Bottom material pre-coating machine for leather waterborne finishing agent and leather surface processing equipment and technology

A surface processing and water-based coating technology, applied in leather/skin/leather/hide chemical treatment equipment, leather surface treatment, small raw hide/large raw hide/leather/fur treatment, etc., can solve uneven edges and uneven leather surface Equality issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

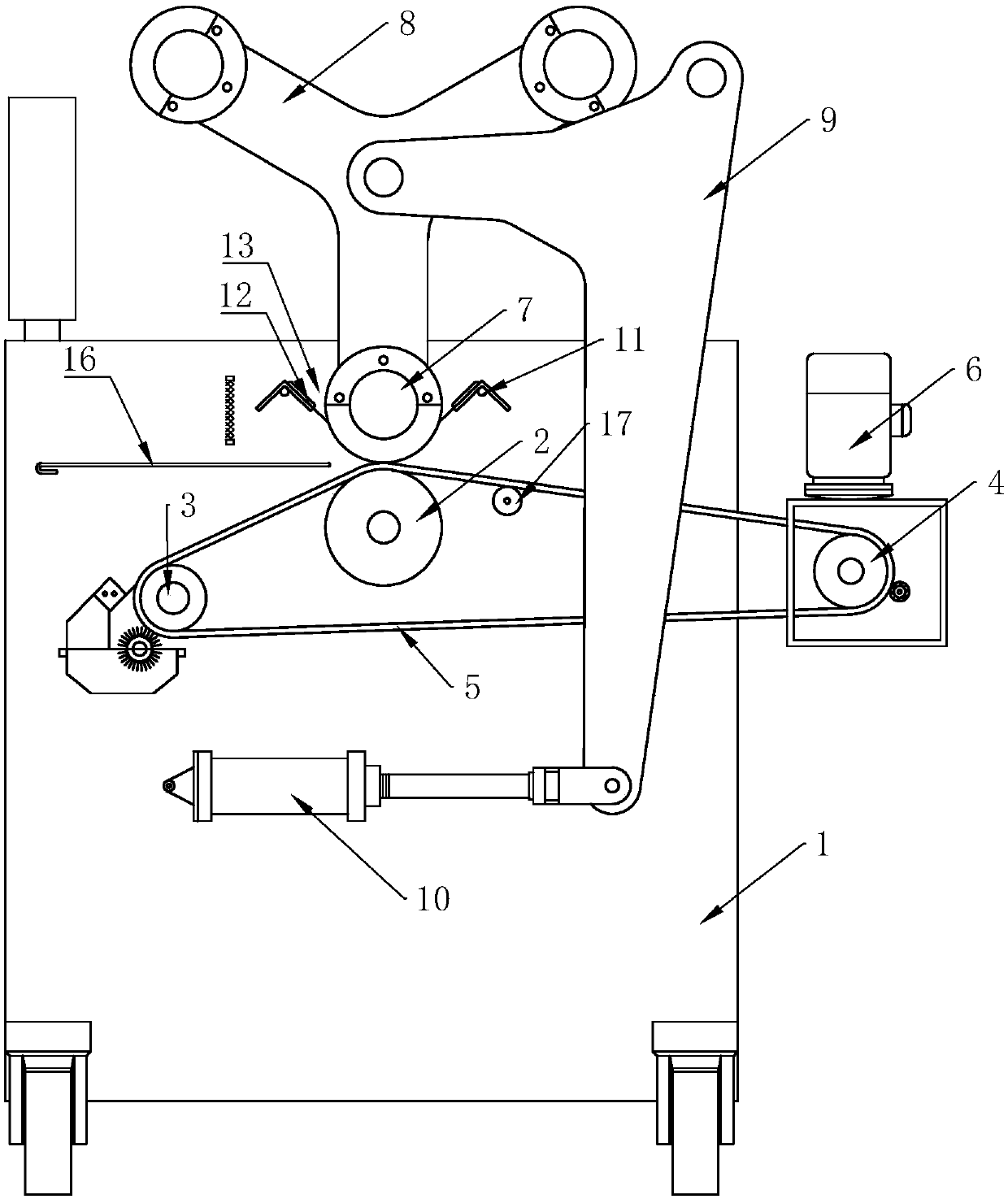

[0093] The leather surface processing technology adopts the leather surface processing equipment provided in the embodiment of the leather surface processing equipment, including the following steps:

[0094] S1. Use the leather grinding machine to grind the leather embryo: first open the dust collector, wait for the dust collector to run normally for 2-3 minutes, then turn on the leather grinding machine, and adjust the gap between the feeding belt of the leather grinding machine and the leather grinding roller 0.3-0.5mm smaller than the skin embryo to be treated;

[0095] S2. Use the hydraulic drive unit to adjust the gap between the finishing roller and the conveying belt to be 0.2-0.3 mm smaller than the thickness of the leather embryo; adjust the speed of the finishing roller and the belt drive roller to 2:1 , using a primer pre-coating machine to roll coat a layer of primer on the back of the leather embryo after grinding, at room temperature according to 20 ~ 30g / m 2 r...

Embodiment 2

[0118] The leather surface processing technology adopts the leather surface processing equipment provided in the embodiment of the leather surface processing equipment, including the following steps:

[0119] S1. Use the leather grinding machine to grind the leather embryo: first open the dust collector, wait for the dust collector to run normally for 2-3 minutes, then turn on the leather grinding machine, and adjust the gap between the feeding belt of the leather grinding machine and the leather grinding roller 0.3-0.5mm smaller than the skin embryo to be treated;

[0120] S2. Use the hydraulic drive unit to adjust the gap between the finishing roller and the conveying belt to be 0.2-0.3 mm smaller than the thickness of the leather embryo; adjust the speed of the finishing roller and the belt drive roller to 2:1 , using a primer pre-coating machine to roll coat a layer of primer on the back of the leather embryo after grinding, at room temperature according to 20 ~ 30g / m 2 r...

Embodiment 3

[0145] The leather surface processing technology adopts the leather surface processing equipment provided in the embodiment of the leather surface processing equipment, including the following steps:

[0146] S1. Use the leather grinding machine to grind the leather embryo: first open the dust collector, wait for the dust collector to run normally for 2-3 minutes, then turn on the leather grinding machine, and adjust the gap between the feeding belt of the leather grinding machine and the leather grinding roller 0.3-0.5mm smaller than the skin embryo to be treated;

[0147] S2. Use the hydraulic drive unit to adjust the gap between the finishing roller and the conveying belt to be 0.2-0.3 mm smaller than the thickness of the leather embryo; adjust the speed of the finishing roller and the belt drive roller to 2:1 , using a primer pre-coating machine to roll coat a layer of primer on the back of the leather embryo after grinding, at room temperature according to 20 ~ 30g / m 2 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com