leather dyeing, such as Figure 1-9 As shown, it includes filter box 1, guide rail 2, one-way valve 3, first hose 4, filter device 5 and stirring device 6, the bottom of filter box 1 is connected with first hose 4, on the first hose 4 A one-way valve 3 is provided, and a guide rail 2 is provided on the left and right inner walls of the filter box 1 , a filter device 5 is provided on the guide rail 2 , and a stirring device 6 is provided on the filter device 5 .

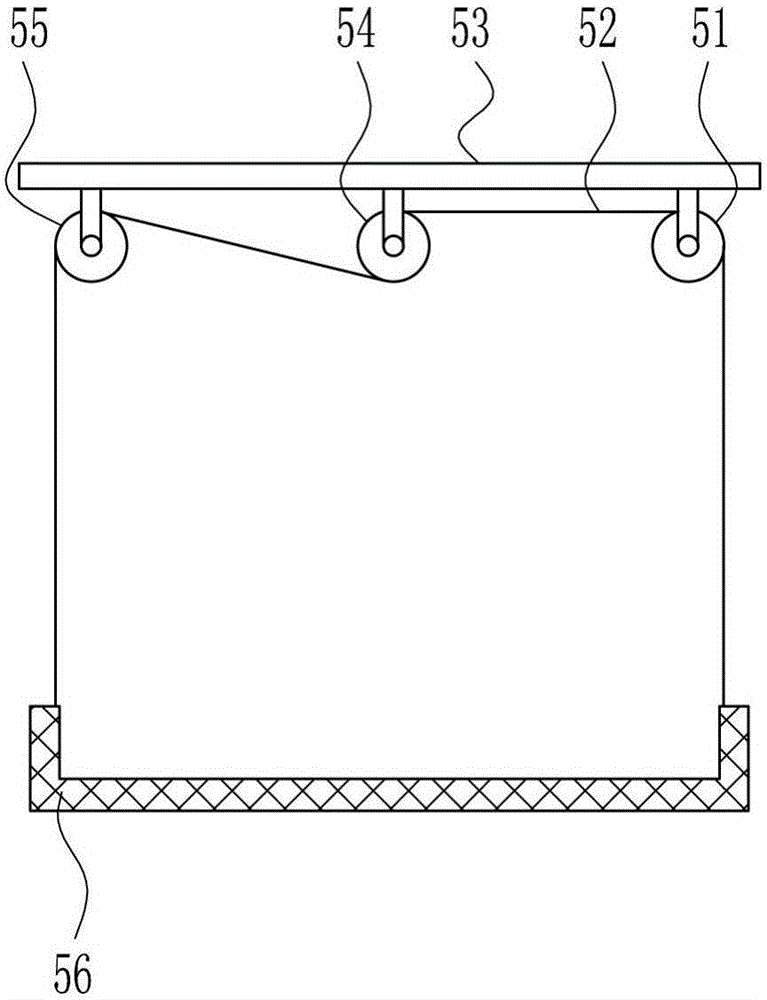

[0046] Filtration device 5 comprises first guide wheel 51, first stay cord 52, top plate 53, electric reel 54, second guide wheel 55 and filter net box 56, and the top of filter case 1 is provided with top plate 53, and top plate 53 The bottom is provided with the second guide wheel 55, the electric reel 54 and the first guide wheel 51 successively from left to right, the filter box 56 is arranged on the guide rail 2, the first stay rope 52 is wound on the electric reel 54, One end...

Embodiment 3

[0048] A filter recovery device for leather dyeing, such as Figure 1-9 As shown, it includes filter box 1, guide rail 2, one-way valve 3, first hose 4, filter device 5 and stirring device 6, the bottom of filter box 1 is connected with first hose 4, on the first hose 4 A one-way valve 3 is provided, and a guide rail 2 is provided on the left and right inner walls of the filter box 1 , a filter device 5 is provided on the guide rail 2 , and a stirring device 6 is provided on the filter device 5 .

[0049] Filtration device 5 comprises first guide wheel 51, first stay cord 52, top plate 53, electric reel 54, second guide wheel 55 and filter net box 56, and the top of filter case 1 is provided with top plate 53, and top plate 53 The bottom is provided with the second guide wheel 55, the electric reel 54 and the first guide wheel 51 successively from left to right, the filter box 56 is arranged on the guide rail 2, the first stay rope 52 is wound on the electric reel 54, One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com